Have you ever considered deploying flexible material handling solutions in your industrial space? This sort of equipment is used by all kinds of companies to move heavy loads as efficiently and safely as possible. It helps everyone from mass transit manufacturers seeking ways to efficiently move train parts during maintenance to power generation experts who want to lift solar panels into position at their clients’ premises.

In this article, we look at how some of the most commonly used material-handling equipment help companies minimize operational costs and maximize workplace safety. Without further ado, let’s jump in!

Minimizing Operational Costs

Using Air Pallets to Move Heavy Loads Quickly

How it Works

How it Works

Air pallets use leverage to lift and move heavy loads in the same way as traditional pallet trucks. The key difference is where that leverage comes from—pallet trucks use a crank that must be pumped up and down by hand, while air pallets harness the power of air compression.

Compressed air is pushed out of the air pallet at a greater pressure than the weight of the load. This eliminates friction because a tiny layer of air forms between the load and the pallet surface. As a result, the object can be moved using a fraction of the force required to move it using a regular pallet truck.

Effect On Operational Costs

Air pallets reduce the force needed to move heavy loads around an industrial space. Therefore, the time taken to move multiple loads is lower than spaces that utilize traditional pallet trucks. The time it takes to move a load has an inverse relationship with the number of loads that can be moved in one working day.

For instance, suppose a factory’s overheads amount to $50,000 per month. One factory worker can move 100 loads weight 50kg each in a day using traditional pallet trucks—but if they switch to an air pallet, they’ll be able to move 160 loads weighing 50kg each (because the force required to move one load will be lower). In this scenario, the overhead cost per load unit is $500 for traditional pallet trucks but just $312.50 for air pallets!

Accurately Rotating Heavy Loads into Position On Computerized Industrial Turntables

How it Works

How it Works

As the name suggests, industrial turntables rotate heavy objects to the desired position using compressed air or electro-mechanical power. They’re typically used in tandem with rigging equipment to maneuver heavy parts like jet engines and spacecraft fuselage parts into position before they’re bolted together.

Industrial turntablesthat rely oncompressed air feature platforms with air bearings that lift heavy objects. Once the object is floated on the platform, the lack of friction makes it easy to rotate it on a central axis.

Effect On Operational Costs

The ideal way to understand the effects of industrial turntables on operational costs is to look at how else a heavy load may be rotated.

One of the main alternatives to using an industrial turntable is to lift the load using pulleys, ropes, and hooks (traditional rigging/hoisting equipment)before turning it to the desired orientation. This takes a long time because workers must secure the load to keep the center of gravity in an appropriate position so the rope doesn’t snap during transport. The longer this process is, the more energy is used to keep the object hoisted before it is rotated.

In contrast, if you’re using industrial turntables, all you’ve got to do is place them underneath the object, and the air compressor does the work for you. This results in the object being rotated quicker, and the energy used is lower—so operational costs are lower too.

Eliminating Transportation Instability Through Load-Leveling Airbags

How it Works

How it Works

Load-leveling airbags are designed to be sandwiched between heavy loads and the floor. Air is subsequently pumped into the bags, causing them to inflate and lift the load off the ground. Load-leveling airbags are designed to allow operators to lift loads at precise angles.

For instance, suppose the optimal way to move an object is to keep it tilted because it’s heavier on one side. In this scenario, you can lift the load higher off the ground on one side compared to the other by pumping the appropriate amount of air into airbags placed on either side of the object.

Effect On Operational Costs

Load-leveling airbags are a cheaper way to lift and transport unevenly weighted loads compared to alternatives like rigging equipment because they require less power/force due to energy-efficient air compressors. They also provide cushioning to keep heavy loads stable during transportation and avoid workers from injuring themselves. As a result, operational costs are saved because there’s a lower chance of paying workplace injury compensation. Moreover, floor spaces are less likely to be damaged during the transportation process.

Move Multiple Large Loads Simultaneously Using Air-Powered Rigging Equipment

How it Works

How it Works

Air-powered rigging equipment consists of a complete system with numerous air beams, bags,pallets, and compressors connected to move multiple heavy loads smoothly. The idea’s simple—several air bags and beams are placed at various points underneath the objects to raise them a few inches off the ground. This is achieved by pumping compressed air at high pressure into the bags and through tiny holes in the beams. Once the objects are raised, air pallets are placed underneath to keep them all afloat. Workers can then move the objects at the same time to the desired location in the industrial space.

Effect On Operational Costs

Air-powered rigging equipment reduces operational costs by streamlining the assembly process and ensuring multiple components come together simultaneously to minimize damage.

For example, if you’re assembling a plane, you must attach the forward engine mount, aft engine mount, aft wing/pylon, and fwd wing/pylon simultaneously using bolts in a meticulously balanced manner. If this isn’t done properly, the parts can come undone and/or break. This will cost you a hefty sum for replacements—not to mention potential contract cancellations from failing to fulfill orders on time.

Air-powered rigging equipment allows manufacturers to overcome these issues by maneuvering the right parts into the right positions at the same time before attaching them securely. Moreover, this type of equipment is highly energy-efficient as it uses compressed air rather than fossil fuels.

Put simply, air-powered rigging equipment ensures manufacturers avoid spending excessively on energy and parts maintenance/replacements while speeding up the assembly process.

Maximizing Workplace Safety

Deploying Heavy Duty Transporters

How it Works

How it Works

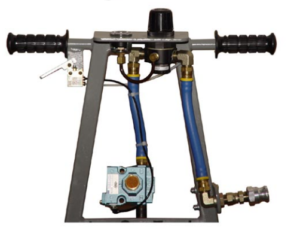

Heavy-duty transporters are essentially large-scale air pallets. They contain a network of air bearings that pump compressed air underneath a platform to lift loads weighing several thousand pounds. Heavy-duty transporters are connected to a remote control that operators can use to activate their pneumatic capabilities.

In simple words, operators can use a remote control to adjust the amount and direction of compressed air pushed out of the transporter’s air bearings to lift loads at various angles and transport them in multiple directions.

Effect on Workplace Safety

Heavy-duty transporters significantly lower the physical strain on employees because they do the heavy lifting on their own. They lift, tilt, and move heavy loads at the push of a button—a stark contrast to traditional rigging equipment that can lift heavy loads but require workers to push and pull the object into position using their own strength.

Heavy-duty transporters also come with several warning alarms and lights to warn workers of their movements. If someone doesn’t see a transporter coming towards them, their safety is assured, thanks to emergency stop bumpers that halt the transporter in place the moment they come into contact with someone.

Controlling Multiple Air Casters Using a Remote-Control Unit

How it Works

How it Works

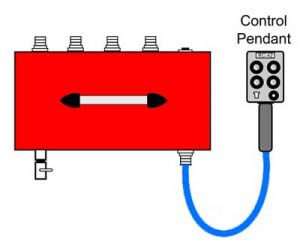

Remote-control units allow operators to control the amount of air being used by several casters at once. They send electrical signals to multiple air casters to adjust the pressure and flow of air coming out of each one.

Remote-control units feature several gauges that show the level of air pressure being pumped through each caster simultaneously. If a heavy object must be tilted or placed in a certain position, the operator can lower the pressure on one or more of the casters accordingly.

Effect on Workplace Safety

The main way remote-control units affect workplace safety pertains to emergency stoppages. For instance, if one of the air beams or casters accidentally slips out from underneath the object, the remaining casters can be stopped immediately using a remote-control unit. As a result, the object can be brought to a halt immediately.

This is far safer than shutting down each caster manually and risking the object going off its intended path/colliding with someone.

Retrofit Heavy Machinery with A-Type Air Bearings

How it Works

How it Works

The diagram above shows the three stages of operation of an A-type air bearing. In the first image on the left, the bearing is deflated around the landing pad in the center. As the bearings are inflated, the landing pad lifts off the ground and a thin film of pressurized air forms around it. Once the bearing is fully inflated, the load floats and is ready to move.

Effect on Workplace Safety

Air bearings may be placed underneath heavy objects and inflated remotely. This is safer than having workers use manual alternatives like jacks to lift the object off the ground. If the heavy load were to collapse on an air bearing, there’d be no risk to workers, provided they’re cleared to a safe distance before the bearings are inflated. In contrast, workers are likely to be close to manual jacks because of how they work—and, therefore, prone to getting injured if it slips.

Using Air Beams to Move Unevenly Weighted Heavy Loads With Minimal Ground Clearance

How it Works

How it Works

Air beams work the same way as air pallets, but there’s one key difference—the former is designed to provide support, while the latter is designed to lift and move heavy loads on its own.

Air beams come in numerous sizes so that they can be placed underneath heavy loads to support them at various points. Each air beam contains a separate valve that allows operators to pump air at various PSI settings depending on whether the object is to be moved, rotated, or tilted.

Effect on Workplace Safety

Air beams minimize the chances of a heavy load collapsing because they support its weight by harnessing the power of compressed air. Workplaces that make use of air beams are safer because there’s a lower chance of loads damaging workstations or collapsing on someone’s foot as they’re being moved around.

Hovair Systems Manufactures and Supplies Flexible Material Handling Solutions to Lower Clients’ Operational Costs and Make Their Premises Safer

Looking for a reliable, ergonomic equipment supplier to provide you with flexible material handling solutions? If so, it’s time to get in touch with our team at Hovair Systems!

We manufacture and deliver some of the highest-quality air pallets, industrial turntables, load-leveling airbags, and air-powered rigging equipment to help companies in various industries lower their operational costs. We also send out heavy-duty transporters, remote control units, air beams, and a-type air bearings that are designed with worker safety in mind.

Contact us now and check out our brochures and product demonstration videos to learn how our equipment can help lower your operational costs and maximize workplace safety.

How it Works

How it Works How it Works

How it Works How it Works

How it Works How it Works

How it Works How it Works

How it Works How it Works

How it Works How it Works

How it Works