Countless unique ways are followed for moving heavy loads or equipment in industries across the globe. Previously, heavy machinery movers and riggers relied on equipment like lift trucks, rollers, and cranes to inch massive machines or transport oversized loads into place.

With the advancements in technology coupled with the rising demands for safer workplaces, crews are now embracing the ease of use and safety benefits of air casters to efficiently overcome challenging load movement and transportation tasks.

Fun Fact: Did you know that pneumatic technology was originally discovered in the 1950s? While it has been in the market for so long, it wasn’t until recently that the evolving industrial landscape made stakeholders realize its advantages as a modern means to move equipment, machinery, cargo, and products.

The contemporary plant floor layout has become dynamic, requiring constant adjustments to keep up with the production needs. As technology advances, the management tries to add, rearrange, or replace equipment to increase the productivity of the plant.

It’s not just processing equipment or machinery that is on the move. In many operations, enormous assemblies need to be inched gently through tight quarters as they make their way through the process. Air casters are ideal for all these applications.

Before we move on to the many benefits offered by the revolutionary air casters technology, let’s briefly learn some basics to understand how pneumatic tools work.

Air Caster Technology: The Basics Behind a Powerful Moving Technology Many Haven’t Heard Of

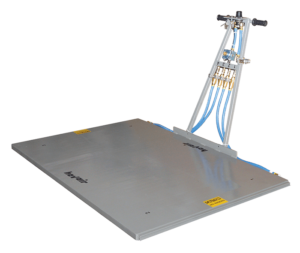

Air skids, air pallets, air pads, air bearings, air film—air casters go by several names. The technology is commonly used to lift and move awkward, heavy, unbalanced, or delicate loads on a film of compressed air. From soy sauce to 100-ton locomotives, air casters aid the manufacturing and transportation of a diverse range of products.

The pneumatic technology works by forming a lubricating film of air between the surface and the load, similar to air hockey tables. Then, a wear-resistant, flexible diaphragm gets inflated with compressed air to form a seal with the surface. The compressed air inflates the tube beneath the air caster. When the tube is completely inflated, a pressurized air pocket forms beneath the plat, which helps lifts the structure above the load pads.

Like hovercrafts, the load floats on this almost frictionless layer, allowing it to move in virtually any direction. The weight and size of the load will determine the size and number of air casters required to safely complete the task. The compressed air requirements also vary as per the size and weight of the load, the number of air casters, and whether the system being used is heavy-duty or standard.

Air casters are also compatible with buildings with lower flood-load capacities. However, leveled, smooth, non-porous, flat, and low friction surfaces are best suited for optimal results. On a feasible surface, air bearings help move difficult or heavy objects with only one pound force required for moving a thousand pounds, which is ten times better than rollers or wheels.

Air Casting Technology: The Benefits You Need to Know

Air casters significantly help reduce manpower and downtime costs while making the entire process much safer. Unlike wheeled equipment or rollers, air bearings are omnidirectional.

They require very little manpower to maneuver, which means they provide excellent value in tight spaces. They’re precise and can thread enormous components between equipment, shelving, columns, or those in the middle of moving paths.

Floating loads on air pallets make it easier to traverse corners, spin the load in and out, or make U-turns. Even the most staggeringly heavy loads can be moved safely by a small crew, sometimes even a single person, which makes the process much more cost and time efficient.

Air casters may be used as a standalone load-moving option where it’s impossible to install conveyor systems or cranes. However, they are also widely used in conjunction with traditional material handling equipment such as forklifts, cranes, and conveyors. Some plant managers also suggest purchasing air pallets to make efficient use of the areas surrounding installed conveyor systems or cranes.

The best part is that air casters help keep the floor safe. No dents, cuts, or floor damage, along with low floor load, makes them stand out as the safest and most convenient load-moving method. This is because rollers and wheels used to transport heavy loads often lead to floor scrapping or even falling through some of the floors. With air bearers, the risk of floor loading is averted because the loads are evenly spread out over vast areas, sometimes much larger than rollers or wheels. In a nutshell, the net floor load with air bearings virtually remains the same as what it would be if a person walked across it.

The ever-evolving technological advancements have helped improve air caster technology more than ever before. The latest caster designs can handle much higher pressures to move much heavier loads easily. Here are some details regarding how air casters provide safety and production benefits.

Maneuverability

Loads carried on air films are much more convenient to navigate in place than the ones moved on traditional wheeled casters. Most floors allow moving an average of 5000-pound load with only five to thirty pounds of force. As opposed to this, wheel casters will need you to exert at least 300 pounds of force to move the same load.

Altering the course is also quite simple with air casters. Thanks to the omnidirectional feature, all you need to do is apply force in the direction you want to move in. With rollers and wheeled casters, changing directions can be complicated as it requires multiple redirections to position the wheels to move in the desired direction.

Even if you use ‘heavy-duty’ wheeled casters with little start-up resistance and low friction or ones equipped with damping vibration features, it will still be difficult to manoeuvre them once they’re loaded. Chances are, the load will need to be lifted to turn the wheels of the caster. Conversely, the load can be precisely aligned and positioned with air casters, regardless of the load’s weight or size.

Tight Spaces

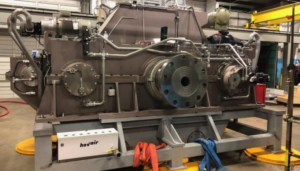

Air bearings are used in a wide variety of industries, including but not limited to military and defense, locomotive, manufacturing, automotive, wind energy, steel, construction, entertainment, mass transit manufacturing, shipyard, spacecraft, and so on.

The air caster system can fit even where overhead lifts, cranes, and forklifts can’t. Since the air films or cushions easily change direction, they’re used in several materials handling operations and applications where large or heavy products make their way through production.

Even in areas where the floor space might be tight to enable other means of material movement, air casters provide a safe and efficient way for workers to complete the task at hand.

Sensitive Loads

Air pallets smoothly glide along most non-porous surfaces, including smooth concrete, linoleum, vinyl, and raised tiles found in the majority of the facilities. But they also work seamlessly on porous surfaces as long as a plastic or metal sheet overlay is laid down.

You can get specially designed air casters for machine tool bases with slots, floors with steps and gaps, or wood-planked floors. The membrane enclosure meters the airflow rate to accommodate the unevenness.

If the load you’re trying to move is sensitive to jarring or vibration, the flexible caster bag or inflated film conforms to the imperfections of the surface to provide a compliant suspension. You’ll find caster wheels to be a lot less flexible in this scenario as they’re likely to transfer every floor bump to the load.

Hovair’s air casters can carry loads across sheets of water or wet floor, as long as the liquid doesn’t come into contact and degrade the system’s components. You can also find air pallets that use machine-tool coolant or water as the working fluid surrounding the air caster.

Even if the air supply is suddenly cut off, the air inside the pallet doesn’t instantly bleed out, which further helps keeps the load secure. It isn’t subject to shock from sudden pressure drop. But once the entire air escapes the film, if the load is resting on the landing pads, it will no longer be movable.

Safety and Ergonomics

Air casters allow a small crew and even a single person to safely control and move loads weighing up to 5000 pounds, which is more than the weight of an average four-wheeler vehicle. Power traction drives are available for heavier loads requiring extra force or steering.

Typically, the force required to move a certain load is calculated by multiplying the determined surface factor by the load weight. The surface factor refers to the level of smoothness and levelness of a surface.

One potential issue that air casters have in common with wheeled counterparts concerns traversing sloped or slanted floors. The safety rule of thumb is that one individual can move up to 5000 pounds on a particular shop floor with a 1/4th inch slope over ten feet. Conceivably, the person may be able to move heavier loads on the air caster system, but since the load size variation poses a risk, it isn’t advisable.

Minimal Maintenance

Air pallets are incredibly convenient when it comes to maintenance. Since they have no loose parts, they require no extensive lubrication or maintenance. Even when they’re dirty, you can simply get them cleaned with water and mild soap. If some substance accumulates on the fabric of the caster, you can use acetone to wipe it off with a rag. However, once it is cleaned, ensure that the air caster properly dries before any load or air pressure is applied.

No Floor Damage

Moving heavy loads on rollers or wheel casters can cause significant damage to the floor. From wearing concrete grooves to ruining expensive epoxy floors, wheeled casters can cost you more in the long run.

Since loads supported by air pallets ride on cushioned air, the loads are moved without the floor coming into contact. Moreover, air casters evenly spread out the load over a larger area, so the structural damage risk for floors is reduced further

Although air casters aren’t complex to use, it’s best to reach out to air caster experts at Hovair Systems. They can help you determine the number of air casters you will need, the kind of support system you must streamline, and the best way to position them to optimize efficiency.

If you’ve made up your mind or need more information before switching to pneumatic-powered tools that make moving heavy equipment much easier and safer, we’re here to help.

Hovair System uses state-of-the-art technology to manufacture its equipment that can help in various industrial applications. We’ve helped several businesses in diverse industries benefit from the safety, ease of use, and maneuverability offered by robust, heavy loads moving solutions.

We’re one of the leading providers of air casters, air bearings, and other rigging equipment to industries in the country. Our over five decades’ worth of experience in the industry has helped us develop a sound understanding of the load-moving needs of modern industries.

Check out our premium quality and ergonomic lifting & rigging equipment, air bearings, and industrial and vehicle turntable systems. We’re also recognized as one of the leading platforms that design and build durable air bearings, air caster, air beams, heavy load carriers, air compressor tools, paper roll handling technology, automated guided vehicles, automobile turntables, commercial turntables, and many more heavy load management devices, and automated equipment for handling of heavy loads.

Hovair Systems has developed an extensive list of clientele, including some of the world’s most renowned companies, such as Lockheed Martin, NASA, Hewlett Packard, Boeing, Goodrich Aerospace, Siemens, Pilkington, and others. We have produced reliable, affordable, and durable weight management solutions for small and large manufacturers.

We adhere to all OSHA guidelines, including Process Hazard Analysis (PHA) requirements, among other safety standards, to ensure that the team and customers are safe and secure.

To gain a better idea of how pneumatic tools work, browse our blog section. You can also email us or give us a call to learn more.