Remote control technology is benefiting every industry known to human beings. Manufacturing processes can be controlled remotely, allowing for fast solutions to any technical or structural issues with machinery, even if they are located in separate facilities.

Workers are quickly informed about concerns that need prompt attention and care, particularly if they’re not available. Issues can be addressed efficiently in this manner, reducing operational interruptions and eliminating the demand for visits. Remote management helps to prevent idleness while also boosting performance.

Workers are quickly informed about concerns that need prompt attention and care, particularly if they’re not available. Issues can be addressed efficiently in this manner, reducing operational interruptions and eliminating the demand for visits. Remote management helps to prevent idleness while also boosting performance.

Read about the advantages of remote control units in this blog.

Understanding the Concept of Remote Controlled Equipment

Take a moment to learn about remote controls before considering the advantages of utilizing them.

Masonry saws and cable saws were among the first devices in the cement production sector to incorporate radio remote controls for the production process. Remote controls are now available for cleanup robots, electrochemical deposition graters, and cornerstone drills. Many companies have updated their goods to employ wireless, Bluetooth innovation, allowing for more prompt interaction between the device and the controller. This also allows the user to remain further away from the action while maintaining complete supervision.

Understanding the Concept of Remote Control Units

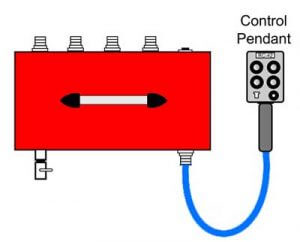

For nearly all varieties of air bearings and pneumatic lifters, remotely controlled systems are accessible. These machines allow the user complete authority over everything delivered to the network and the capacity to manage the air circulation to every particular air bearing via a single location.

Almost all air bearing kit devices have remotely controlled modules as an alternative, and the ARC module is included with the “high-lift” B-bearing set equipment.

Benefits of Remote Control Units

The following are the advantages of remote control units:

1. They Ensure Workers’ Safety

People are deploying even more gear using remotely controlled innovation to improve operations throughout the world. This improves worker safety while also making industrial automation procedures simpler. Various elements can be dangerous for people, so it’s best to stay as far away from them as possible.

Tower cranes, transshipment machinery, overhead machinery, and coil heavy machinery can all benefit from remotely controlled systems. This kind of warehouse management enables personnel to concentrate on their cargo rather than the machinery, ensuring people’s safety.

2. A Miscellaneous Working Population

Remote equipment may cater to the younger demographic that is cognizant of the health risks associated with manual tasks. Since operating a controller doesn’t comparably exhaust a contractor’s body like a conventional ground cutter or nail gun would, workers can reduce the risk of injury and remain on the job for extended periods.

3. Easy To Use

This device/system is easy to use and comes with a user’s manual. Workers can benefit from it by reviewing and simply following the instructions.

Trustworthy Materials Handling Equipment Service Providers in Seattle

Trustworthy Materials Handling Equipment Service Providers in Seattle

From vehicle turntables and lifting & rigging equipment industrial turntables to heavy load moving machines or other industrial materials handling equipment, we have solutions for all your material handling needs. At Hovair Systems, we’re committed to helping our clients automate their industrial processes and business operations and leverage technology for improving their profit. We provide air bearing services as well to our clients.

Feel free to consult our representatives for more information.

Trustworthy Materials Handling Equipment Service Providers in Seattle

Trustworthy Materials Handling Equipment Service Providers in Seattle