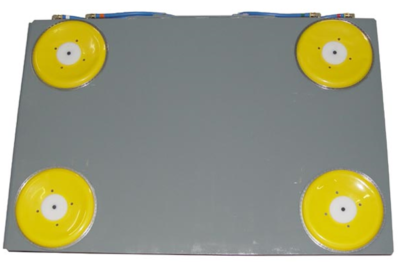

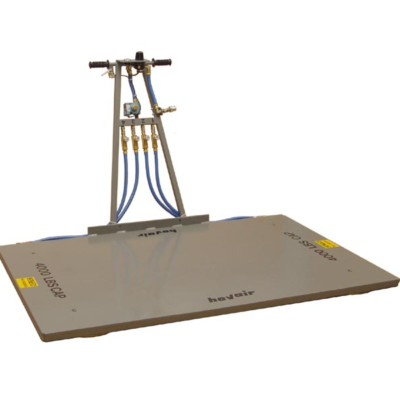

Loading skates offer a convenient platform for loading and moving heavy objects at warehouses and other processing facilities. Also known as air skates or air pallets, these devices come in various shapes and sizes to suit your needs. Continue reading “The Benefits of Using Loading Skates for Moving Heavy Objects”

Month: September 2023

Why Ergonomic Equipment Is Essential in the Workplace

In today’s rapidly advancing corporate world, the well-being of employees plays a pivotal role. Have you ever wondered what’s the secret behind employees who work tirelessly without complaints of backaches or wrist pains?

The answer lies in the adoption of ergonomic equipment in the workplace. But what makes these tools so indispensable? Let’s delve into the core reasons.

1. Elevating Employee Wellness

It’s a universally accepted fact: a happy and healthy employee is productive. The use of ergonomic equipment in the workplace has a direct positive impact on overall employee health.

Traditional office and factory equipment often forced employees into unnatural postures or repetitive motions. These conditions, over time, can lead to debilitating ailments such as carpal tunnel syndrome, lower back pain, and more.

On the other hand, Ergonomic tools are designed keeping human anatomy in mind. They promote natural postures, minimize strain, and largely negate the adverse impacts of prolonged sitting or standing.

2. Boosting Productivity Levels

When discomfort is out of the equation, employees naturally perform better. A well-designed ergonomic chair or keyboard can make a world of difference.

It ensures that the employee remains comfortable throughout the day, leading to increased concentration, efficiency, and output. By integrating ergonomic equipment in the workplace, businesses can ensure that their workforce remains at the top of their game.

4. Safeguarding Against Workplace Injuries

4. Safeguarding Against Workplace Injuries

In sectors where heavy load handling or moving heavy machinery is a routine task, the importance of ergonomics skyrockets.

Traditional methods of lifting and transporting heavy items pose severe risks. Employees often suffer from strained muscles, slipped discs, or even worse, more permanent injuries.

Thanks to modern advances, today’s ergonomic gear for moving heavy machinery ensures that workers can handle these tasks without putting undue stress on their bodies. This safeguards them from potential injuries and ensures the tasks are completed more efficiently.

5. Reducing Long-Term Medical Costs

While the initial investment in ergonomic equipment might seem hefty, it saves businesses substantial medical expenses in the long run.

Chronic workplace injuries lead to prolonged medical treatments and potential compensation claims. Businesses can curtail these impending costs by equipping the workspace with ergonomic tools.

6. Enhancing Employee Morale

It’s a no-brainer: employees naturally feel more valued when they feel their well-being is a priority. This sentiment goes a long way in improving their loyalty, reducing turnover rates, and fostering a positive work environment.

Introducing ergonomic equipment in the workplace sends a clear message that the company cares about its most valuable asset – its people.

Invest in Ergonomics with Hovair Systems!

Invest in Ergonomics with Hovair Systems!

In conclusion, the significance of ergonomic equipment in the workplace is multi-faceted. Its benefits are undeniably profound, from safeguarding employee health to boosting productivity and reducing long-term costs.

As businesses, making this wise investment today can lead to a prosperous tomorrow. And regarding quality and reliability, look no further than Hovair Systems. Make the change today for a healthier, happier, and more productive workspace.

Spinning Innovation: The Advantages Of Vehicle Turntables

The Future of Material Handling Equipment: What to Expect in the Next Decade

The world of material handling equipment is evolving at a breakneck speed.

With advancements in automation and the integration of IoT technology, the next decade promises to revolutionize how businesses manage their operations, including specialized tasks like paper roll handling equipment usage.

Automation: The Cornerstone of Future Material Handling Equipment

As businesses seek efficiency, automation is essential in material handling equipment. Automated forklifts, conveyors, and robotic arms are examples of how this technology changes the landscape.

Automation reduces the scope of human error, enhances productivity, and frees up your workforce for more complex tasks that require critical thinking and decision-making.

In particular, paper roll handling equipment is undergoing dramatic changes with automated systems capable of managing cumbersome rolls more precisely than ever.

IoT: Making Material Handling Equipment Smarter

Internet of Things (IoT) technology is another key player shaping the future of material handling equipment. With the help of sensors and real-time analytics, equipment can now “talk” to each other and central management systems.

Imagine your paper roll handling equipment alerting you when it’s time for maintenance or when there’s a system failure. This communication will enable companies to maximize uptime, predict issues before they happen, and optimize overall workflow.

Sustainability: The New Age Requirement

Sustainability: The New Age Requirement

As the focus on sustainability intensifies, the material handling sector is no exception. Equipment is becoming more energy-efficient, with electric models replacing traditional gas-powered units.

Businesses are also exploring renewable energy sources to power their material handling equipment. Sustainable practices are good for the planet and significantly reduce operating costs in the long term.

Customization and Modularity: A Tailor-Made Future

The days of one-size-fits-all are long gone. In the coming decade, expect to see a rise in customized solutions designed to meet the specific needs of individual businesses.

Material handling equipment, including paper roll handling equipment, will offer modularity and adaptability. Businesses can easily add or remove components, allowing for a more flexible and cost-effective operation.

The Intersection of AI and Material Handling Equipment

While AI may be a buzzword in many industries, its application in material handling is practical and revolutionary.

Predictive analytics, machine learning, and other AI technologies are already being integrated into the control systems of cutting-edge material handling equipment.

These systems will make real-time decisions based on massive amounts of data to optimize routes, identify inefficiencies, and adapt to changing conditions without human intervention.

Ready for the Future? Elevate Your Operations with Hovair Systems

The future of material handling equipment is not just about better machines but smarter, more sustainable, and incredibly efficient systems.

With trends like automation, IoT, sustainability, customization, and AI setting the pace, we are poised to experience an era where material handling solutions become more intelligent and adaptable than ever before.

For those keen on staying ahead of the curve, partnering with pioneers in the field is crucial. At Hovair Systems, we are committed to offering the latest in material handling solutions, including state-of-the-art paper roll handling equipment.

Contact us today to learn how we can elevate your operations to the next level of efficiency and productivity.

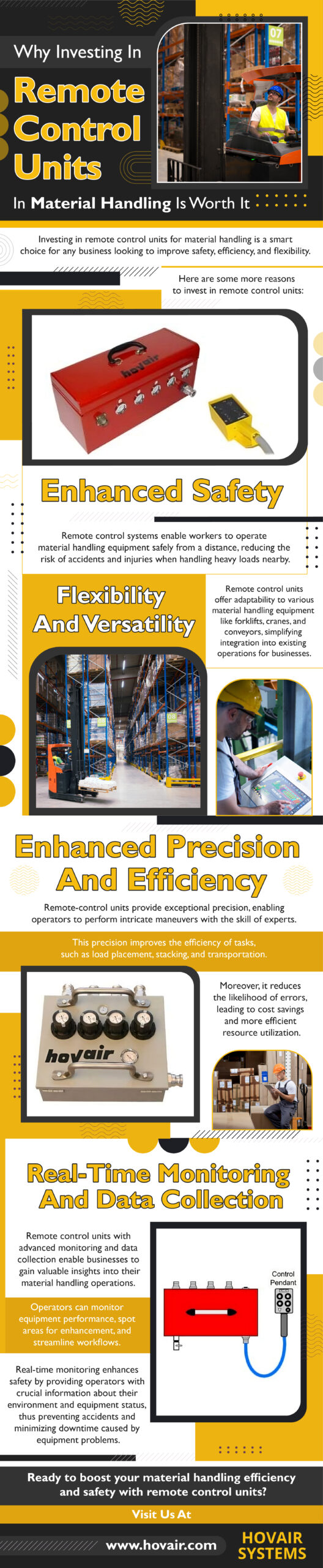

Why Investing In Remote Control Units In Material Handling Is Worth It

Air Compressor Maintenance Guide

Whether an air compressor is simply a handy tool in your workshop or garage or a crucial part of your business, you’ll want to ensure it works properly for the long haul. A surefire way to ensure this is to keep up with its maintenance needs. Continue reading “Air Compressor Maintenance Guide”

5 Tips To Help Your Air Compressor Withstand The Summer Heat

Summer is just around the corner, and it’s time to prepare for the scorching heat. Your air compressor is no exception, and it’s essential to make sure it can withstand high temperatures. Here are some tips to help your air compressor survive the summer heat. Continue reading “5 Tips To Help Your Air Compressor Withstand The Summer Heat”

Why It’s Important To Follow Service And Inspection Protocols For Rotary Screw Air Compressors

Rotary screw air compressors are an essential part of many industrial operations. They provide compressed air to power tools, pneumatic equipment, and other machinery. However, like other equipment, they require regular maintenance to function optimally. Following service and inspection protocols for rotary screw air compressors is critical for several reasons.

This blog will discuss the importance of these protocols and why you should not overlook them.

1. Ensuring Equipment Efficiency and Longevity

Rotary screw air compressors are designed to provide compressed air continuously. They consist of complex mechanical components such as rotors, bearings, and seals, which must be maintained regularly to ensure they work efficiently.

Following service and inspection protocols ensures these components are lubricated, cleaned, and replaced when necessary. This helps to prevent breakdowns and downtime, reducing maintenance costs and extending the life of the equipment.

2. Preventing Potential Safety Hazards

Rotary screw air compressors use high-pressure air to power machinery. If not maintained properly, they can pose a safety hazard to workers. For instance, if there is a leak in the system, the pressure can build up and cause the equipment to explode, injuring the people nearby. Following service and inspection protocols helps identify and address potential safety hazards before they become a danger.

3. Complying With Regulatory Requirements

In many industries, some regulations govern the operation and maintenance of rotary screw air compressors. Following service and inspection protocols helps to comply with these regulations and avoid penalties.

For example, the Occupational Safety and Health Administration (OSHA) in the United States requires that compressed air systems be inspected regularly to ensure they are safe for workers.

4. Maintaining Quality Control

Rotary screw air compressors are used to power machinery that produces products. These products must meet certain quality standards to be sold or used. If the compressed air used in the manufacturing process is contaminated, it can affect the quality of the products. Following service and inspection protocols helps to ensure that the compressed air is clean and free of contaminants, maintaining the quality of the products.

5. Saving Energy and Reducing Costs

Rotary screw air compressors consume a lot of energy. If not maintained properly, they can consume even more energy, leading to higher energy bills. Following service and inspection protocols helps to identify and fix energy inefficiencies, reducing energy consumption and lowering costs.

If you want to get your hands on high-quality and affordable air compressors, then Hovair Systems is your best option. We are one of the leading providers of material handling equipment and ergonomic equipment. We have a team of highly-skilled experts who can help you pick the right equipment, making your operations more efficient. Get in touch with us today and learn about our air compressor systems in detail.

4. Safeguarding Against Workplace Injuries

4. Safeguarding Against Workplace Injuries Invest in Ergonomics with Hovair Systems!

Invest in Ergonomics with Hovair Systems!

Sustainability: The New Age Requirement

Sustainability: The New Age Requirement