As industrial needs continue to become more and more complex, they need to upgrade their rigging systems. Today, manual handling or roller bearings and other means of material handling have become outdated. The primary reason why now more than ever, companies are considering investing in air-powered rigging systems is that it’s not cost-effective, but also a safe and secure method that ensures environmental safety and your employees’ health while also helping them improve their industrial productivity.

As industrial needs continue to become more and more complex, they need to upgrade their rigging systems. Today, manual handling or roller bearings and other means of material handling have become outdated. The primary reason why now more than ever, companies are considering investing in air-powered rigging systems is that it’s not cost-effective, but also a safe and secure method that ensures environmental safety and your employees’ health while also helping them improve their industrial productivity.

A company’s success and profitability heavily rely on its rigging systems. If a company uses traditional means for transportation and lifting of their products, goods, and machines from one point to another, a majority of their worker’s time and energy gets wasted. Their industrial processes become slower, and the overall industrial outputs start lacking behind that of their competitors.

If you need to optimize your industrial workflow and speed up your industrial processes, you certainly need to invest more in rigging equipment. Air-powered rigging equipment also helps you reduce your industry’s negative environmental impact and lower your bills and mitigate fuel wastage.

So, What’s Rigging Equipment

Workplace injuries cost businesses about $62 billion every year. If you need to move heavy loads in your industrial facility, you need to make sure that your employees’ safety isn’t compromised. It’s not just important to keep yourself protect your business from huge compensation costs, but as an employer, it’s your moral responsibility as well.

Workplace injuries cost businesses about $62 billion every year. If you need to move heavy loads in your industrial facility, you need to make sure that your employees’ safety isn’t compromised. It’s not just important to keep yourself protect your business from huge compensation costs, but as an employer, it’s your moral responsibility as well.

Rigging equipment refers to the material handling tools you need to lift and support objects. Whether you work on a construction site or an industrial project, you should use high-quality rigging equipment to prevent accidents and injuries. Regardless of how dangerous your location is, you can use advanced rigging equipment to make load movement more convenient, simpler, faster, and seamless.

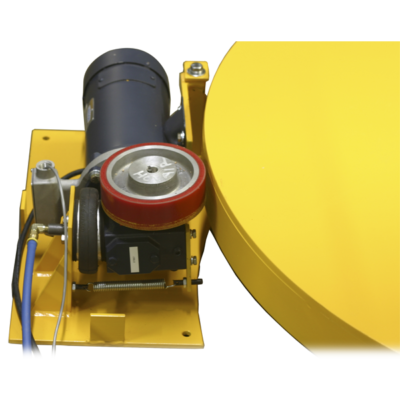

Rigging equipment refers to all tools you use for lifting loads, including but not limited to ropes, chainsaws, pulleys, shackles, turnbuckles, slings, turntables, or cables. But, the air-powered rigging systems offer unparalleled features and tremendously boost your industrial processes. It’s because air-powered systems work on the principle of air film technology. They’re designed to drift heavy objects across a surface over a thin air film. This technology helps to keep your surface in good condition as they don’t just reduce friction but also help make the weight virtually zero. Air casters are typically frictionless and omnidirectional and need minimal force to operate.

Turning forklifts and other heavy loads is the biggest challenge for industrial operators. However, air bearings and other air-based load moving tools don’t need any additional force for turning or changing direction.

Air-powered rigging equipment may also come with remote control units to help you get greater control over your systems and monitor their pressure, compensate load distribution, and other working conditions.

Factors to Consider While Choosing Rigging Equipment for Your Company

Environmental Conditions

Environmental Conditions

Traditional rigging equipment typically comes with environmental limits. That is to say, they may operate well in a regular climate but may not perform with the same efficiency when the weather is extremely cold, hot, or in a salty environment.

If your manufacturing unit, industrial facility, or construction site resides near a beach or a saltwater body, or somewhere there’s an exceptionally high or low temperature, try using air-powered rigging systems instead of the traditional ones. Air-powered systems are independent of weather conditions and give a high performance under all environmental conditions.

Quality

If you want long-term profitability for your business, never compromise on the quality of your rigging equipment. Poor quality equipment can lead to accidents, slow down your industrial processes and negatively affect your employees’ health.

Besides, if you purchase cheap rigging equipment, it may start malfunctioning in a very short time. You’ll have to invest loads of money on their repair and maintenance, and they’ll certainly cost you more in the longer run.

Make sure you’re purchasing rigging equipment from a reliable company that has a track record of manufacturing these products, is always updated with the latest technology, and leverages advanced technologies to improve their equipment’s performance.

Load Type and Weightage

If you’ve decided to purchase rigging equipment for your company, you’re on the right track. But you also need to analyze your systems before looking for other systems to add to your inventory.

All types of rigging equipment come with a certain load capacity. Air-powered systems offer a large capacity, but you should seek help from the manufacturer and make sure that they can bear the weight of your goods. Unlike other rigging equipment, air-powered rigging tools don’t wear, and hence they’ve become a top choice of several industries worldwide.

Things to Look for in Rigging Equipment

Make sure it offers a larger capacity to facilitate the movement of medium to heavy loads.

Make sure it offers a larger capacity to facilitate the movement of medium to heavy loads.- Your air bearing systems should offer a fast disconnect and connect couplings at every hose connection.

- Make sure that your workers can quickly remove or replace hose fittings when there’s an emergency.

- Your air bearing systems or other rigging equipment should feature premium quality pressure regulator control systems and operate with the same efficiency level on uneven surfaces as they’d on a smooth surface.

If you’re purchasing an air bearing kit or a rigging set, you should also ensure that it consists of sufficient air bearing elements, air hoses, pneumatic control box, and load modules. A reputable material handling equipment company may also offer air supply hoses, air jacks, and alternative hose lengths.

Industrial Accidents Associated with Traditional Rigging Equipment

A majority of industrial equipment in the US takes place because of the manhandling of rigging equipment. Most commonly, cranes, forklifts, and other traditional means of equipment handling start malfunctioning because of the following reasons:

- Overloading of the rigging equipment

- A side pull because of which the crane may tip over, leading to enormous damages

- Outrigger failure

- Control confusions

- Rigging equipment gets stuck because of pedestrians, other equipment, or by a moving load.

- Contact with the power-line

- Killer hooks, i.e., crane hooks that lack a mechanism through which it can keep the load in the crane’s hook if it bounces.

- Dismantling or Improper assembling of the equipment

- Hoist limitations

- Boom buckling

- Overturning of the equipment

- Turning a turntable unintentionally

- Oversteering or crabbing

- At the entry or exit of a particular location

- Two blockingis a type of accident that takes place when the hook of a crane comes in contact with its stationary block at the tip, exerting extra pressure on the hoist line. If this happens, the hoist may break, causing the load to fall and eventually causing havoc on the industrial site.

What You Can Do

The best way to avoid these situations is to use the latest rigging equipment that works on the principle of air film technology. By leveraging air-powered tools for equipment handling, you can substantially reduce your staffing costs as well as industrial downtime. This equipment requires considerably lower force and energy to operate and minimum manpower to maneuver and move. These features of air casters really come in handy if you need more precision and accuracy in your work or if you operate in a congested or narrow space.

Air casters can also be used along with traditional rigging equipment, like conveyors, cranes, or forklifts. Sometimes plant managers fail to install rigging equipment in their facilities, because of the limited space or other system limitations. Under this situation, they’re left with the only choice of using air casters. At first, purchasing an air caster may seem a little costly, but you’ll soon notice a massive difference in your industrial productivity and progress after installing them. Air-powered rigging tools can help you make the best use of your space.

You may already know that your employees’ mood heavily relies on their work environment. A messy and damaged workplace doesn’t only cast a negative impact on your employees’ mood but also damages your reputation in the market.

Because of these reasons, several companies have started paying particular attention to the maintenance and upkeep of their industrial facilities. If you’re also concerned about the overall look of your facility, you should make sure that the floors are of their best quality. Just like a person’s shoe can determine their personality, your company’s flooring can determine how much attention you pay towards tiny details of your products. Keeping the floors in good condition is especially important for retail businesses and stores. The best feature of air-powered rigging equipment is that they cause virtually zero damage to the floor. When you use rollers or wheels for moving equipment, they scrape the floor, or overload it, falling right through it.

You can seamlessly resolve these floor loading problems and issues by using air casters. It spreads the load over a larger area, which eventually reduces the net load over the floor.

Rigging Safety

Regardless of the quality of equipment you use, you should be careful about the following safety rules.

Regardless of the quality of equipment you use, you should be careful about the following safety rules.

Adequate Usage

- Make sure your workers are properly trained and educated about the usage of rigging equipment and common hazards associated with these kinds of jobs. Every rigger in an industry must be able to effectively control the loads throughout the moving process. They should also help in landing the load securely to their destination and make sure that it’s disconnected once the movement completes.

Compliance with OSHA Standards

Make sure that your industrial operators comply with OSHA Riggers also need to take care of their personal safety. They must wear steel shoes at all times and make sure that their shoes consist of steel toes to protect them against injuries when the loads are unintentionally dropped. In addition to this, they also need to wear safety glasses and hard hats to guard their eyes and head from falling loads. To protect their hands, riggers should wear heavy leather gloves as they can become damaged by braided wires, ropes, or other sharp objects.

Make sure that your industrial operators comply with OSHA Riggers also need to take care of their personal safety. They must wear steel shoes at all times and make sure that their shoes consist of steel toes to protect them against injuries when the loads are unintentionally dropped. In addition to this, they also need to wear safety glasses and hard hats to guard their eyes and head from falling loads. To protect their hands, riggers should wear heavy leather gloves as they can become damaged by braided wires, ropes, or other sharp objects.

Environmental Awareness

- Rigging operators are always familiar with the environmental conditions around, where the equipment is operating, its features, and its settings.

Rigging Techniques

- Rigging operators should also be familiar with different rigging techniques and need to have sufficient experience of working in the field. All the riggers in your industrial unit must know the general weight of your industrial loads’ individual weight of every product being transported or lifted, and they must be able to select and attach a compatible sling when there’s a need. They also need to have expertise in using the hitch that can balance the load and hold it as well.

Identify Unsafe conditions

- A company’s rigging operators should be smart enough to notice unsafe conditions and stop rigging procedures right then and there when there’s a need.

Anticipate Issues

- Rigging operators should be able to anticipate rigging problems that may occur and take necessary precautions.

Understand User Manual

- Rigging operators should be trained to read and understand the features and working of the rigging equipment they’re using and must be able to strictly comply with all the conditions.

Why Air-Powered Rigging Tools are the Best Choice for Industrial Customers

Maintaining your industrial systems at their peak performance is an ongoing procedure. By using air bearings and other air-based rigging tools, you can;

Maintaining your industrial systems at their peak performance is an ongoing procedure. By using air bearings and other air-based rigging tools, you can;

- Reduce your energy bills and equipment repair costs

- Improve your system’s performance and reliability

- Enhance industrial productivity

- Mitigate unscheduled industrial downtime

Premium Rigging Equipment at Affordable Prices

You can get premium air bearings and other rigging equipment from Hovair Systems at cost-effective rates. We’re known as one of the top platforms that manufacture industrial turntable Systems, durable air bearings, and lifting & rigging equipment for large–scale and small-scale industries. We have more than 5 decades of demonstrated experience in the Air Bearing and Air Caster industry. Feel free to get in touch with us if you need help in moving heavy machinery, or want to learn more about our products.

You can get premium air bearings and other rigging equipment from Hovair Systems at cost-effective rates. We’re known as one of the top platforms that manufacture industrial turntable Systems, durable air bearings, and lifting & rigging equipment for large–scale and small-scale industries. We have more than 5 decades of demonstrated experience in the Air Bearing and Air Caster industry. Feel free to get in touch with us if you need help in moving heavy machinery, or want to learn more about our products.

Environmental Conditions

Environmental Conditions Make sure it offers a larger capacity to facilitate the movement of medium to heavy loads.

Make sure it offers a larger capacity to facilitate the movement of medium to heavy loads. Make sure that your industrial operators comply with

Make sure that your industrial operators comply with