In the bustling environment of material handling, workplace safety isn’t just a moral imperative; it’s a fundamental necessity. Every year, millions of workplace injuries in the country lead to both personal suffering and significant financial costs for businesses.

Whether it’s a slip and fall, a strain from lifting heavy objects, or an accident involving machinery, the consequences can be dire.

That’s why at Hovair Systems, we’ve dedicated over five decades to perfecting material handling equipment. Our air-lifting bags, air-bearing modules, and air-bearing turntables offer unparalleled safety, versatility, and efficiency in moving heavy objects, ensuring that your workplace operates smoothly while minimizing the risk of injuries.

In this blog, we’ll delve into essential practices for creating a culture of safety in the workplace, focusing on preventing common injuries and promoting employee well-being. From implementing robust training programs to maintaining equipment and fostering open communication, we’ll explore actionable strategies to safeguard your workforce and enhance productivity.

1. Comprehensive Training Programs:

Thorough training is the cornerstone of a safe workplace. Employees must receive comprehensive instruction on the safe operation of lifting and rigging equipment.

This training should cover not only the technical aspects of operating machinery but also emphasize the importance of following safety protocols and procedures.

Regular refresher courses are essential to reinforce safety protocols and keep employees up-to-date on best practices. Over time, employees may develop bad habits or forget important safety procedures, making refresher courses crucial for maintaining a safe working environment.

These courses can be conducted annually or semi-annually to ensure that safety remains a top priority.

Proper lifting techniques are critical for preventing strains and sprains, which are among the most common workplace injuries. Employees should be trained on the correct way to lift and carry heavy objects, emphasizing the importance of using proper body mechanics and avoiding awkward postures.

By instilling good lifting habits, businesses can significantly reduce the risk of musculoskeletal injuries among their workforce.

Participation in safety seminars and workshops is another valuable component of comprehensive training programs. These events provide employees with opportunities to learn from experts in the field, share best practices, and stay updated on the latest safety regulations and technologies.

2. Regular Equipment Inspections and Maintenance:

Regular inspections of lifting and rigging equipment are essential for identifying any signs of wear or damage that could compromise safety. These inspections should be conducted by trained personnel who can identify potential issues and take corrective action as needed.

Prompt repair or replacement of faulty equipment is crucial for maintaining a safe working environment. If any defects or damage are detected during inspections, they should be addressed promptly to prevent accidents or injuries.

Businesses should have procedures in place for reporting equipment issues and ensure that employees are trained to recognize and report any problems they encounter.

Implementing a maintenance schedule is key to keeping machinery in optimal working condition. Regular maintenance tasks, such as lubrication, calibration, and alignment, should be performed according to manufacturer recommendations.

Training employees to recognize and report equipment issues promptly is essential for maintaining a safe workplace. Employees should be encouraged to report any abnormalities or malfunctions they observe during the course of their work.

3. Ergonomic Design and Workstation Setup:

Investing in ergonomic lifting and rigging equipment is essential for reducing the risk of musculoskeletal injuries. Ergonomic equipment is designed to minimize strain on the body and promote proper body mechanics during lifting and carrying tasks.

Designing workstations with proper lighting, ventilation, and layout is also important for minimizing strain and fatigue. Poorly designed workstations can contribute to discomfort and injury over time, so it’s essential to create environments that promote comfort and productivity.

Businesses should consider factors such as workstation height, chair ergonomics, and access to tools and equipment when designing or modifying workspaces.

Providing adjustable workstations and seating is another way to accommodate different body types and preferences. Not all employees are the same size or have the same physical capabilities, so it’s important to offer options that allow individuals to customize their workstations to suit their needs.

Adjustable desks, chairs, and other furniture can help employees maintain proper posture and reduce the risk of discomfort or injury.

Encouraging regular breaks and stretching exercises is important for preventing stiffness and promoting blood circulation throughout the workday. Prolonged periods of sitting or repetitive tasks can lead to muscle fatigue and tension, so it’s essential to encourage employees to take breaks and move around regularly.

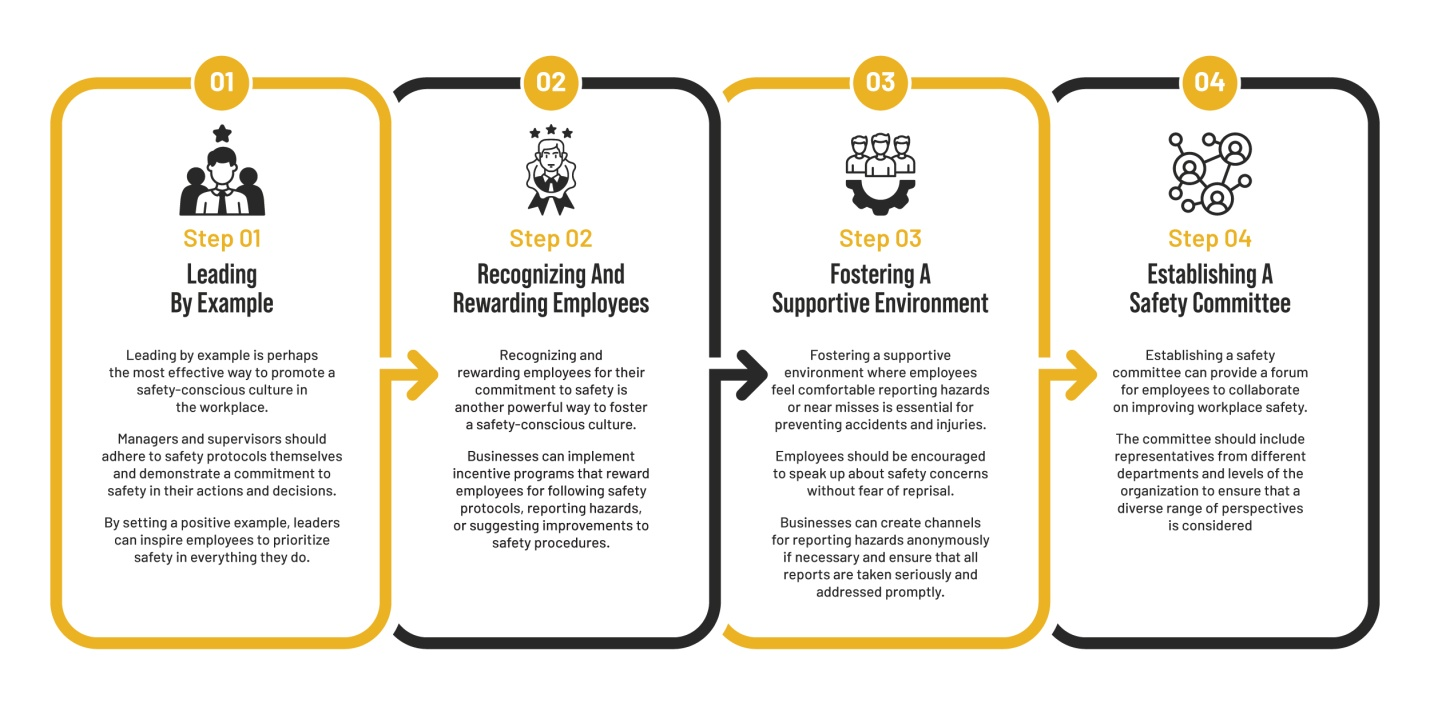

Creating a culture of safety in the workplace requires a multifaceted approach that encompasses training, equipment maintenance, communication, and ergonomic design.

By prioritizing safety and investing in the right practices and equipment, businesses can not only prevent workplace injuries but also improve productivity and morale among employees.

At Hovair Systems, we understand the importance of workplace safety, which is why we offer a range of air-lifting bags, air-bearing modules, and air-bearing turntables designed to enhance safety and efficiency in material handling operations.

Contact us today to learn more about how our innovative solutions can help create a safer work environment for your team.

To order air lifting bags, air bearing modules, and other lifting and rigging equipment, browse our productsand discover how they can revolutionize your material handling processes.