Hauling heavy equipment is a task fraught with risks, challenges, and potential hazards. Whether you’re moving construction machinery, industrial equipment, or oversized loads, ensuring safety, compliance, and operational success is paramount.

Countless accidents occur each year due to improper handling, inadequate planning, or neglecting essential safety measures. As we delve into the intricacies of heavy equipment hauling, it becomes evident that mitigating risks is not just a priority but a necessity for the well-being of personnel, the protection of assets, and the smooth execution of projects.

At Hovair Systems, we understand the complexities involved in moving heavy objects. Our solutions provide unparalleled versatility, portability, affordability, and eco-friendliness. As we explore the essential risks associated with hauling heavy equipment, our solutions stand ready to address these challenges effectively.

In this blog, we’ll dissect the critical risks involved in hauling heavy equipment, offering insights into mitigation strategies and best practices.

Equipment Selection:

Selecting the appropriate heavy load handling systems is a critical step in ensuring the safe and efficient transport of heavy equipment. The consequences of choosing inadequate equipment can be severe, including accidents, delays, and damage to both the equipment and surrounding infrastructure.

Let’s delve deeper into the considerations for equipment selection:

1. Load Capacity

Understanding the weight of the equipment being transported is fundamental to selecting the right handling system. Choosing equipment with a load capacity that exceeds the weight of the load provides a safety buffer and ensures stability during transport.

Safety Buffer: Opting for equipment with a higher load capacity than the weight of the load being transported helps mitigate risks associated with unexpected factors such as uneven terrain, sudden movements, or changes in weather conditions.

Stability Enhancement: A handling system with a sufficient load capacity ensures that the load remains stable throughout the transportation process, reducing the likelihood of tipping or shifting. This stability is crucial for maintaining control and preventing accidents on the road.

2. Stability:

Stability is paramount in preventing the tipping or shifting of the load during transport, as instability can lead to accidents, damage, and even fatalities. Several factors contribute to stability considerations:

Size and Shape: The size and shape of the heavy equipment play a significant role in determining the stability requirements of the handling system. Irregularly shaped or asymmetrical loads may require specialized handling systems to maintain stability.

Terrain Considerations: The terrain over which the equipment will be transported must also be taken into account. Uneven or rough terrain can exacerbate stability issues, necessitating robust handling systems capable of adapting to varying conditions.

Load Distribution: Proper distribution of the load’s weight is essential for maintaining stability. Ensuring that the load is evenly distributed and properly secured minimizes the risk of imbalance and reduces the likelihood of accidents during transport.

3. Compatibility:

Ensuring compatibility between the heavy load handling system and the equipment being transported is essential for a seamless operation. Several factors must be considered to ensure compatibility:

Size and Shape Matching: The handling system must be capable of accommodating the size and shape of the equipment being transported. Oversized or irregularly shaped loads may require customized handling solutions to ensure a proper fit.

Weight Distribution: The weight distribution of the equipment must align with the capabilities of the handling system to prevent overloading or imbalance. Evenly distributing the weighthelps maintain stability and reduces stress on the handling equipment.

Integration with Other Equipment: Compatibility extends beyond the handling system itself to include integration with other equipment and machinery involved in the transportation process. Ensuring seamless interaction between components minimizes the risk of operational disruptions and enhances efficiency.

Transportation Planning:

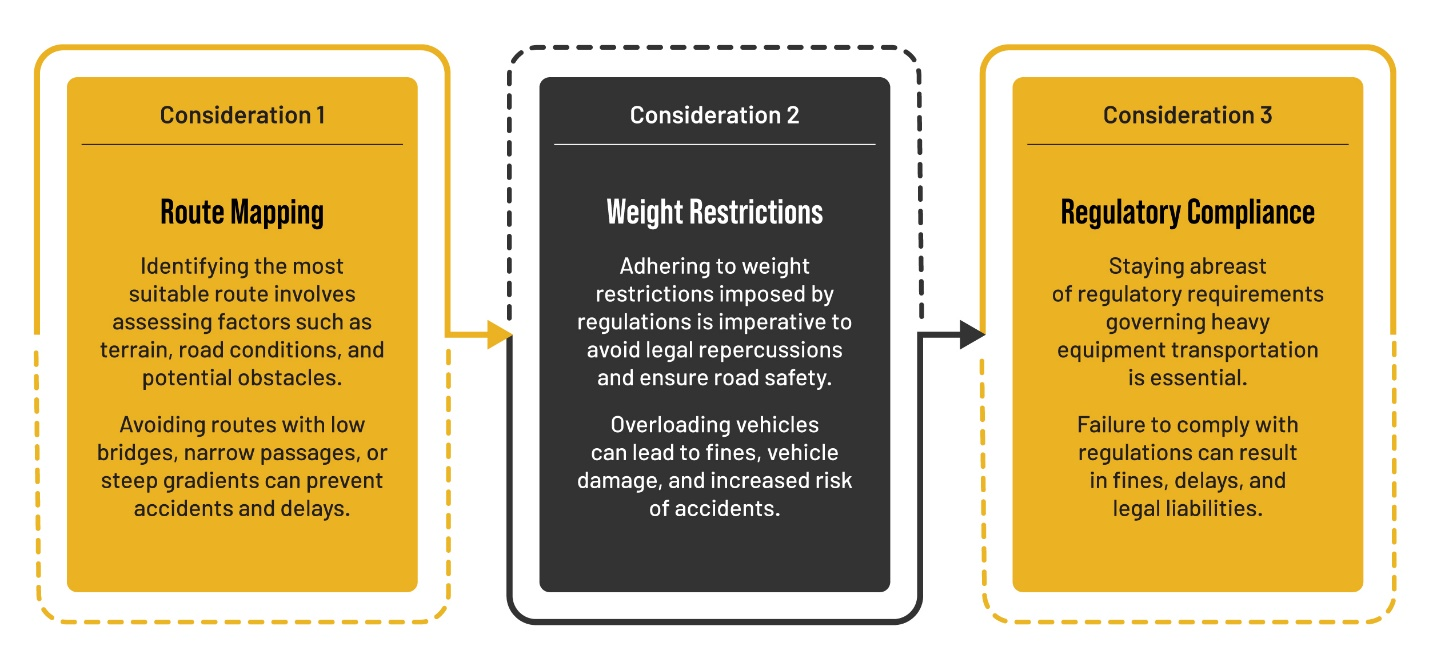

Comprehensive transportation planning is indispensable to mitigate risks associated with heavy equipment hauling. From mapping out the route to evaluating site conditions, thorough planning lays the groundwork for a safe and successful transport operation.

Safety Protocols:

Implementing robust safety protocols is non-negotiable when it comes to heavy equipment hauling. From training personnel to enforcing safety measures, prioritizing safety minimizes the risk of accidents, injuries, and costly litigation. Here’s how to ensure safety:

Personnel Training: Providing comprehensive training to personnel involved in loading, unloading, and transportation is critical. Training should cover equipment operation, safety procedures, and emergency protocols to mitigate risks effectively.

Safety Guidelines: Establishing clear safety guidelines and protocols ensures consistency and compliance across operations. Regular safety briefings, inspections, and audits reinforce safety consciousness and reduce the likelihood of accidents.

Emergency Preparedness: Developing contingency plans and emergency protocols enables swift and effective response to unforeseen events. Equipping vehicles with emergency supplies, communication devices, and first aid kits empowers personnel to handle emergencies and minimize their impact.

Mitigation Strategies

1. Preventive Maintenance:

Regular inspection and maintenance of heavy machinery lifting equipment are paramount to ensuring optimal performance and mitigating the risk of accidents. Proactive maintenance addresses mechanical issues before they escalate, minimizing downtime and enhancing safety.

2. Load Securement:

Properly securing the load using appropriate restraints, chains, and straps is essential to prevent shifting during transit. Conducting a thorough inspection of load securement before departure reduces the risk of load displacement and associated hazards, such as road debris or equipment damage.

3. Emergency Preparedness:

Developing comprehensive contingency plans and emergency protocols is essential to respond effectively to unforeseen events. Equipping vehicles with emergency supplies, communication devices, and first aid kits facilitates prompt response and minimizes the impact of emergencies on personnel and assets.

Hauling heavy equipment poses inherent risks that necessitate careful planning, adherence to safety protocols, and the use of appropriate equipment. By identifying potential hazards, implementing mitigation strategies, and prioritizing safety, organizations can minimize the likelihood of accidents, protect personnel, and safeguard valuable assets.

At Hovair Systems, our range of heavy load handling systems is designed to streamline the transportation process, ensuring efficiency, reliability, and peace of mind. Contact us today to discover how our innovative solutions can elevate your heavy equipment hauling operations.

Ready to streamline your heavy equipment hauling operations? Explore our range of heavy load handling systems and experience the difference with Hovair Systems.