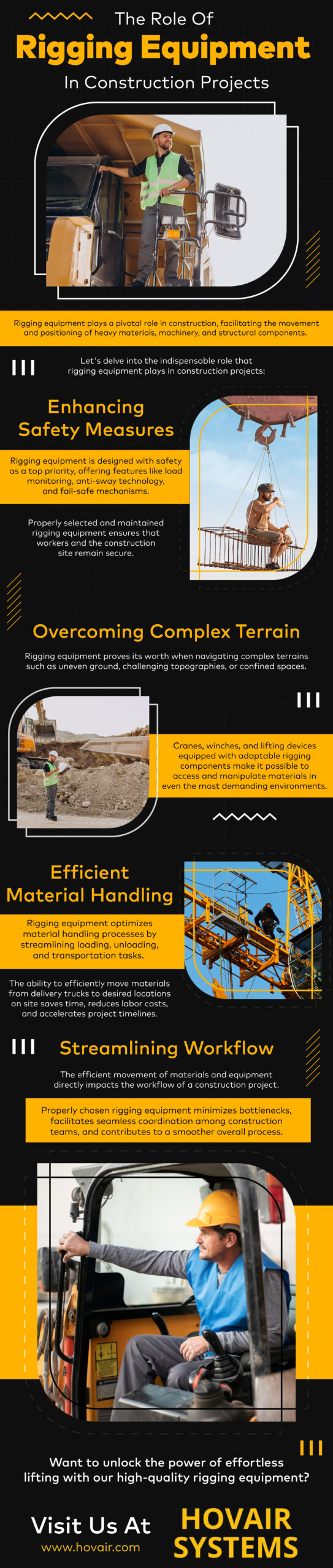

Exploring The Advantages Of Air Pallets In Warehousing

Material handling is an essential aspect of many industrial and manufacturing processes. It involves the movement, storage, and control of materials in a manufacturing plant, warehouse, or distribution center.

While material handling equipment has made it easier and more efficient to handle materials, certain materials are prone to problems during the handling process. In this blog post, we will explore the materials that are prone to problems in material handling and how Hovair Systems can help.

Fragile materials such as glass, ceramics, and electronic components are prone to breakage during the handling process. This can result in product damage, increased costs, and production delays. To avoid such problems, it is important to use appropriate material handling equipment like air bearings that can handle fragile materials without causing damage.

Hovair Systems offers a range of air bearings that are specifically designed for the handling of fragile materials. These air bearings use air pressure to float the load above the ground, providing a cushion of air that protects the load from shocks and vibrations during transportation.

Heavy materials such as metal plates, concrete blocks, and machinery components can be difficult to handle and transport. They require specialized equipment such as cranes, forklifts, and hoists to move them safely and efficiently. However, even with the right equipment, heavy materials can still be prone to problems such as slippage, tipping, and dropping.

Hovair Systems offers a range of air film products, such as air casters and air skates, which can handle heavy loads of up to 1,000 tons. These air film products use a thin layer of air to create a low-friction film between the load and the ground, making it easier to move heavy loads without damage or injury.

Hazardous materials such as chemicals, explosives, and radioactive substances require special handling and transportation procedures to ensure the safety of workers and the environment. The use of appropriate material handling equipment like containment systems, leak-proof containers, and specialized vehicles is essential to prevent accidents and spills.

Hovair Systems offers a range of air caster and air film products that can handle hazardous materials safely and efficiently. These products use a leak-proof design to prevent spills and contamination, and they can be customized to meet the specific requirements of different types of hazardous materials.

Temperature-sensitive materials such as food, pharmaceuticals, and chemicals can be prone to problems during the handling process. Exposure to extreme temperatures can cause spoilage, degradation, and loss of potency, which can result in product recall, increased costs, and damage to brand reputation.

In conclusion, the handling of materials is a critical aspect of many industrial and manufacturing processes. By using appropriate material handling equipment like air bearings and air film products, companies can ensure the safe and efficient handling of different types of materials.

Hovair Systems offers a wide range of air bearings and air film products that are specifically designed to handle different types of materials. Contact us today to learn more about their material handling solutions.

Material handling is a critical aspect of any business that deals with physical products. It refers to the movement, storage, protection, and control of goods throughout the supply chain. Material handling can be done either manually or through automated systems. Choosing the right method of material handling is crucial to ensure optimal efficiency and productivity. Continue reading “Automated vs. Manual Material Handling: What Is Best For Your Business?”

Every enterprise, big or small, continuously seeks methods to streamline its operations, striving for maximum efficiency. The answer to this quest in material handling lies in one ingenious invention: air pallets.

Understanding the air pallets advantages can revolutionize pallet handling procedures, making them seamless, cost-effective, and incredibly efficient.

Regarding pallet handling, air pallets have swiftly gained recognition as a game-changer. This is primarily because of their compact, lightweight, and incredibly easy-to-use design.

Their superiority to conventional means of handling becomes evident when we look at the numerous advantages they offer.

For starters, air pallets significantly reduce manual labor. No longer are workers required to exert immense physical effort to move hefty loads. The power of air makes maneuvering massive weights almost effortless.

This not only accelerates the material handling process but also ensures the safety of workers, minimizing potential accidents and injuries.

Another undeniable advantage of air pallets is the space efficiency they bring. Traditional means often require larger operational spaces and storage facilities.

With compact air pallets, businesses can operate within limited areas, ensuring that space is utilized to its utmost potential. This results in considerable savings in rental or purchase costs of larger spaces.

One must mention their portability before discussing air pallets. Given their compact nature, they can be easily transported from one location to another, enabling businesses to have flexible operations.

This adaptability is crucial in today’s fast-paced industrial world, where conditions and requirements change in the blink of an eye.

The benefits of air pallets are not just limited to operational smoothness. The long-term financial implications are just as impressive. Companies can expect significantly reduced equipment maintenance and repair costs by opting for air pallets.

Unlike traditional systems with many moving parts susceptible to wear and tear, air pallets have minimal components requiring maintenance. This ensures longevity and consistent performance.

Moreover, as the need for manual labor diminishes, so do the associated costs. Fewer injuries mean fewer compensation claims and medical bills. Plus, the speedier process means reduced operation hours, which, in turn, translates to cost savings.

Given the plethora of air pallets advantages, it’s evident that they are an indispensable asset for businesses aiming to excel in pallet handling.

By incorporating air pallets into their operations, companies can look for streamlined processes, increased productivity, and considerable cost savings.

Staying ahead of the curve is essential in the ever-evolving material handling world. The air pallets’ advantages are too numerous to ignore. Embracing this innovation can catapult your operations to new heights, setting you apart from the competition.

Interested in elevating your pallet handling processes? Make a decisive move towards operational excellence with Hovair Systems! Don’t let progress wait; embrace the future today.

In today’s rapidly evolving industrial landscape, innovation is the cornerstone of progress. With the advent of new technologies and material handling equipment, industrial operations are undergoing transformative changes that are redefining efficiency, precision, and scalability. Among the revolutionary solutions that are steering this transformation, lift decks and air bearings have emerged as key players.

The blend of creative engineering and modern technology has indeed sparked a transformative revolution that goes beyond the usual limits. This is leading to remarkable accomplishments in the industrial realm. Lift decks, designed cleverly to be versatile, are set to change how we move things up and down in industries. When combined with the effortless movement of air bearings, these innovations work together to solve longstanding challenges and push progress forward.

This comprehensive guide will navigate through the intricacies of these innovative industrial solutions, shedding light on their functionalities, advantages, and, most importantly, profound impact on various industrial sectors.

Industrial innovation has been an integral driver of economic growth and technological advancement. Throughout history, industries have witnessed remarkable shifts from manual labor to mechanization, automation, and now the digital age.

This journey of innovation and creativity begins with the advent of mechanization during the late 18th century. This was when the Industrial Revolution marked a pivotal turning point as manual labor was gradually replaced by machinery powered by steam engines. Factories emerged, drastically increasing production capacity and altering the socioeconomic landscape.

Then the early 20th century witnessed the rise of mass production and the assembly line, a concept popularized by Henry Ford. This innovation led to the development of standardized processes and increased productivity, enabling the production of goods on an unprecedented scale.

The latter half of the 20th century saw the emergence of lean manufacturing principles and total quality management. These methodologies are aimed at minimizing waste, optimizing resource utilization, and ensuring consistently high product quality.

As environmental concerns gained prominence in the 21st century, industries shifted towards sustainable practices and long-lasting ergonomic equipment. Innovations in renewable energy, waste reduction, and eco-friendly materials emerged, reflecting a growing commitment to environmental responsibility.

In recent years, biotechnology and nanotechnology have taken center stage. These fields hold the promise of developing innovative materials, processes, and products with unprecedented precision and capabilities. The ongoing evolution witnesses the rise of customization through additive manufacturing (3D printing). This technology allows for rapid prototyping, reduced material waste, and the creation of intricate designs previously unattainable through traditional manufacturing methods.

Lift decks have played a significant role in the ongoing industrial revolution, transforming the way materials are moved, stored, and accessed within various industrial settings. This unique and efficient material handling equipment has seamlessly integrated cutting-edge technology into traditional material handling processes, ushering in a new era of efficiency and adaptability.

Lift decks, also known as lift platforms or vertical conveyors, are mechanical systems designed to elevate heavy loads between different levels of a facility. They consist of a sturdy platform equipped with advanced hydraulic, pneumatic, or mechanical mechanisms. The design of a lift deck varies based on the specific requirements of the industry it serves. Some lift decks are built to handle massive loads in industrial warehouses, while others are designed for precision applications in cleanroom environments.

The operational principle of a lift deck is relatively straightforward yet highly effective. This modern material handling equipment features a platform attached to a lifting mechanism that raises or lowers the load vertically. This can be achieved through hydraulic cylinders, scissor mechanisms, or cable-driven systems. Additionally, modern lift decks often incorporate sophisticated control systems, enabling operators to precisely position the platform and its cargo.

In simple words, lift decks have been an integral part of the industrial revolution by modernizing material handling practices and contributing to increased efficiency, safety, and adaptability. Their ability to optimize space utilization, enhance operational workflows, and provide precise positioning capabilities has made them essential material handling equipment for all industries. As industries continue to evolve and adapt to new challenges, lift decks remain a vital tool in their pursuit of progress and success.

Air bearings have emerged as yet another pivotal component in the ongoing industrial revolution, revolutionizing the way industrial processes operate today. These remarkable devices have seamlessly integrated advanced principles of fluid dynamics into industrial applications, reshaping the boundaries of what is achievable.

Air bearings, often referred to as aerostatic or air cushion bearings, operate on the principle of a thin air film created by a controlled flow of pressurized air. This film of air eliminates physical contact between the bearing and the surface it supports, resulting in near-frictionless movement. The core components of an air-bearing system include a porous bearing surface and a sophisticated control mechanism that regulates air pressure and distribution.

When pressurized air is introduced between the bearing and the surface, it forms a cushion that lifts the load off the ground, allowing it to glide with minimal resistance. This characteristic makes air bearings highly suitable for applications that demand extremely precise and smooth movement, such as high-precision manufacturing, semiconductor production, and coordinate measuring machines (CMMs).

In summary, air bearings have significantly contributed to the industrial revolution by redefining precision, efficiency, and versatility in various sectors. Their unique ability to provide frictionless movement, exceptional precision, and vibration isolation has led to transformative advancements in manufacturing, measurement, and other critical industrial processes. As industries continue to push the boundaries of innovation, air bearings stand as a testament to the remarkable potential of fluid dynamics and their role in shaping the future of industrialization.

Air bearings and lift decks are two remarkable innovations in the realm of industrial technology and ergonomic equipment. Over time they have converged to create a symbiotic partnership that amplifies their individual capabilities, revolutionizing the way materials are moved and positioned within industrial operations.

At first glance, air bearings and lift decks may seem distinct, but their synergy lies in their complementary mechanisms. Air bearings, with their ability to create a near-frictionless interface between surfaces, facilitate smooth and precise horizontal movement. On the other hand, lift decks excel in vertical movement, effortlessly raising or lowering heavy loads between different levels.

When integrated, air bearings can enhance the vertical movement capabilities of lift decks. Traditionally, lift decks employ mechanical or hydraulic systems to control vertical motion, which may result in friction and vibration. By incorporating air bearings into the lift deck’s design, the vertical movement becomes even more seamless and controlled. The air cushion created by the air bearings reduces friction during elevation and descent, resulting in a smoother and quieter vertical motion.

The combination of air bearings and lift decks can lead to reduced energy consumption. The efficiency of air bearings in minimizing friction translates to lower power requirements during both horizontal and vertical movement. As a result, the overall energy expenditure for transporting heavy loads is significantly reduced, contributing to operational cost savings and environmental sustainability.

Precision is a cornerstone of industrial operations, and the integration of air bearings with lift decks delivers an unprecedented level of accuracy. The frictionless movement provided by air bearings, coupled with the controlled vertical motion of lift decks, ensures the precise positioning of materials or equipment. This precision is crucial in industries that demand meticulous alignments, such as semiconductor manufacturing or aerospace assembly.

Moreover, the synergy between air bearings and lift decks enhances workplace safety. The reduced friction and controlled motion minimize the risk of sudden jolts or jerks during material handling. This, in turn, reduces the likelihood of accidents and injuries, promoting a safer working environment for employees.

Industries with intricate or delicate products benefit immensely from the integration of air bearings and lift decks. These combined technologies allow for the gentle and precise movement of sensitive materials, minimizing the risk of damage or contamination. From delicate electronics to fragile glassware, the partnership between air bearings and lift decks ensures meticulous handling throughout the entire vertical and horizontal transportation process.

The future of industrial innovation holds a promise of unprecedented transformation and advancement, propelled by fast-paced technological progress. As we stand at the brink of a new era, we can expect to witness a blend of cutting-edge technologies that will reshape industries in ways we can scarcely imagine. Automation and artificial intelligence will intertwine to create smart factories and production systems that operate with unparalleled efficiency and autonomy.

Advanced robotics will revolutionize manufacturing processes, enhancing precision, speed, and adaptability. Nanotechnology will unlock new fields in materials science, enabling the creation of novel, lightweight, and high-performance materials that go beyond our wildest imaginations. Moreover, sustainable practices and green innovations will take center stage, guiding industries towards eco-friendly production methods.

Indeed, the collaboration between air bearings and lift decks represents a union of precision, efficiency, and safety in industrial operations. Their interaction not only optimizes material handling processes but also sets new standards for accuracy, energy efficiency, and workplace well-being.

Any industry that intends to survive and thrive in this fast-paced digital revolution needs to remain fully aware of the advanced technologies being introduced every now and then. If your company is on the hunt for reliable and durable material handling equipment, feel free to reach us at Hovair Systems. Our brand utilizes the power of compressed air to develop machine handling systems known to elevate efficiency and productivity. Introduce your company to ease and efficiency by contacting us today.

In a world increasingly seeking efficiency, the transport industry has witnessed numerous revolutions. From horse-drawn carriages to cranes and forklifts, the story of progress never ends.

Today, the next chapter in this evolutionary tale is our guide to air-lifting bags. This innovative tool is ushering in a new era in heavy-load transport, combining efficiency with safety in a manner previously unseen.

At first glance, air-lifting bags may appear as simple inflatable devices. However, they are far more intricate and revolutionary. These bags are made of tough, layered materials designed to bear substantial weight.

Simply inflating them beneath heavy objects, you can easily lift tons of weight, reducing the manpower and risk involved in traditional methods.

Imagine trying to lift a colossal machine or a massive block of concrete. With conventional methods, you’d need significant machinery or a team of workers. Enter the guide to air-lifting bags.

The power of air pressure does the heavy lifting by placing these bags beneath the object and inflating them. The weight gets evenly distributed across the bag’s surface, ensuring stability and security. The result? Swift, smooth, and safe transport of heavy loads.

In heavy-load transport, safety remains paramount. While effective, traditional methods often pose risks, especially when moving delicate or precariously balanced objects. The guide to air-lifting bags introduces a paradigm shift in this domain.

With these bags, the weight of the load distributes evenly, minimizing the chances of tilting or toppling. Furthermore, the inherent flexibility of these bags allows them to adapt to uneven surfaces, providing an added layer of safety.

One of the prime benefits emphasized in the guide to air-lifting bags is the drastic reduction in manpower and machinery. Gone are when you needed an army of workers or colossal machinery to move hefty objects.

Now, when positioned correctly, a few of these bags can do the job with efficiency and speed. This not only cuts down operational costs but also ensures that the task gets completed faster.

Air-lifting bags are more than a passing trend. Their implications for sectors like construction, military, and emergency services are vast. As these bags evolve in design and capability, we may soon find them becoming as ubiquitous as the crane or the forklift.

As we ride this new wave of innovation in heavy-load transport, the guide to air-lifting bags serves as a beacon, shedding light on the potential and power of this transformative tool.

Whether you’re in the construction business, military, or any sector that deals with heavy loads, these bags are worth considering.

Considering integrating air-lifting bags into your operations? Trust Hovair Systems for the best solutions. Dive into the future of heavy-load transport. Contact Hovair Systems today!

Material handling equipment is an essential component of warehouse operations. It facilitates the movement, storage, and protection of goods in a warehouse, making it an integral part of any warehouse operation. In this blog post, we’ll discuss how material handling equipment impacts warehouse efficiency. Continue reading “5 Ways Material Handling Equipment Impacts Warehouse Efficiency”

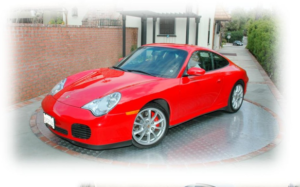

In today’s urban sprawl, space optimization is not just an architectural trend but a necessity. Amid this need for better space management, the emergence of the vehicle turntable stands out.

Pioneering a new age of automotive storage solutions, vehicle turntable uses are diverse, efficient, and relevant to modern urban living.

At the time, the concept of a car turntable seemed something out of a sci-fi movie. Yet, here we are, at a juncture where not only is it a reality, but its application has far surpassed mere novelty.

The development of the car turntable can be attributed to two primary factors: the increasing value of real estate and the need for convenient vehicle management in tight spaces.

A large part of the Vehicle Turntable Uses stems from its ability to save space. In areas where parking space is a premium, the turntable proves to be invaluable.

Instead of cumbersome multi-car garages or expansive driveways, a single turntable can rotate a vehicle, allowing it to fit or exit a space easily. No more five-point turns or tricky reversing maneuvers; the turntable does the hard work for you.

Let’s remember the sheer elegance of it all. A car turntable is about more than just practicality. It speaks volumes about the homeowner’s taste, sophistication, and appreciation for modern solutions.

Think about the awe-inspiring sight of a luxury vehicle rotating gracefully, ready to be driven into the world. It’s akin to a modern-day chariot presentation, and for the aficionados of luxury, it’s a must-have feature in their residence.

Incorporating a vehicle turntable into a property does more than just offer convenience; it elevates the property’s value. Real estate agents and property developers have noted the growing demand for homes with this advanced feature.

Thus, for those looking at it from an investment angle, considering Vehicle Turntable Uses is an intelligent step in future-proofing one’s real estate value.

The final and arguably one of the most important facets of a car turntable is the safety aspect.

In places with limited visibility, a turntable can rotate the vehicle to face the exit instead of reversing out, significantly reducing the chances of accidents. Safety and ease of use make the vehicle turntable a crucial asset in contemporary home designs.

The Vehicle Turntable Uses go beyond mere vehicle management. It blends aesthetic appeal, modern innovation, and safety enhancements. The choice is crystal clear for anyone considering the next step in automotive storage solutions.

Dive into the future and embrace the elegance and efficiency of a vehicle turntable. And if you’re searching for the most advanced and reliable turntables on the market, Hovair Systems is your ultimate destination. Elevate your vehicle storage game, and contact Hovair Systems today!

In the industrial world, there’s a silent revolution afoot, powerfully redefining material handling. What’s leading this quiet upheaval? The answer is simple: the air compressor’s industrial function. Here’s a deep dive into how this tool is changing the game.

At the heart of every efficient industrial process, air compressors work diligently behind the scenes. Their core function is to convert power into potential energy stored in pressurized air.

This air then powers a myriad of air compressor tools. This technology, as unassuming as it might sound, is driving unprecedented efficiencies in material handling.

Moving materials across production floors or warehouses traditionally required significant manpower or bulky machinery.

But with the evolution of the air compressor’s industrial function, industries are now equipped to move heavy loads with precision, reduced energy consumption, and minimal human intervention.

For instance, consider how air compressor tools have enabled the creation of pneumatic systems that lift and move heavy materials effortlessly. These systems are efficient and reduce the risk of workplace injuries.

The wider implications of this silent revolution cannot be understated. As industries embrace the air compressor’s industrial function, there’s a domino effect on operational efficiency, worker safety, and sustainability.

With decreased reliance on fuel-based machinery, there’s a reduction in carbon emissions. Additionally, the maintenance cost and downtime of air compressor tools are far lower than their electric or fuel-driven counterparts.

Moreover, embracing air compressors for material handling means less noise pollution. The machines operate silently, ensuring a quieter and more conducive working environment. This might seem small, but it contributes significantly to worker productivity and well-being.

Air compressors are not just a fleeting trend in the material handling sector. Their ability to efficiently power a wide array of air compressor tools solidifies their place as indispensable assets in the industrial space.

We can only expect these tools to become more advanced as technology advances, further revolutionizing how industries approach material handling.

The silent revolution of the air compressor’s industrial function is a testament to innovation and the continuous pursuit of excellence in the industrial sector.

As we look ahead, integrating these powerful tools promises a future of enhanced efficiency, reduced carbon footprints, and optimal workplace environments.

Are you ready to be a part of this revolution? Leap with Hovair Systems and discover innovative solutions tailored to your material handling needs. Let’s redefine the future together.

In the constantly evolving landscape of the modern industry, few tools have become as indispensable as lifting jacks.

If you’ve ever wondered about the comprehensive guide to lifting jacks, this is the place to be. These engineering wonders simplify heavy-duty tasks and ensure safety and efficiency. Let’s dive deeper.

Lifting jacks, often categorized under heavy machinery lifting equipment, have existed for centuries. Yet, their significance has amplified manifold in today’s industry.

Think about the enormous skyscrapers or the intricate machinery used in manufacturing units – their assembly and maintenance often necessitate raising colossal weights. And that’s where our trusty jacks come into play.

No longer are these tools limited to merely hoisting vehicles. In various industrial sectors, lifting & rigging equipment has become essential.

Be it the transport sector, construction, or heavy machinery maintenance, the modernized lifting jacks are here to carry the weight, literally!

For instance, railways often use them for maintenance tasks. Simultaneously, heavy containers are easily maneuvered in the shipping sector, thanks to these jack’s capabilities.

Furthermore, with digital elements and automation, these jacks have become smarter, more efficient, and, most importantly, safer.

A guide to lifting jacks wouldn’t be complete mentioning their dual advantages: safety and efficiency. With the implementation of contemporary designs and technology, lifting jacks have drastically reduced workplace accidents related to heavy lifting.

Workers can now rely on these tools to handle weights that would have been unthinkable a few decades ago.

Moreover, efficiency levels have seen a steep rise. Tasks that previously required several hours or even days can now be executed in a fraction of that time. It’s all thanks to the innovative designs and functionalities that the modern lifting & rigging equipment offers.

As industries evolve, so does the heavy machinery lifting equipment that powers them. The next generation of lifting jacks promises even more flexibility, durability, and smart capabilities.

Innovators focus on making them more environmentally friendly, incorporating features like energy efficiency and reduced carbon footprint. The road ahead is not just about lifting; it’s about lifting responsibly!

In the grand tapestry of industrial evolution, lifting jacks are not mere threads but essential pillars. As this guide to lifting jacks suggests, their role is only set to expand and become more crucial.

So, whether you’re involved in the construction business, transportation, or any other heavy-duty industry, investing in top-quality lifting & rigging equipment should be on your checklist.

Ready to revolutionize your lifting operations? Leap today with Hovair Systems! Our cutting-edge solutions are designed to cater to all your lifting needs, ensuring you stay ahead of the curve. Elevate your processes, boost safety, and enhance efficiency. Reach out to us today!

Industrial operations often involve intricate and complicated processes that require specialized equipment to ensure smooth functioning. A hidden champion among these essential tools is the turntable, specifically the industrial turntable.

In this blog, we will dive deep into the role of industrial turntables and elucidate their pivotal importance in various sectors.

At its core, an industrial turntable is a rotating platform that allows for the movement or rotation of an object placed upon it. Imagine manually turning a heavy car or an industrial-sized piece of machinery.

Exhausting, right? This is where the role of industrial turntables becomes clear. By providing a smooth rotation, these platforms ensure efficiency and safety in various operations.

The car turntable and vehicle turntable have revolutionized automotive displays and garages. Showrooms often use them to showcase the beauty of a car from all angles without the need for the viewer to move around.

In tight urban parking spaces or garages, a turntable can effortlessly rotate a car, eliminating the need for complicated multi-point turns. Not only does this increase convenience for drivers, but it also ensures safety by reducing potential accidents.

But the role of industrial turntables isn’t limited to just cars. From film and television sets, where large props or set pieces need to be rotated, to manufacturing sectors, where raw materials or products need to be turned – the applications are vast.

Industrial turntable systems play an integral role in ensuring that businesses run smoothly. They assist in maximizing the workspace, improving worker safety, and boosting efficiency in production lines.

What truly stands out is the ability of industrial turntable systems to optimize operations. In industries where precision and efficiency are paramount, these turntables minimize human intervention and reduce the chances of error.

They can be automated or manual, but in either case, they significantly improve operational flow. The role of industrial turntables in increasing efficiency can’t be emphasized enough.

Industries can achieve faster production times, better quality control, and enhanced operational experience with them.

One cannot discuss the role of industrial turntables without touching upon the safety aspect. They reduce the need for workers to engage in potentially hazardous activities like lifting heavy objects or making sharp turns with large machinery.

By simplifying these tasks, industrial turntables are pivotal in minimizing workplace accidents and ensuring workers can focus on their primary responsibilities without undue risks.

Elevate Your Operations with Hovair Systems

Elevate Your Operations with Hovair SystemsTo wrap up, the role of industrial turntables in various operations, from the automotive sector to manufacturing units, is both pivotal and transformative. They might not always be in the limelight, but their contribution to safety, efficiency, and operational excellence is undeniable.

Are you considering integrating industrial turntable systems into your operations? Don’t hesitate! Reach out to Hovair Systems today to explore how we can elevate your operational efficiency.

Remember, hidden gems like turntables often make the most significant difference in the industry world.

In the manufacturing and logistics world, bulk material handling plays a crucial role in the movement of materials such as chemicals, minerals, grains, and other dry products. The efficiency and safety of these operations can be improved by using advanced technologies designed for bulk material handling.

In this blog post, we will discuss some of the top technologies for bulk material handling and how they can help improve efficiency and safety in the industry.

Air-bearing systems are material handling systems that use a cushion of air to easily move heavy loads. The system comprises an air compressor, a supply hose, and a series of air bearings that support the load.

The air bearings are designed to minimize friction between the load and the surface it is being moved across. This technology allows for smooth and precise movement of heavy loads, reducing the risk of damage to both the product and the equipment used to move it.

Air pallets are another type of technology used in bulk material handling. They are similar to air-bearing systems, using air pressure to lift and move heavy loads. However, air pallets are designed to be used in areas with limited space for equipment or where traditional forklifts cannot operate.

This technology is particularly useful in industries such as pharmaceuticals, where cleanliness and sterility are essential.

Air beams are used for moving heavy loads of varying sizes and shapes, particularly for bulk material handling in the construction and manufacturing industries. An Air beam is a structure made of a flexible and durable material that inflates with air to form a beam.

The beam can then lift heavy loads and move them to the desired location. This technology is particularly useful for moving large and awkwardly shaped items that would be difficult to move using traditional material handling equipment.

Automated guided vehicles (AGVs) are another type of technology that is commonly used in bulk material handling. AGVs can be programmed to perform a variety of tasks, such as transporting materials between different areas of a warehouse or manufacturing facility. This technology reduces the need for human intervention in material handling tasks, improving efficiency and reducing the risk of accidents.

In conclusion, the use of advanced technologies in bulk material handling is essential for improving efficiency and safety in the industry. That’s why you should get in touch with Hovair Systems, a leading provider of material handling equipment. We offer a wide range of heavy load moving equipment. Contact us today and learn all about our technologies for bulk material handling.

Regarding modern equipment and its capabilities, the benefits of air bearings stand out prominently. A quick search for air bearings products online will give you an idea of the immense popularity and demand these products have gained.

But what exactly makes them so special? Discover the transformative impact of air bearings on load handling and how you might overlook a significant improvement to your operations.

At its core, an air bearing is a non-contacting system where a thin air film is used to carry a load. This might sound deceptively simple, but the genius is in the implementation.

When you use air-bearing kits, you’re essentially replacing traditional contact bearings (like ball or roller bearings) with a cushion of air. This dramatically reduces friction, wear, and the need for lubrication.

One of the key benefits of air bearings is their ability to handle both delicate and substantial loads with equal ease. Imagine having a vinyl record on an air-bearing turntable. The uniform air distribution ensures that the record is neither scratched nor damaged.

Now scale this up, and think about heavy machinery. The same principle applies: an air-bearing moving system can distribute the weight of massive objects, preventing any damage to the floor or the object itself.

But the advantages don’t just end at damage prevention. Air bearings offer a far superior level of precision. When there’s no contact and no friction, movements become smoother, allowing for higher accuracy in positioning and handling.

There’s no denying that the upfront investment for air-bearing kits might seem more compared to traditional systems. However, when you factor in the reduced maintenance costs, longer lifespan, and increased efficiency, the return on investment becomes clear.

Moreover, sourcing air bearings products online has always been challenging. With many options and specifications, you can find the perfect fit for your requirements with just a few clicks.

In today’s world, there’s a growing emphasis on green technology and sustainable practices. Air bearings fall perfectly into this category.

The reduced friction and wear mean fewer parts replacements and, consequently, less waste. Additionally, with no need for lubrication, there’s a marked decrease in the environmental footprint of your operations.

The future of efficient, precise, and sustainable load handling lies in the embrace of technologies like air bearings. As industries evolve, so do their demands, and the benefits of air bearings are poised to meet these requirements head-on.

The benefits of air bearings aren’t just limited to superior load handling. From the delicate turn of an air-bearing turntable to the robust might of air-bearing moving systems, these products promise a future of efficient, precise, and sustainable operations.

And with an abundance of air bearings products online, integrating them into your operations is easier than ever. Ready to elevate your load-handling game? Hovair Systems is here to guide you every step of the way.

Manual handling is a task that we all perform in our daily lives. It is a common cause of workplace injuries and can result in serious musculoskeletal disorders if done improperly. It is essential to understand the proper techniques and safety measures to prevent injuries. In this blog, we will discuss some effective ways to improve your manual handling technique.

Planning is essential when performing manual handling tasks. Assess the weight, size, and shape of the object you need to lift. Make sure the path is clear, and there are no potential hazards. Identifying the best way to lift the object and the available space to maneuver it will prevent injuries.

Using proper lifting techniques is crucial to avoid injuries. Keep your feet shoulder-width apart, and bend your knees instead of your back. Keep the object close to your body and use your leg muscles to push yourself up instead of jerking movements. If you need to change direction, pivot your feet and not your back.

Taking regular breaks is essential when performing manual handling tasks. This helps prevent fatigue and reduces the risk of injury. Taking a break every 30 minutes and stretching your body can prevent stiffness.

Wearing the proper gear is crucial when performing manual handling tasks. Wear comfortable, supportive footwear with a non-slip sole. Gloves can help improve your grip and protect your hands. If you need to lift heavy objects frequently, consider wearing a back support belt.

Maintaining good posture is crucial when lifting heavy objects. Keep your back straight, your shoulders back, and your feet shoulder-width apart. Bend your knees, not your waist, and keep the object close to your body. This will help distribute the weight evenly and reduce the strain on your back.

In conclusion, improving your manual handling technique is crucial to prevent injuries. Hovair Systems can help you improve your manual handling technique with our range of lifting and moving equipment.

We offer a wide range of air-bearing systems that are designed to reduce the weight of the load and make manual handling easier and safer. Our air-bearing systems can be used to lift, move and position heavy loads with minimal effort. Get in touch with us today and let us take your material handling to the next level.

The aerospace industry requires reliable equipment to handle materials in space vehicles. Pneumatic material handling equipment is a viable solution for the spacecraft industry, providing numerous benefits over traditional mechanical systems. In this article, we will explore the benefits of pneumatic material handling equipment for the spacecraft industry.

One of the significant advantages of pneumatic material handling equipment is that it is lightweight and requires minimal space. Pneumatic systems do not require bulky mechanical components, such as motors and gears, making them ideal for use in the confined spaces of spacecraft.

Furthermore, the reduced weight of pneumatic systems can significantly reduce the overall weight of a spacecraft, making it more fuel-efficient and cost-effective.

Safety is a top priority in the aerospace industry, and pneumatic material handling equipment offers several safety advantages. Unlike mechanical systems, pneumatic systems do not have exposed moving parts, reducing the risk of injury or damage to equipment.

Additionally, pneumatic systems can operate in hazardous environments, such as high temperatures or vacuum environments, without exposing personnel to dangerous conditions.

Pneumatic material handling equipment is highly energy-efficient, requiring only compressed air to operate. This energy efficiency can lead to significant savings over time, as less energy is required to power the equipment.

Moreover, the reduced energy requirements of pneumatic systems can help extend the life of a spacecraft’s power systems, increasing its overall lifespan and reducing the need for maintenance.

Pneumatic material handling equipment is easy to operate, with simple controls that are easy to learn and use. This ease of use can reduce the training requirements for personnel and can lead to more efficient operations. Additionally, the simplicity of pneumatic systems means that they are less likely to experience mechanical failure, reducing downtime and maintenance requirements.

Pneumatic material handling equipment is highly versatile, with a range of applications in the spacecraft industry. Pneumatic systems can be used for lifting, positioning, and transporting a variety of materials, including fragile or sensitive equipment. Also, pneumatic systems can be customized to meet specific spacecraft requirements, making them flexible and adaptable solutions for any application.

If you or someone you know is looking for material handling equipment, then Hovair Systems is your best option for it. We are one of the leading providers of material handling equipment, offering high-quality products at affordable pricing. Our wide range of products includes air pallets, air skids, air skates, and a lot more. Contact us today and learn more about our products.