It’s no secret that workplace accidents are costly; not only financially but also in terms of employee health and morale. Manual material handling systems expose employees to various potentially dangerous and strenuous activities that threaten their safety and your facility’s productivity.

According to OSHA, the top areas where workplace accidents occur are manual lifting and handling, loading docks, materials storage, forklifts, and conveyors. Safeopedia further confirms that given the nature of warehouse work, injuries from pushing, reaching, pulling, lifting, trips, slips, and falls round out the top charts.

Statistics from the US Department of Labor indicate these injuries account for a quarter of all injury claims, 16% of all accidental deaths, and an astonishing 94 million lost workdays annually.

Warehouse optimization plays a crucial role in enhancing workplace safety, efficiency, and productivity. Failure to optimize the warehouse results in increased workplace accidents, delayed deliveries and space wastage. A lean warehouse that runs efficiently can make or break the company’s bottom line. Managers need to pay close attention to their warehouse layout to improve safety and efficiency.

The Importance of Optimizing Warehouse Layout

Warehouses are places of speed, and anything that drags the process can seem counterproductive. Smart business owners recognize that proper planning for safety and efficiency is essential to expedient and smooth operations.

Warehouses are places of speed, and anything that drags the process can seem counterproductive. Smart business owners recognize that proper planning for safety and efficiency is essential to expedient and smooth operations.

The warehouse’s layout must streamline operations by arranging all the processes in a logical sequence. Lower operational costs and higher productivity result from a properly planned design. But that’s not all. Let the heavy load handling experts at Hovair Systems walk you through some of the many benefits of warehouse layout optimization.

#1- Improved Safety

With such a broad nature of onsite activities, the risk of workplace fatalities and injuries is much higher in warehouses than in other occupations. Warehousing involves many different sectors, including importing, manufacturing, retail, exporting, transportation, wholesale, and various other business needs.

The warehouse layout must enable loads to move quickly through the order fulfillment process and ensure worker safety. Implement stringent policies and train workers regularly to avoid equipment collisions or situations where workers or boxes are harmed during dock loading and unloading. Make sure you plan the layout in a way that keeps workers and products safe.

#2- Maximized Space Usage

Optimizing space in the facility is one of the most crucial objectives of an ideal layout design. A properly planned layout will help maximize the space used to its fullest potential. Effective use of space allows moving loads quickly within different facility areas. Knowing all aspects of the warehouse area and size enables choosing a layout that best suits the space. You can benefit from streamlined processes, organized inventory, and, ultimately, a neat facility.

#3- Increased Productivity

Warehouse managers seek to enhance productivity by speeding up order fulfillment without compromising safety or quality. The ideal warehouse layout will eliminate bottlenecks and errors, leading to optimized operations. The plan must enable employees to work closely with other teams to ensure all processes run seamlessly and all orders are fulfilled effectively.

#4- Reduced Costs

#4- Reduced Costs

Certain warehouse layouts can be more costly to create or maintain than others. Understanding what material handling systems you need, what loads you’re handling, and where the staff should be positioned are keys to finding a cost-effective layout.

Once these elements are figured out, resource allocation can become much more effective. Having a suitable layout also enables managers to hire the right number of personnel and keep aside adequate budgets for proper warehouse and equipment maintenance to avoid costly replacements.

#5- Improved Warehouse Management

Warehouse floor plans significantly impact the larger picture of warehouse management. They create an environment where loads flow between different stations, materials are organized, orders are fulfilled on time, and stock is replenished efficiently while ensuring the staff remains safe. Ergonomic equipment and layout, therefore, can help ensure the operations run smoothly, automatically setting your facility up for success.

Key Components to Contemplate For Effective Warehouse Layouts

Unloading and Loading Areas

Unloading and Loading Areas

Depending on the current status of your warehouse, you can either incorporate unloading and loading areas into the floor plan or locate the designated areas to check for sufficient space. These are the areas that transporting and distribution vehicles have access to.

Enough space for loading and unloading can prevent bottlenecks. If the area is incorporated into the facility, the docking point will enable vehicles to unload and load goods directly inside the warehouse. But if the area is separate, you’ll need efficient material handling systems to move the goods into the docking area.

Staging Area

This area, also known as reception, is where quality control, delivery, documentation, and sorting occur. This area must be isolated from all other warehouse areas. Not allocating enough space to the staging area can create bottlenecks in many of the processes.

Therefore, ensure you create ample space for all loads to be accurately sorted, checked, and reviewed. The warehouse team can determine optimal storage once all the materials have arrived officially.

Storage Area

Many experts recommend vertical storage techniques for optimizing space. But not everything can be stored in the same way. You can use racking shelves or otherwise stack loads with excellent internal strength.

Separate static and dynamic storage to further utilize the space efficiently. Dynamic storage refers to sections where the most popular items are set up. Meanwhile, static storage comprises items that stay in stock for longer periods before being shipped out.

Separating both storage areas helps eliminate inventory mistakes while improving picking, packing, and order fulfillment time. Adding a picking area next to or inside the storage area is another great way to reduce the time spent searching for goods. These areas enable the warehouse team to make the necessary adjustments to the orders.

Dispatch Area

Items prepared in the picking area are packed in this part of the facility. Once a shipment is fully prepared, it’s held safely in the dispatching area. Unlike items in storage, items in this area are prepared as per the order. Plan this area in a way that allows a free flow of goods from storage to the loading area. It allows a swift inventory movement.

Types of Warehouse Layouts

Determining which warehouse layout will effectively meet your needs is critical for enhancing safety and efficiency. This will heavily rely on the available space and how loads move within the processes at the facility.

Determining which warehouse layout will effectively meet your needs is critical for enhancing safety and efficiency. This will heavily rely on the available space and how loads move within the processes at the facility.

Therefore, what works for one warehouse might not be ideal for another. Collecting all the necessary information and determining the goals before choosing the layout design is essential. Generally, warehouses function with three main layout types.

#1- U-Shaped Layout

The simple design of U-shaped layouts has made it so popular that it’s now recognized as the best. The layout is ideal for warehouses of any size and can be replicated anywhere easily. It involves arranging all warehouse components in a semi-circular manner, with receiving and shipping areas on parallel sides.

The storage can be located somewhere in the middle, with the reception area following the unloading and loading areas. Incorporating the picking area behind shipping also helps keep material flow streamlined to prevent bottlenecks. In addition, this type of layout also minimizes the space required, allowing employees to move loads between receiving and shipping quickly.

#2- I-Shaped Layout

I-shaped warehouses are common in large corporations with bigger warehouse spaces. Such companies experience higher production volumes, and this type of layout proves more effective since it enables a clear in-and-out load flow.

The layout boasts a straight flow from loading, unloading, storage, receiving, and shipping. It enhances optimization since it effectively utilizes the entire warehouse length. You can also keep similar materials in the assembly line format to avoid unnecessary back-and-forth movements and eliminate bottlenecks.

#3- L-Shaped Layout

L-shaped design is not as common because it’s generally chosen to accommodate L-shaped buildings. The 90-degree layout features a shipping area on one side and receiving space on the other. This layout enhances warehouse optimization because goods can flow in one direction without requiring back-and-forth movements.

Tips for Warehouse Layout Optimization

Define the Objectives

Define the Objectives

Before choosing a specific layout for your warehouse, make sure you clearly define the objectives, along with short- and long-term goals. All the goals must align with your company’s overall strategy.

Track and Label Inventory

You can eliminate errors and downtime in the warehouse by ensuring all materials and merchandise are properly labeled. Tracking all inventory is also vital for determining what’s already there, what’s needed, and the storage capacity that will be enough.

Regular Maintenance

Consistent alterations and maintenance to keep up with the changing environments or warehouse needs ensure the warehouse business continues to operate successfully. Regular maintenance helps ensure all equipment in the warehouse functions optimally. It’s also a great way to ensure the facility remains neat, has efficient quality control, and organized storage.

Leverage Automation

Automated warehouse systems ensure minimized human errors and streamlined processes. With advancements in technology, warehouse automation assists in achieving most goals set by managers much more safely and efficiently. It includes various solutions, including artificial intelligence, automated guided vehicle systems, robotics, and other warehouse equipment.

How to Select Ergonomic Equipment that Enhances the Warehouse’s Efficiency and Safety?

With the demand for warehouse facilities growing rapidly, the sector’s future will put more pressure on safety and efficiency. Businesses will seek to get more out of the limited space. There’s an increasing need for advanced, safe, and efficient solutions. The warehouse of the future will only be successful if the latest technologies are used to make order fulfillment more efficient, reduce costs, and improve productivity.

With the demand for warehouse facilities growing rapidly, the sector’s future will put more pressure on safety and efficiency. Businesses will seek to get more out of the limited space. There’s an increasing need for advanced, safe, and efficient solutions. The warehouse of the future will only be successful if the latest technologies are used to make order fulfillment more efficient, reduce costs, and improve productivity.

Most warehouses require workspaces, storage, and material handling systems. The type and size of your equipment come into play when planning the floor layout of the facility. The nature of the loads you’ll be handling determines the warehouse shelving and storage units.

Make sure you invest in ergonomic equipment that meets your facility’s needs. Proper material handling equipment is important to reduce workplace injuries, accidents, absenteeism, and downtime. It also helps minimize potential losses from improper manual material handling.

You can invest in heavy load handling systems from specialized dealers such as Hovair Systems. It’s a great way to ensure you don’t have to compromise on lifting and rigging equipment or material handling systems since we offer flexible concepts for moving heavy loads.

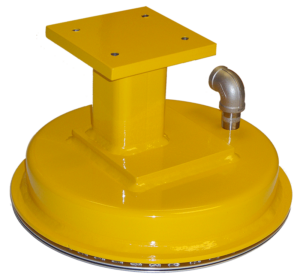

Our heavy load management solutions include durable air bearings, industrial turntable systems, air casters, air skates, air beams, air compressor tools, pallet handling equipment, load leveling airbags, air bearing kits, automobile turntables, ergonomic lift tables, heavy-duty transporters, commercial turntables, and many other air caster material handling solutions.

You can also consult with our experts for modular material handling equipment that fits your warehouse needs despite the layout type. Start the process towards an optimized warehouse by analyzing your options with an expert technician from Hovair. Just tell us about all your requirements, and let us help you find the right solution for your warehouse.

How Hovair Systems Can Help Turn Your Facility into the Warehouse of the Future

Hovair Systems is a material handling systems provider that understands how crucial heavy machinery lifting equipment is for diverse applications and industries. We offer cutting-edge pneumatic-powered tools to improve productivity, security, workflow, and efficiency in warehouses across the region.

Hovair Systems is a material handling systems provider that understands how crucial heavy machinery lifting equipment is for diverse applications and industries. We offer cutting-edge pneumatic-powered tools to improve productivity, security, workflow, and efficiency in warehouses across the region.

Partnering with us means you’ll be complying with all safety regulations as our solutions help you keep the workers and loads safe and secure. Moreover, our entire range of material handling equipment solutions is energy-efficient, durable, and cost-effective, so you won’t need to worry about reliability, maintenance, or budgetary constraints.

Email us for more information about our extensive range of ergonomic systems for moving heavy machinery.

#4- Reduced Costs

#4- Reduced Costs Unloading and Loading Areas

Unloading and Loading Areas Define the Objectives

Define the Objectives