The American boatbuilding sector has a long history back to the American Revolution. The USA has three long shorelines and also multiple docks and waterways where shipbuilding enterprises have operated for over two hundred years.

In recent years, many manufacturers have started using air bearing in the shipyard industry. An air bearing is fundamentally a non-contacting system whose operation is based on air film technology. Unlike conventional bearings, air bearings use gas or air film as a lubricant to facilitate a frictionless load-bearing interface between surfaces in a relative motion.

In recent years, many manufacturers have started using air bearing in the shipyard industry. An air bearing is fundamentally a non-contacting system whose operation is based on air film technology. Unlike conventional bearings, air bearings use gas or air film as a lubricant to facilitate a frictionless load-bearing interface between surfaces in a relative motion.

Take a look at this guide to understand the importance of air bearing in the shipyard industry.

The US Shipyard Industry

The commercial shipyard sector in the United States is made up of companies that specialize in running ports, which are permanent sites containing dry docks and manufacturing machinery. Shipbuilding, maintenance, transition, modification, fabrication of constructed cruise liner and container parts, and other private practices are all part of the shipyard’s operations. Beyond the shipyard, the sector is comprised of industrial and other enterprises that produce equipment or solutions for naval operations.

The corporate shipyard business in the United States contributed $12.2 billion in annual revenue in 2019. On a national level, cumulative output production related to the sector was $42.4 billion in the Gross domestic product in the last two years.

Application of Air Bearings in the Shipyard Industry

At first, using air bearings can sound like a costly investment to engineers and system designers, but it offers several benefits that make them worth it. From aircraft manufacturing to the entertainment and power generation industry to shipyard and vehicle manufacturing, air bearings are used in every industry you can think of.

- Because of their repeatability and high positioning accuracy, air bearings are widely used in optical grinding applications and ultra-precision machine tools.

- Since air bearings feature a “surface averaging” effect, i.e., they support load along their overall length, they mitigate all the imperfections of the surface along its length. This feature makes them highly popular for use in medical device manufacturing and optical inspection devices and equipment.

- Air bearings are contactless and frictionless. They can be used with voice coilsand ironless linear motors to develop precision stages that work as transducers or force generators. Because of this, air bearings are highly effective for creating or designing friction and tensile testing equipment.

- Unlike roller bearings, air bearings offer a more stable and straighter motion because their operation is independent of the surface irregularities, texture, or surface finishes.

- Air bearings allow you to seamlessly and silently conduct heavy-duty transportation. These operations are typically smooth and silent. Unlike ball bearings or roller bearings, air bearings don’t vibrate or produce any unnecessary noise.

Air Bearing Service Provider in the USA

Air Bearing Service Provider in the USA

Regardless of the type of industry you work in, you can use air bearings to improve your industrial performance. If you want to get air bearings for your specific industrial needs, you should consult an experienced and reputable firm before investing in air bearings.

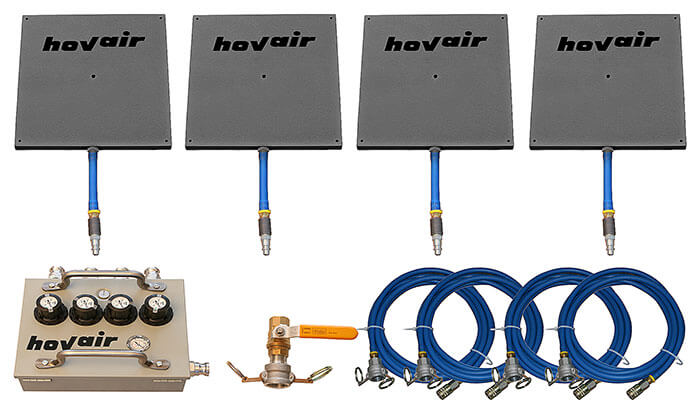

Hovair Systems manufactures a wide range of industrial tools and material handling equipment, including industrial turntables, vehicle turntables, automated guided vehicles, heavy movers, moving heavy loads, air beams, heavy load handling systems, air bearing modules, and air compressor tools.

Get in touch with Hovair Systems to learn more about their services.

Air Bearing Service Provider in the USA

Air Bearing Service Provider in the USA