When we talk about industrial manufacturing plants like aircraft and automobile manufacturing, the biggest challenge is moving loads around at the time of assembly. Assembly is the final stage, where all individual components are put together to complete the production of individual units (like aircraft and vehicles). Continue reading “How Air Bearing Technology Enhances Assembly Line Operations”

Category: Blog

Navigating Permit Requirements: A Guide to Over-Dimensional Load Transportation

Transporting an over-dimensional load requires extensive planning and adherence to many procedures. You will require licenses to carry loads that exceed standard dimensions. The heavy load moving process that exceeds the size and weight limitations established by transportation authorities has special requirements that need to be fulfilled; otherwise, there will be consequences. If you follow these requirements, you can operate your automobile safely. Continue reading “Navigating Permit Requirements: A Guide to Over-Dimensional Load Transportation”

Navigating the Complexities of Heavy Load Logistics

When we say heavy load logistics, we don’t mean moving heavy objects by hand, but we’re referring to moving loads weighing numerous tons through specialized equipment. While lifting heavy weights by hand puts the workers at the risk of improper posture and injuries, lifting heavy loads can lead to catastrophic injuries and damages if not done cautiously. Continue reading “Navigating the Complexities of Heavy Load Logistics”

Exploring Load Positioning Techniques for Heavy Machines

Heavy machines are crucial to various industries, including construction, manufacturing, and logistics. These machines often handle large and heavy loads, making load positioning a critical aspect of their operation. Proper load positioning techniques ensure safety and optimize efficiency and productivity. This article will explore some effective load positioning techniques for heavy machines.

Understanding Load Positioning Techniques

Load positioning techniques involve determining the optimal placement of a load on a heavy machine to achieve balance, stability, and safe handling. Several factors influence load positionings, such as the machine’s capacity, the load’s weight distribution, and the intended task. Let’s delve into some commonly used techniques:

1. Center of Gravity Calculation

Calculating a load’s center of gravity (CoG) is vital to achieving stability during transportation or lifting operations. By determining the CoG, operators can position the load accordingly to maintain balance. Various mathematical formulas and computer software are available to calculate the CoG accurately.

2. Symmetrical Load Placement

When dealing with a symmetrical shape, such as a rectangular container, placing the load symmetrically on the machine helps distribute the weight evenly. This technique minimizes the risk of tipping and ensures stability throughout the operation.

3. Counterweight Systems

Counterweight systems are commonly used in cranes and other heavy-lifting equipment. These systems consist of additional weights attached to the opposite side of the load. Operators can offset the load’s weight by strategically positioning the counterweights, maintaining balance, and preventing the machine from tipping.

4. Load Balancing Algorithms

In modern heavy machines, load positioning can be optimized using load-balancing algorithms. These algorithms use sensors and real-time data to calculate the optimal load position. By adjusting the machine’s hydraulics or other control mechanisms, the algorithm ensures the load is evenly distributed, enhancing stability and reducing the strain on the machine.

5. Adjustable Load Attachments

Certain heavy machines like forklifts feature adjustable load attachments, such as extendable forks. These attachments allow operators to position the load precisely, aligning it with the machine’s center of gravity. Operators can ensure a secure and well-balanced load by adjusting the attachment’s width or length.

6. Tilt and Rotation Control

Load positioning techniques also involve controlling the tilt and rotation of heavy machines. For instance, cranes may utilize hydraulic systems that enable precise control over the load’s rotation. Adjusting the tilt and rotation allows operators to position the load in the desired orientation, facilitating safe and efficient handling.

Benefits and Applications

Efficient load positioning techniques benefit operators and businesses in various industries. Some notable advantages include:

- Enhanced Safety:Proper load positioning minimizes the risk of accidents, such as tipping or load shifts, ensuring the safety of both operators and nearby personnel.

- Improved Efficiency:Optimal load positioning reduces the strain on heavy machines, improving their efficiency and prolonging their lifespan. It also reduces the time required for load-handling operations.

- Increased Productivity:By utilizing effective load positioning techniques, businesses can streamline their operations, resulting in increased productivity and reduced downtime.

- Cost Savings:Preventing accidents and minimizing machine strain can save costs by reducing repair and maintenance expenses.

Load positioning techniques find applications in various industries, including construction sites, warehouses, manufacturing facilities, and ports. Whether lifting heavy materials, transporting oversized goods, or loading and unloading cargo, these techniques ensure safe and efficient operations.

To Sum Up

Take advantage of Hovair Systems’ expertise and explore their comprehensive range of solutions today. With Hovair Systems, you can elevate your load positioning capabilities, improve productivity, and enhance workplace safety.

Don’t settle for subpar load positioning techniques. Contact Hovair Systems now and unlock the full potential of your heavy machines. Experience the difference that proper load positioning can make in your operations and gain a competitive edge in your industry.

Best Practices and Guidelines for Risk Mitigation For Heavy Load Transport

Heavy load transport involves the transportation of oversized and overweight goods, which can present significant challenges and risks. To ensure the timely delivery of heavy loads, it’s essential to implement best practices and guidelines for risk mitigation. This article will explore a few key strategies and considerations to mitigate risks associated with heavy-load transport. Continue reading “Best Practices and Guidelines for Risk Mitigation For Heavy Load Transport”

The Future of Equipment Handling: Innovations and Trends Shaping the Industry

In today’s rapidly advancing world, equipment handling trends play a crucial role in various sectors, from manufacturing to construction and logistics. As technology develops at a fast pace, it is imperative for businesses to adapt and embrace innovative solutions for safer and more efficient equipment handling. This blog will explore the exciting developments and innovations shaping the future of equipment handling trends. Continue reading “The Future of Equipment Handling: Innovations and Trends Shaping the Industry”

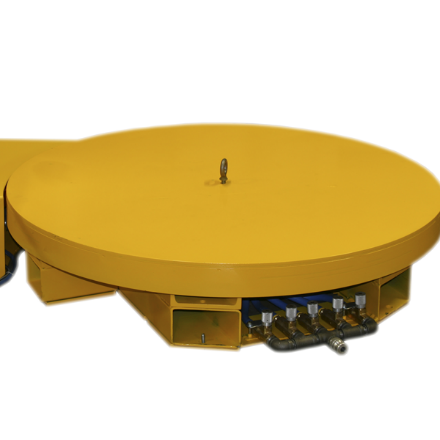

The Impact Of Vehicle & Showroom Turntables On Auto Sales

A vehicle turntable is a rotating platform that is used to position vehicles and allow visitors to look at the vehicle from all angles. They are typically used in garages, showrooms and other areas where space is limited. Vehicle turntables can be either manual or motorized. Manual turntables are rotated by hand, while motorized turntables are rotated by a motor. Continue reading “The Impact Of Vehicle & Showroom Turntables On Auto Sales”

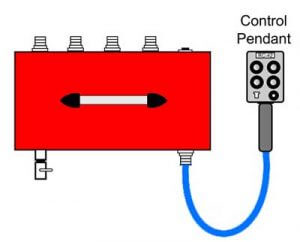

Why Are Remote Control Units Considered The Future Of Material Handling Automation

Remote control units are wireless or wired devices used to operate hoists, cranes, and other material handling equipment. They allow the operator to control the equipment from a safe distance, reducing the risk of accidents and injuries. Continue reading “Why Are Remote Control Units Considered The Future Of Material Handling Automation”

How to Minimize Operational Costs & Maximize Workplace Safety Through Flexible Material Handling Solutions

Have you ever considered deploying flexible material handling solutions in your industrial space? This sort of equipment is used by all kinds of companies to move heavy loads as efficiently and safely as possible. It helps everyone from mass transit manufacturers seeking ways to efficiently move train parts during maintenance to power generation experts who want to lift solar panels into position at their clients’ premises. Continue reading “How to Minimize Operational Costs & Maximize Workplace Safety Through Flexible Material Handling Solutions”

How Industrial Turntables Boost Productivity In Manufacturing Aircrafts?

Industrial turntables are a versatile tool that can be used in a variety of ways in the manufacturing sector. They can help to improve efficiency, safety, and quality control in aircraft manufacturing. Continue reading “How Industrial Turntables Boost Productivity In Manufacturing Aircrafts?”

Mastering Material Handling: The Comprehensive Guide to the Industry’s Top Material Handling Equipment

Efficient material handling has now become a necessity to reduce costs, improve productivity, increase safety, enhance customer service, and promote environmental sustainability. Continue reading “Mastering Material Handling: The Comprehensive Guide to the Industry’s Top Material Handling Equipment”

How Are Vehicle Turntables Streamlining Automotive Workshops?

A vehicle turntable offers a convenient and effective solution for a variety of cases in the car industry. They are a versatile solution for turning vehicles around in a limited space, making them useful in a variety of applications where space is limited or maneuverability is important. Continue reading “How Are Vehicle Turntables Streamlining Automotive Workshops?”

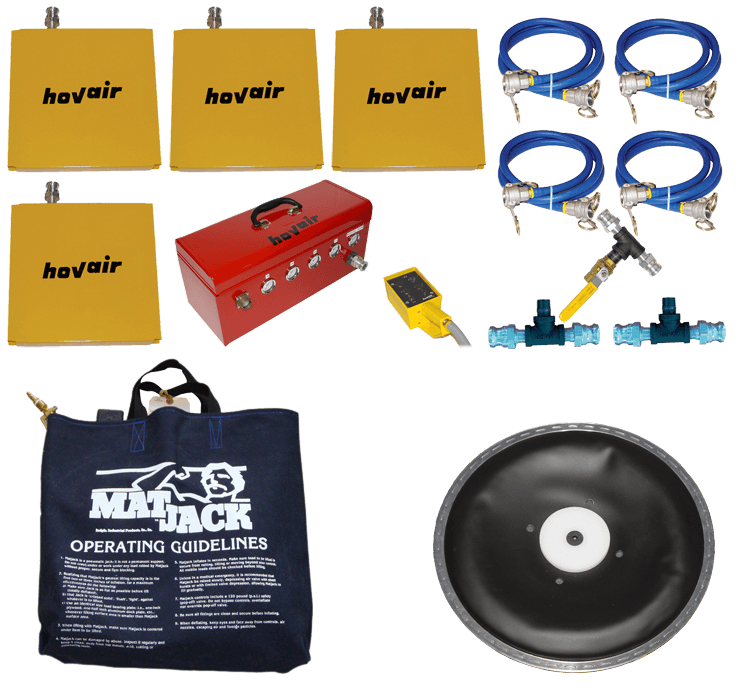

Lifting Jacks With Air Bearings Guide: The Uses Of Lifting Jacks With Air Bearings

Lifting jacks with air bearings are used in a variety of applications, including moving heavy machinery, positioning large equipment, and installing or removing heavy components. Continue reading “Lifting Jacks With Air Bearings Guide: The Uses Of Lifting Jacks With Air Bearings”

The Key Role Of Rigging Equipment Uses in Efficient Material Handling

Rigging equipment is essential for efficient material handling, improving safety, productivity, and reducing costs. Continue reading “The Key Role Of Rigging Equipment Uses in Efficient Material Handling”

The Science Behind Air Beams – A Beginner’s Air Beam Guide

Air beams are often used to move heavy loads over short distances, such as within a factory or warehouse setting. They are particularly useful when moving delicate or sensitive loads that can be easily damaged by traditional material handling methods, such as dragging or rolling. Continue reading “The Science Behind Air Beams – A Beginner’s Air Beam Guide”

What is Material Handling? Principles, Benefits & Equipment

While warehouses are characterized as being full of activity, they don’t necessarily have to be labor-intensive or chaotic. Having the proper equipment and systems can help improve the efficiency and productivity of warehouse workers. This can be done through specialized equipment and material handling solutions. Continue reading “What is Material Handling? Principles, Benefits & Equipment”

6 Material Handling Equipment Trends To Watch In 2023

In our rapidly changing world; technology, and information advances are transforming industries at an unprecedented pace, and the material handling industry is no exception. Continue reading “6 Material Handling Equipment Trends To Watch In 2023”

Understanding The Importance Of Ergonomic Equipment

Material handling is the science of receiving, packing, moving, or storing material or finished products. But manual material handling is one of the leading causes of workplace injuries in manufacturing plants, warehouses, and distribution centers across the globe. Continue reading “Understanding The Importance Of Ergonomic Equipment”

Tips for Optimizing Warehouse Layout For Safety And Efficiency

It’s no secret that workplace accidents are costly; not only financially but also in terms of employee health and morale. Manual material handling systems expose employees to various potentially dangerous and strenuous activities that threaten their safety and your facility’s productivity. Continue reading “Tips for Optimizing Warehouse Layout For Safety And Efficiency”

Ergonomic Lift Tables: The Ultimate Solution for Reducing Workplace Injuries

Lift deck beam sets are extremely low-profile, resembling a pallet truck. They may simply slip underneath a cargo and use the air lifter facility in the higher beam decks to raise the pallet off the ground. Continue reading “Ergonomic Lift Tables: The Ultimate Solution for Reducing Workplace Injuries”

How Industrial Turntables Can Improve Logistics and Reduce Costs

industrial turntables are very versatile products and have multiple applications in various industries. And no matter what application they are used for, the main role of industrial turntables that we have to consider is improving logistics and reducing costs. Continue reading “How Industrial Turntables Can Improve Logistics and Reduce Costs”

Air Casters: Top Reasons to Take a Fresh Look at the Revolutionary Technology

Countless unique ways are followed for moving heavy loads or equipment in industries across the globe. Previously, heavy machinery movers and riggers relied on equipment like lift trucks, rollers, and cranes to inch massive machines or transport oversized loads into place. Continue reading “Air Casters: Top Reasons to Take a Fresh Look at the Revolutionary Technology”

Top Material Handling Equipment Items to Increase Efficiency in A Warehouse

Load handling tool includes various items such as automatic guided vehicles, ergonomic equipment, and storage tools, which helps store and move goods in a warehouse. You’ll find such equipment being extensively used in various industries. These items are quite versatile and can be used in various applications. Continue reading “Top Material Handling Equipment Items to Increase Efficiency in A Warehouse”

How to Repair Heavy Equipment Quickly and Accurately Using the Power of Compressed Air

Have you ever heard of air compression tools? As you might’ve guessed, these are tools that use compressed air to aid with everything from moving heavy loads to rotating materials precisely. Air compression tools are popular among manufacturing companies because they help with quick and accurate equipment repairs. Continue reading “How to Repair Heavy Equipment Quickly and Accurately Using the Power of Compressed Air”

3 Ways to Boost Warehouse Staff Productivity Through Ergonomic Equipment and Moving Systems

According to a book published by warehouse management experts, one of the primary methods of measuring warehouse staff productivity is labor hours utilization. This refers to the number of hours staff spend working as a percentage of their total hours in the warehouse; The higher their utilization rate, the more productive they are! Continue reading “3 Ways to Boost Warehouse Staff Productivity Through Ergonomic Equipment and Moving Systems”

How to Move Heavy Loads Easily Using Efficient Material Handling Solutions

Are you looking for ways to move heavy loads easily without exceeding your budget? If so, you’ll love investing in efficient material handling solutions that rely on the power of compressed air! This kind of ergonomic equipment boosts worker productivity while making workplaces safer for staff members. Continue reading “How to Move Heavy Loads Easily Using Efficient Material Handling Solutions”

What Are the Main Ways to Optimize Warehouse Operations?

How do you optimize warehouse operations to make production efficient and maintain a healthy bottom line? In most cases, this is achieved by investing in innovative material handling equipment that helps manufacturers store, transport, and load/unload products. That’s why we’ve summarized how material handling solutions help manufacturers to optimize warehouse operations and maximize profits. Continue reading “What Are the Main Ways to Optimize Warehouse Operations?”

How to Transport Heavy Materials Efficiently Using Air Compressor Tools

Can’t find a way to transport heavy materials efficiently? Tired of spending a hefty chunk of your budget on energy and labor costs due to operational inefficiencies resulting from the use of outdated material handling equipment? If this sounds familiar, it’s time to make the most of air compressor tools! Continue reading “How to Transport Heavy Materials Efficiently Using Air Compressor Tools”

How to Reduce Product Damage in Warehouses UsingAir-Bearing Moving Systems

According to an article published in the American Journal of Transportation, over $15 billion in consumer goods are rendered unsalable after being damaged in the supply chain. Fortunately, this massive amount of money can be saved by implementing simple yet effective solutions like making use of air-bearing moving systems. Continue reading “How to Reduce Product Damage in Warehouses UsingAir-Bearing Moving Systems”

Workplace Injuries That Material Lifting Equipment Can Prevent

Ergonomic and safety hazards can result in increased workplace injuries which can harm the company’s bottom line. Tasks like manual material handling are common in all industries. Continue reading “Workplace Injuries That Material Lifting Equipment Can Prevent”

Elements Of A Sustainable Warehouse: Why You Should Make Your Warehouse Green

Warehouses are important company assets once only meant to store enormous bulks of valuable raw materials or finished products. Today, they directly impact a company’s reputation and bottom line as they play a critical role in the corporate social responsibility consumers emphasize on enterprises worldwide. Continue reading “Elements Of A Sustainable Warehouse: Why You Should Make Your Warehouse Green”

Industrial Turntables: What They Are And How To Use It

If you’ve ever had to dangerously back out into a busy street because of your driveway’s limited space, then you may be interested in learning more about industrial turntables, a piece of innovative commercial equipment that has become increasingly popular among businesses and individuals alike. Continue reading “Industrial Turntables: What They Are And How To Use It”

The Evolution of Material Handling Equipment

Material handling has been a crucial process used in a broad range of industries for centuries—consumer goods, military and defense, vehicle manufacturing, shipyard, reel and roll handling, spacecraft and aircraft manufacturing, and so on. Continue reading “The Evolution of Material Handling Equipment”

Things You Need To Know About Oversize Load Transportation

One of the most important factors that employers consider when it comes to the well-being of their workers is the availability of a proper workspace. According to the Bureau of Labor Statistics, over 5,000 employees lost their lives in work-related accidents in the US last year. One of the most common reasons for these accidents is the improper handling of materials. Continue reading “Things You Need To Know About Oversize Load Transportation”

Four Tips About Material Handling Equipment: How To Use Them Properly

Efficiency is the key to improving profitability no matter what industry you operate in. The more efficient a company’s processes are, the higher the revenues it can generate. But if the company continues losing money due to inefficient processes, the risk of eventually going out of business increases significantly. Continue reading “Four Tips About Material Handling Equipment: How To Use Them Properly”

Surprising Facts About Material Handling Equipment

Material handling might not sound like it, but it’s a fascinating process that impacts the storage, transportation, operation, safety, and distribution procedures in different industries. Continue reading “Surprising Facts About Material Handling Equipment”

Pneumatic Casters For Moving Warehouse Equipment: Five Advantages

Moving heavy loads – equipment, products, and more—is inevitable in warehouses and other industrial spaces. With electrical equipment moving systems exhibiting limitations in certain environments, many warehouse owners are considering replacing conventional equipment moving solutions with air-based ergonomic equipment. Continue reading “Pneumatic Casters For Moving Warehouse Equipment: Five Advantages”

Heavy Equipment Moving Made Easy With Air Skates: A Brief Guide

Businesses in diverse sectors worldwide depend on pneumatic heavy load moving solutions like the ones offered at Hovair Systems to move equipment and other objects on a thin film of compressed air. Also known as air dollies, machine skates, and air bearing modules, machine skates utilize air film technology to move loads safely, easily, and cost-effectively. Continue reading “Heavy Equipment Moving Made Easy With Air Skates: A Brief Guide”

The Top Four FAQs About Compressed Air

Are you considering investing in air-based heavy load moving solutions by Hovair Systems to make operations smoother, quicker, and safer? You’ll also need a high-functioning compressor that ensures an adequate and consistent air supply. We’ve got you covered for compressors and tools you need to bolster your outdated solutions. Continue reading “The Top Four FAQs About Compressed Air”

Tips For Selecting the Right Vehicle Turntable

Unfortunately, buying a larger home or office when you need more room isn’t easy, especially when a toxic mix of recession risks hangs over the global economy. One favored way to expand the existing restricted space is to utilize the garage properly. Turntables are the perfect solution for those looking to use smaller spaces more efficiently. Continue reading “Tips For Selecting the Right Vehicle Turntable”

Key Components For A Fully Optimized Food Distribution Warehouse

The food distribution warehouse is a prime example of a sector of the economy where the warehousing process is intricate. There are a lot of guidelines and regulations, but it’s all for a good cause: making the distribution system safer and more efficient for everyone involved. Continue reading “Key Components For A Fully Optimized Food Distribution Warehouse”

How Warehouse Storage Has Evolved: How To Stay Up-To-Date

The emergence of third-party logistics (3PL) and eCommerce industries has transformed the landscape of warehouses. These facilities have gone from simple storage spaces to fully operational facilities. Continue reading “How Warehouse Storage Has Evolved: How To Stay Up-To-Date”

Foolproof Ways To Futureproof the Material Handling Systems in Your Facility

While no one can accurately predict the future, it’s possible to futureproof the material handling systems to adapt them to new industry developments and modern technologies. Continue reading “Foolproof Ways To Futureproof the Material Handling Systems in Your Facility”

Everything You Need To Know About Semi-Automated Material Handling Systems

Semi-automated material handling systems are gaining popularity as an incredible alternative to fully automated warehouses. These systems are integral to operating efficiently and gaining an edge over the competition without needing to invest hefty amounts in fully automated systems. But what exactly do semi-automated material handling systems include and what are the key benefits? Let’s find out! Continue reading “Everything You Need To Know About Semi-Automated Material Handling Systems”

Using Automation to Improve Bulk Material Handling Efficiency

Manufacturers worldwide are under constant pressure to produce goods more quickly, at a lower cost, without compromising quality. Technology has made it possible to optimize processes using the right automated tools. The first mile of automation involves how raw materials are received, transported, and stored from the moment they enter the manufacturing plant. Continue reading “Using Automation to Improve Bulk Material Handling Efficiency”

List of Warehouse Material Handling Equipment Used For Cargo

Vehicles, tools, and storage systems of all kinds fall under the umbrella of “material handling equipment” (MHE). The typical function of a warehouse is to temporarily stock materials before transporting them to their final destination. Warehouse efficiency increases as the ease of transporting goods improves. Having the proper materials for the job will enhance productivity by reducing the amount of unnecessary stress and physical labor your employees must endure. Continue reading “List of Warehouse Material Handling Equipment Used For Cargo”

Material Handling Solutions in Heavy Duty Areas

Heavy duty areas in facilities face diverse challenges that include processing, storing, and moving difficult-to-handle material. Downtimes can be cost-intensive; therefore, it’s essential to work with specialists to help you choose suitable material handling solutions for your facility. Safety, reliability, and efficiency are necessary for your business’s bottom line, and Hovair’s ergonomic equipment offers it all. Continue reading “Material Handling Solutions in Heavy Duty Areas”

Material Handling Trends You Need To Be Aware of in 2022

Technological advancements have led to the world evolving at a rapid pace. The material handling industry is no different, with innovative developments and processes altering how the sector functions regularly. Continue reading “Material Handling Trends You Need To Be Aware of in 2022”

Why Material Handling Equipment Is Important To Your Operation

Material handling is the art and science of receiving, packing, moving, or storing material in any form. It directly impacts productivity in manufacturing plants, warehouses, and distribution centers. Continue reading “Why Material Handling Equipment Is Important To Your Operation”

What Are AGVs?

Automated Guided Vehicles (AGV) are self-driving solutions widely used in different industries for diverse material handling applications. The high-quality navigation system follows a specific route or path to transport materials independently. It’s incredibly useful in large warehouses or industrial spaces involving consistent and repetitive movements. AGVs have helped managers in many sectors improve safety protection and autonomous efficiency of heavy loads moving, leading to long-term operational and higher ROI benefits. Continue reading “What Are AGVs?”

How To Choose A Material Handling Solutions Provider

Selecting the right material handling equipment provider can be overwhelming for some business owners. You might find yourself wading through a wide range of products only to feel more confused about the best course of action for your facility. Continue reading “How To Choose A Material Handling Solutions Provider”

Top Four Reasons Manual Wheel Casters Fail: How To Avoid The Nuisance

While casters may be a small part of the grand design of material handling equipment, they play an integral role in the cart’s safety and efficiency. While the caster technology may have experienced evolutionary changes in the last few decades, wheel casters still come with many complex challenges that can impact the company’s bottom line. Continue reading “Top Four Reasons Manual Wheel Casters Fail: How To Avoid The Nuisance”

Things To Consider Before Purchasing Material Handling Equipment

Heavy load handling is an integral part of every industry that requires materials to be moved or stored between locations. Reliable material handling equipment ensures faster, safer, and more efficient movement of loads through a range of processes, from manufacturing to storage, distribution, and delivery. Continue reading “Things To Consider Before Purchasing Material Handling Equipment”

Paper Roll Handling: Is Automation Right for Your Facility?

With the potential to improve worker safety, productivity, and the bottom line, paper roll handling technology is making its way into several operations. Converters are recognizing that, with automation, paper rolls can be handled at larger volumes efficiently and safely more accurately, quickly, and cost-effectively. Continue reading “Paper Roll Handling: Is Automation Right for Your Facility?”

Mega Moving Management: The Main Steps of Super-Heavy Hauling

The Energy Department’s Super Truck initiative has enabled the efficient transportation of super-heavy loads across state lines and reduced the dependence on air freight to haul extra-large objects, saving the supply chain millions of dollars worth of fuel and time. Continue reading “Mega Moving Management: The Main Steps of Super-Heavy Hauling”

Tips You Should Know About Air Tools

Unplanned downtime costs manufacturers almost $1 trillion every year. Due to subpar care, even the finest air-bearing products are bound to fail before their best-by date. Prematurely replacing an air tool doesn’t just cost money, but the void it leaves also affects your bottom line. Continue reading “Tips You Should Know About Air Tools”

Safety Precautions When Using Lifting Equipment

Texas tops the chart for most crane-related fatalities at the job site. Most of these fatal injuries are struck-by incidents caused by improper use of material handling equipment. Training for heavy load handling systems exists for a reason: to keep the users and their surroundings safe from damage and injury. Continue reading “Safety Precautions When Using Lifting Equipment”

Automated Warehouse Logistics: Plan for Supportive Material Handling Equipment

With warehouse demand skyrocketing in several US states, it’s only a matter of time before yours runs out of space. More warehouses are narrowing their aisles and embracing automated guided vehicle systems and material handling equipment to ensure safe and efficient storage and inventory management. Continue reading “Automated Warehouse Logistics: Plan for Supportive Material Handling Equipment”

Main Advantages Of Pneumatic Systems In Comparison To Electric

Unlike conventional electric or hydraulic powered tools, pneumatic tools operate using compressed air. These tools are attached to air compressors or motors that force air continually to ensure constant pressure when moving heavy loads. Continue reading “Main Advantages Of Pneumatic Systems In Comparison To Electric”

Factors To Consider When Choosing Lifting Gear

Lifting and rigging equipment is required in many applications. Recommended in safe lifting manuals, it dramatically reduces instances of workplace injuries and fatalities. However, selecting the wrong equipment is just as bad, if not more so, as not having any heavy load moving machinery. Continue reading “Factors To Consider When Choosing Lifting Gear”

Top Warehouse Loading Dock Safety Tips

As the manager, you’re responsible for creating a safe work environment, especially when the environment in question is a congested loading dock filled with heavy loads and obstructions that make it easier for workers to sustain injuries. You may not see them as a big deal, but they cost the supply chain $675 million annually. Continue reading “Top Warehouse Loading Dock Safety Tips”

Using Skates for Moving Heavy Objects

You’ll find plenty of ergonomic equipment moving systems at Hovair Systems suitable for different shapes, sizes, dimensions, and weights. Skates are a recurring feature in our material handling equipment. They prevent the hazards of manual handling and make operations much easier across various sectors. Continue reading “Using Skates for Moving Heavy Objects”

Tools That Make Moving Heavy Equipment Easier

Office equipment, furniture, appliances, machinery parts… different businesses may need to move diverse heavy items every day. Most of these items pose various unique logistics issues when it’s time to move, load, and unload. Continue reading “Tools That Make Moving Heavy Equipment Easier”

Common Supply Chain Issues That Could Delay Equipment Delivery

Supply chain disruption is any firm’s worst nightmare. The impact of supply chain disruptions on companies can range from minimal to severe. A minor disruption may lead to an item being out of stock for a relatively brief period while large delays can result in a significant loss of sales and revenue. In the worst-case scenario, a customer might decide to cancel the contract altogether because of their losses and switch to your competitor. Learn about the common issues that can cause supply chain issues for your firm and how air caster material handling solutions can help.

Production Delays

Delay in the manufacturing process can be due to a failure of machinery or the unavailability of materials. Other factors include severe weather or labor going on strike. A human error can also cause bottlenecks to emerge in one stage which may cause a problem for another part of the production line. This creates a ripple effect on scheduled deliveries. Manufacturing delays can also be caused by poor planning, and over-committing to a client when the processing capabilities are simply not there at the plant. Similarly, if key employees are unable to return to work due to an injury, this too could delay the delivery process.

Warehousing Delays

Another reason for the delay in dispatching orders can be slow processing at the warehouse. The equipment can be really heavy and staff might still be using outdated methods to move items from one location to the other. This is why it’s important to upgrade to better methods like using air beams, lift decks, and lifting jacks. This will also reduce the chances of your staff getting injured.

Shipping Delays

Issues with loading or unloading of goods onto carriers or ships can also cause delays. Make sure you work with a shipping provider that uses state-of-the-art tools to move equipment so that they can load the items on their ship faster and in a secure manner.

Also, make sure you have a tracking number for any package shipped from a warehouse. This way, if there are delays due to weather conditions, you’ll be able to monitor its progress online so that you know when it will arrive at its destination.

Affordable Air Caster Material Handling Solutions

At Hovair Systems, we provide high-quality material handling equipment that helps you minimize issues that can cause supply chain disruptions. Our state-of-the-art air-bearing kits, lifting jacks, air pallets, and air compressors help you move equipment fast so that you always deliver to your clients on time. We don’t compromise on quality which is why our portfolio of clients includes the likes of Hewlett-Packard, Lockheed Martin, Goodrich Aerospace, Boeing, Pilkington, and Siemens, among others.

Reach out to us today for more details. Get a free quote here.

Optimizing Retail Inventory Levels: The Role of Material Handling Equipment

Matching inventories to the ever-evolving demands is always an enormous challenge for retailers worldwide. Too little, and they miss out on the make-or-break opportunities. Too much, and they may hemorrhage their hard-earned savings in handling or storage costs. Either way, retail operators will have to deal with higher costs and lost revenues. Continue reading “Optimizing Retail Inventory Levels: The Role of Material Handling Equipment”

How to Ensure Safety While Using Rigging Equipment

Rigging equipment helps businesses lift loads and maneuver them for use or storage safely. They can be dangerous when used incorrectly. When rigging equipment is used, safety must be taken into consideration at each step in the process. As the manager, you are responsible for the safety of your workforce. Failure to do so could lead to nasty injuries, a lawsuit, and even someone losing their life. You must make sure that the right protocols are followed when using rigging equipment at your workplace. Continue reading “How to Ensure Safety While Using Rigging Equipment”

The Most Important Ergonomics Tips for Warehouse Workers

Ergonomics is a very important aspect of any industry, but it’s especially critical in warehouses. The warehouse environment can be very harsh on the body with all of the bending, reaching, carrying heavy items, and repetitive motions that are required daily. Implementing these ideas into your workplace, including using technologies such as air lifting bags, can help reduce the risk of injury within your workforce. Continue reading “The Most Important Ergonomics Tips for Warehouse Workers”

How To Avoid Extra Costs When Shipping Heavy Loads

We must not underestimate the need for regularly reviewing heavy equipment moving methods. Technology advances frequently, new strategies come up, and costs can rise due to several factors. Frequently analyzing shipping and load moving methods is a great way to get the most value for your investments. Continue reading “How To Avoid Extra Costs When Shipping Heavy Loads”

Root Cause Analysis: Reducing Material Loss In Manufacturing

Recognizing the problem is a key step in adapting effective and efficient manufacturing practices. Organizations must consistently look for inefficiencies that impact the throughput. Continue reading “Root Cause Analysis: Reducing Material Loss In Manufacturing”

The Possible Applications of Air Bearing Systems

Material handling equipment is something that many industries won’t be able to function without. The market is projected to grow at a CAGR of 5.5% from 2021 to 2028. The air bearing is preferred over mechanical bearings for its many benefits and because its use isn’t limited to a handful of industries. It decreases the cost with its precision and can be used in industrial equipment, manufacturing process, etc. Some possible applications are given below: Continue reading “The Possible Applications of Air Bearing Systems”

Heavy Equipment That’s Worth The Investment: Should You Buy Or Rent?

Heavy equipment is used in nearly every industry that deals with manufacturing and moving heavy loads. Globally the heavy equipment industry is valued at $176.2 billion in 2020 and is expected to double by 2030. This includes both the rental of heavy equipment and its purchase. But which one is right for the industry? Well, it depends on several factors. Here’s how you can decide. Continue reading “Heavy Equipment That’s Worth The Investment: Should You Buy Or Rent?”

Top-Notch Ways To Get Your Dollars’ Worth When Investing in Material Handling Equipment

Hovair Systems wants you to reap tremendous rewards and get your money’s worth when purchasing material handling equipment for your faculty. Our deep understanding of how large weights function and move and cost-effective rates have made us recognized as one of the leading platforms that design and build moving solutions for large and small-scale industries. Continue reading “Top-Notch Ways To Get Your Dollars’ Worth When Investing in Material Handling Equipment”

Types Of Material Handling Equipment For Warehouses

Material handling equipment refers to the tools used to aid the movement, storage, protection, and control of products or materials.

Without proper systems and equipment in place, products are likely to end up being damaged in your warehouse. Inefficient equipment could also lead to a dip in overall productivity levels. How to decide what equipment will enhance functionality and efficiency in your faculty? Continue reading “Types Of Material Handling Equipment For Warehouses”

Top Tips for Material Handling Injuries Prevention

Ergonomic hazards could put employees at risk, negatively impacting the business as a whole. Repetitive motions, poor posture, extreme temperatures, excessive weight, and improper lighting are some of the most common hazards that can lead to MSDs and injuries. Continue reading “Top Tips for Material Handling Injuries Prevention”

How Do Air Lifting Bags Work?

Air lifting bags utilize compressed air to lift gigantic and heavy loads conveniently. They’re used in various applications because of their ease of deployment and lightness. The slim profile and ability to disperse loads evenly make them more beneficial than traditional tools used to move loads. Continue reading “How Do Air Lifting Bags Work?”

How to Safely Load and Transport Heavy Equipment: A Brief Guide

Transportation of heavy equipment is no easy task, especially if you’re not used to it. According to the US Bureau of Labor’s statistics, there are around 400 deaths from heavy equipment accidents. While handling these massive pieces, having a guide on hand to load, transport, and unload is the way to go. Below is a brief guide to help get started with loading and heavy equipment moving. Continue reading “How to Safely Load and Transport Heavy Equipment: A Brief Guide”

Top Reasons Turntables Have Become an Essential Part of Modern Garages

There’s nothing as frustrating as parking your car in a small garage space or a narrow driveway. Even after several crazy maneuvers for exiting or parking the car safely, the chances of your car being damaged are high. Continue reading “Top Reasons Turntables Have Become an Essential Part of Modern Garages”

Understanding The Need For Ergonomic Equipment

Workers often experience increased stress because of their work setting. This negatively impacts their psychological health and performance. Workplace stress can be caused by various factors, including workplace ergonomics.

Continue reading “Understanding The Need For Ergonomic Equipment”

Continue reading “Understanding The Need For Ergonomic Equipment”

Lifting and Material Handling – Health & Safety Issues

As per a study undertaken by the US Department of Labor, 5,333 tragic work-related injuries were reported in 2019. Although there are numerous hazards to workers’ occupational health, improper weight lifting and moving is one of the most common reasons for industrial fatalities.

Continue reading “Lifting and Material Handling – Health & Safety Issues”

Continue reading “Lifting and Material Handling – Health & Safety Issues”

Different types of Automated Guided Vehicles and their Usage

Manual material carrying is an antiquated paradigm in today’s world. In corporate sectors, Automated Guided Vehicles are now employed to transfer loads from one location to the other.

Continue reading “Different types of Automated Guided Vehicles and their Usage”

Continue reading “Different types of Automated Guided Vehicles and their Usage”

Air Casters: What They And How They Are Used

The practice of hoisting heavy objects dates back to the construction of Egyptian pyramids when men painstakingly carried large slabs and stones. Throughout that time, the death rate was alarmingly high, and workers were at risk of developing physical disabilities. Even in this day of innovation and automation, manual handling still puts people at the risk of fatalities.

Continue reading “Air Casters: What They And How They Are Used”

Continue reading “Air Casters: What They And How They Are Used”

Important Rigging Safety Guidelines You Need to Know

When it comes to setting the best standards and rules of procedures for construction equipment workers in the United States, OSHA is extremely rigid. To assist workers in limiting the risk of occupational injuries, the association has proposed various laws and guidelines, educational manuals, and to-do checklists.

Continue reading “Important Rigging Safety Guidelines You Need to Know”

Continue reading “Important Rigging Safety Guidelines You Need to Know”

Various Tools that Make Moving Heavy Machinery Simple

Personnel’s well-being must always be a priority when it comes to workspaces. As per the Bureau of Labor Statistics of the US Department Of labor, 5,190 full-time employees suffered from tragic work-related accidents. Although there are numerous hazards to workers’ wellness workplace, improper material loading and moving is likely one of the most common reasons for occupational mishaps.

Continue reading “Various Tools that Make Moving Heavy Machinery Simple”

Continue reading “Various Tools that Make Moving Heavy Machinery Simple”

How To Avoid Mishaps With Material Handling Equipment

Carrying objects manually, according to OSHA studies, causes a variety of safety problems and also poor occupational ergonomics. Because of the significant link between ergonomic difficulties and misallocation of resources, industrial companies are taking initiatives to make their workplaces as secure and convenient as possible for their workers.

Continue reading “How To Avoid Mishaps With Material Handling Equipment”

Continue reading “How To Avoid Mishaps With Material Handling Equipment”

Understanding The Importance Of Air Lifting Bags

In the heavy-lifting industry, airlifting bags have earned a name for themselves. They’re used in a variety of sectors, including the automobile sector. Due to the use of high-quality materials and craftsmanship, as well as strict quality control, the bags are safer to use. At varying compressed air levels, they can lift massive amounts of weight.

Continue reading “Understanding The Importance Of Air Lifting Bags”

7 Benefits Of Using Compressed Air Tools

The origins of cargo hoisting can be traced back to the Egyptian Pyramids, when employees manually carried huge burdens. Countless people died and were injured throughout that period. Nevertheless, there are a huge proportion of occupational fatalities caused by conventional load handling in today’s technological age. The usage of pneumatic hoisting gear is a cost-effective way for businesses to minimize workplace injuries and increase output.

All You Need to Know About Air Lifting Bags

Air lifting bags have made their mark on the heavy loading industry. They are being used in different industries like the automotive industry. The bags are safer to use thanks to the utilization of high-quality resources, workmanship, and stringent quality monitoring. They can hoist tons of weight at various pressurized air levels.

Continue reading “All You Need to Know About Air Lifting Bags”

Power Generation Applications of Hovair Products

Energy consumption rises with industrial prosperity, demographic, and infrastructural facilities. A cost-effective and efficient power source is more important than before.

Continue reading “Power Generation Applications of Hovair Products”

Remote Control Units & Their Importance

Remote control technology is benefiting every industry known to human beings. Manufacturing processes can be controlled remotely, allowing for fast solutions to any technical or structural issues with machinery, even if they are located in separate facilities.

Shipyard Industry and Applications of Air Bearings In It

The American boatbuilding sector has a long history back to the American Revolution. The USA has three long shorelines and also multiple docks and waterways where shipbuilding enterprises have operated for over two hundred years.

Continue reading “Shipyard Industry and Applications of Air Bearings In It”

Lift Decks – What Are They & How to Buy Them

Lift deck motorized steered vehicles carry items to and from platforms and are perfect for carrying stacks and trolleys. These machines can transport a variety of packages and offer maximum versatility. Lift decks are fitted with weight topping sensing devices that can properly position cargoes irrespective of container dimensions. Furthermore, their adjustable lift elevation enables them to be tailored to your exact requirements.

Continue reading “Lift Decks – What Are They & How to Buy Them”

How to Choose the Best Air Pallets for Material Handling

Material handling is a crucial aspect of any business, and if you wish to thrive in the industry, you need to plan for it. Moving and lifting products from one point to another is not as simple as one might think and can lead to severe consequences. If the product flow is not better, then the whole system can get compromised. It’s essential to opt for the right equipment for your warehouse or any other industry to maximize profit on each product.

Material handling is a crucial aspect of any business, and if you wish to thrive in the industry, you need to plan for it. Moving and lifting products from one point to another is not as simple as one might think and can lead to severe consequences. If the product flow is not better, then the whole system can get compromised. It’s essential to opt for the right equipment for your warehouse or any other industry to maximize profit on each product.

Continue reading “How to Choose the Best Air Pallets for Material Handling”

How Can Hovair Benefit from Mass Transit Applications

Private transportation is popular because it’s often administered on a timetable, operated on known itineraries, and charges a posted price for each journey. Similarly, public transportation provides transportation network for travelers through collective commute methods accessible to a wider audience.

Private transportation is popular because it’s often administered on a timetable, operated on known itineraries, and charges a posted price for each journey. Similarly, public transportation provides transportation network for travelers through collective commute methods accessible to a wider audience.

Now, the question is, how can leading companies like Hovair benefit from mass transit applications?

Continue reading “How Can Hovair Benefit from Mass Transit Applications”

Air Bearings & Its Applications in the Entertainment Industry

To execute high-speed operations without precession problems, the vast majority of businesses now use air bearings rather than traditional metal contact bearings. A wide range of bearings available on the market is ineffective at reducing friction. Roller bearings, for example, frequently cause contact between the surfaces during operation, resulting in heat generation and machine wear and tear.

Continue reading “Air Bearings & Its Applications in the Entertainment Industry”

Types of AGVs (Automatic Guided Vehicles)

If you visit an advanced warehouse or construction site, you’ll see a wide range of vehicles traveling and moving around autonomously without a driver or an operator. These are referred to as automatic guided vehicles or AGVs, also known in many industries as self-guided vehicles.

If you visit an advanced warehouse or construction site, you’ll see a wide range of vehicles traveling and moving around autonomously without a driver or an operator. These are referred to as automatic guided vehicles or AGVs, also known in many industries as self-guided vehicles.

These are some of the most advanced material handling equipment found in industries these days. If you’re wondering what they do and how they work, here are three different AGV types to help you understand.

Automated Guided Carts

If there’s one basic AGV consisting of all the primary AGV features that all the other AGV types have, it’s the automated guided carts. Also known as AGCs, these are the most popular kinds of automated guided vehicles with various navigation systems depending on their industrial applications.

These include complex navigation systems, magnetic tape systems, sensor-based systems, and more. Apart from being used to transport smaller loads, AGCs also come in handy for industries involved in storing and compartmentalizing loads.

Forklift AGVs

Another most popular type of automated guided vehicle is a forklift AGV. These are high-quality vehicles used for transporting materials from one location to another to store them safely.

These vehicles operate the same way as human-operated forklifts. However, the only difference is that forklift AGVs work through an automated mechanism without the need for a human operator.

Heavy Burden Carriers

If there’s one type of AGV that’s relied upon to carry and haul the heaviest loads, it’s the heavy burden carriers. These carriers are a unique type of AGV with extensive applications in industries requiring large assemblies.

These carriers are automated. Therefore, they can self-load materials through their pivot steering features.

Now that you know what AGVs are, how they operate, and how they’re different from the rest of their types, you may be looking for the best ways to handle these vehicles efficiently. It’s always a good idea to resort to a company known for manufacturing the right material handling equipment for this purpose.

Now that you know what AGVs are, how they operate, and how they’re different from the rest of their types, you may be looking for the best ways to handle these vehicles efficiently. It’s always a good idea to resort to a company known for manufacturing the right material handling equipment for this purpose.

At Hovair Systems, we’re known for our extensive experience and commitment towards providing every industry with high-quality heavy load handling systems and ergonomic equipment moving systems. You can now rely on us to find multiple products, including load leveling airbags, airlifting bags, car turntables, air skates, air pallets, air skids, and more. Check out our products here or contact us to learn more today!

Air Lifting Tools vs. Electric Tools | What’s the Best Choice for Manufacturers?

Tools are an essential part of the manufacturing industry. However, a project’s success depends on the kinds of tools you choose for each task. Airlifting and electric tools are the most common during these practices. Here’s a quick comparison between both to help you pick the right one.

Tools are an essential part of the manufacturing industry. However, a project’s success depends on the kinds of tools you choose for each task. Airlifting and electric tools are the most common during these practices. Here’s a quick comparison between both to help you pick the right one.

Punch

The first thing to keep in mind when determining which kind of tool is the best for the manufacturers is the strength each tool possesses. In other words, it’s crucial to understand the mechanisms of both airlifting and electric tools before choosing between the two.

A tool’s punch refers to the process it employs to complete the job. Airlifting or pneumatic tools are stronger and more adjustable than electric tools. Despite the benefits of cordless tools among electric devices, airlifting tools remain superior due to their adjustable punch.

Costs

The costs are a significant cause for concern among manufacturers who don’t want their money to go to waste. Therefore, it’s crucial to think about the long-term costs of both pneumatic and electric tools.

If you choose to invest in airlifting tools, you may have to bear higher upfront costs. However, the backend costs of these tools are significantly lower. Similarly, electric tools might be affordable to purchase, but their frequent maintenance and need for replacement may result in higher costs.

Weight

Lastly, it’s crucial to think about the feel of each tool to determine its usability. For instance, if you choose to work with airlifting tool, you’ll notice how it’s lighter and easier to work with for a longer time.

Similarly, electric tools are relatively heavier but can also benefit some users by being cordless. Choosing between both kinds of tools depends on the duration of their usage.

Airlifting tools offer a lot more benefits and ease for manufacturing companies than electric power tools. However, choosing the right company that specializes in manufacturing material handling equipment is critical if you want to make the most out of airlifting tools for your company. You can now get started by checking out the heavy machinery lifting equipment offered by us at Hovair Systems.

Airlifting tools offer a lot more benefits and ease for manufacturing companies than electric power tools. However, choosing the right company that specializes in manufacturing material handling equipment is critical if you want to make the most out of airlifting tools for your company. You can now get started by checking out the heavy machinery lifting equipment offered by us at Hovair Systems.

With over 50 years of experience and knowledge, we know what a company needs. Therefore, we continue to offer the best heavy load handling systems and ergonomic equipment moving systems. Some of our most sought-after products include load leveling airbags, airlifting bags, car turntables, air skates, air pallets, air skids, and more. Check out our products here or contact us to learn more today!

A Guide to Choosing the Right Material Handling Equipment for Your Business

Material handling equipment has now become an integral part of a wide range of industries today. However, increased demands for this equipment have made it challenging for businesses to pick the devices that suit their needs. Here are three factors to always keep in mind when choosing the right material handling equipment.

Material handling equipment has now become an integral part of a wide range of industries today. However, increased demands for this equipment have made it challenging for businesses to pick the devices that suit their needs. Here are three factors to always keep in mind when choosing the right material handling equipment.

Think About the Materials

The first thing you should think about when trying to choose the right material handling equipment for your business is the kind or type of materials you’re operating with. This is the primary consideration that ultimately determines what material handling equipment will fit your requirements.

Wooden and textile-based materials have different requirements, while chemical materials are handled differently. Furthermore, their packaging and processing also play a critical role in determining what material handling equipment works the best for you.

Keep the Space in Mind

The next key factor to keep in mind is the space or location available to you to use the material handling equipment. You should assess your space for operating heavy equipment and choose the material handling devices accordingly.

It’s always better to choose equipment that saves space to prevent accidents, collisions, and other heavy equipment hazards.

Focus on Affordability

Lastly, it’s always good to think about the costs when you’re trying to pick the right material handling equipment. A good rule of thumb to follow is to set a budget beforehand and browse through equipment within the decided price range.

This will help you shortlist the equipment you need and the steps to take to make the best use of it.

Now that you know all the ABCs of finding, choosing, and working with the right material handling equipment that meets your requirements effortlessly, you may be looking for a company that can help you meet this goal. An excellent way to get your hands on the right material handling equipment is by choosing a company that specializes in encouraging the automated handling of heavy loads by manufacturing high-quality heavy machinery lifting equipment.

Now that you know all the ABCs of finding, choosing, and working with the right material handling equipment that meets your requirements effortlessly, you may be looking for a company that can help you meet this goal. An excellent way to get your hands on the right material handling equipment is by choosing a company that specializes in encouraging the automated handling of heavy loads by manufacturing high-quality heavy machinery lifting equipment.

You can now count on ou professionals at Hovair Systems for e everything you need when it comes to employing the right heavy load handling systems and ergonomic equipment moving systems. We offer a wide range of products, including load leveling airbags, airlifting bags, car turntables, air skates, air pallets, air skids, and more. Check out our products here or contact us to learn more today!

3 Common Heavy Equipment Accidents

The US Occupational Safety and Health Administration (OSHA) states that the leading causes of fatal injuries and deaths in the construction industry are accidents resulting from heavy equipment accidents. If you’re wondering what these are and why they happen, here are three common heavy equipment accidents you should know about.

Smart Handling of Heavy Equipment | A Brief Guide

Handling heavy equipment can be a challenging process, especially if your first priority is to ensure maximum safety and the prevention of accidents at all times. If you’re affiliated with an industry that requires you to work with heavy equipment, here are some tips you should keep in mind.

Handling heavy equipment can be a challenging process, especially if your first priority is to ensure maximum safety and the prevention of accidents at all times. If you’re affiliated with an industry that requires you to work with heavy equipment, here are some tips you should keep in mind.

Continue reading “Smart Handling of Heavy Equipment | A Brief Guide”

Rigging Equipment | Everything You Should Know

As industrial needs continue to become more and more complex, they need to upgrade their rigging systems. Today, manual handling or roller bearings and other means of material handling have become outdated. The primary reason why now more than ever, companies are considering investing in air-powered rigging systems is that it’s not cost-effective, but also a safe and secure method that ensures environmental safety and your employees’ health while also helping them improve their industrial productivity.

As industrial needs continue to become more and more complex, they need to upgrade their rigging systems. Today, manual handling or roller bearings and other means of material handling have become outdated. The primary reason why now more than ever, companies are considering investing in air-powered rigging systems is that it’s not cost-effective, but also a safe and secure method that ensures environmental safety and your employees’ health while also helping them improve their industrial productivity.

A company’s success and profitability heavily rely on its rigging systems. If a company uses traditional means for transportation and lifting of their products, goods, and machines from one point to another, a majority of their worker’s time and energy gets wasted. Their industrial processes become slower, and the overall industrial outputs start lacking behind that of their competitors.

Continue reading “Rigging Equipment | Everything You Should Know”