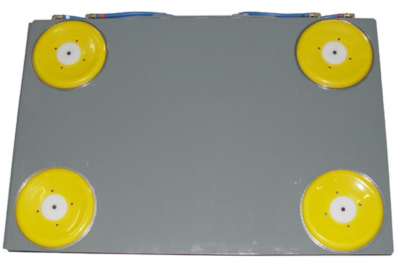

An air pallet is another type of aluminum transporter. These are the ideal material handling tools for usage in warehouses and other settings of the same kind. Continue reading “Air Pallets and Skids: Lightweight Solutions for Heavy Load Moving”

Month: July 2023

Heavy Load Handling: Essential Tips and Techniques for Safe and Efficient Moving

Heavy load handling is a significant aspect of the manufacturing and warehousing processes. A wide variety of tools, lifting devices, storage devices, and other material handling

equipment is needed for this. The more productive the workplace will be, the easier lifting and moving objects is.

Hovair Systems, the top US ergonomic material handling equipment producer, provides the key advice and methods for a safe and effective moving. These suggestions will simplify transporting large goods while lowering the dangers of damage and injury. Find out by reading on.

Essential Tips and Techniques for Safe and Efficient Moving

These tips and techniques will ensure fewer injuries and lost workdays and boost employee motivation and compliance.

Plan the Course of Movement

Employers should consider the load, height, and distances involved in the task. They must consider where the load needs to be picked from, where it will be placed, and the frequency of the activity. It is best not to lift more than what the employee can manage.

Decide on Heavy Load That Can Be Lifted Safely

Employees must make a good call on what they know they can safely move. Heavy load handling is not for everyone. Only if the employee can lift the loan, understands the nature of the load, and is well versed with the environmental conditions and training should they be allowed to lift.

Identify Ways of Reducing the Risk

Employees must ensure that the heavy load is lifted from one place. Perhaps they can avoid it or ask someone else for help if it is at a great distance. If the employee can identify lifting aids to help them complete the task, it would be a great way to handle the situation.

If Need Be, Re-Arrange Tasks

It is best to rearrange tasks that the employee thinks are too much for him. Or, in some cases, they can just avoid lifting it and complete a smaller load. Employees might be able to pull instead of push or try and break up the distance between the moving points for ease.

Use Safe Lifting Techniques

Maintaining a steady stance and excellent posture, keeping the weight as near the body as possible, utilizing the legs and feet (rather than the back), keeping the head up, avoiding twisting, and lifting smoothly are all examples of safe lifting practices.

According to OSHA, you should never use lifting or rigging equipment with weights over their rated capacities. Doing this is a severe safety risk for the workers and may cause costly project delays and damage

Contact Hovair Systems for Heavy Load Handling

Contact Hovair Systems for Heavy Load Handling

You can find various moving equipment and tools at Hovair Systems, including air bearings, hydraulic lifting jacks, rigging equipment, aluminum transporters, and many more. We provide heavy load-handling systems, load-leveling airbags, industrial turntables, and more. Explore our complete range or contact us today.

Our representatives can help you streamline top-quality automobile and industrial turntables and other pneumatic lifting and rigging equipment. Schedule a consultation to speak to our qualified experts.

Air Bearing Modules Vs. Lift Decks: Which Is The Best Solution For Your Business?

Air bearings and lift decks are incredible solutions for heavy load moving and lifting or transporting heavy machinery, equipment, and other materials. You may be wondering what the difference between the two is and which is the best solution for your own business. Well, regarding the question of air-bearing modules vs. lift decks, you should note that both the lifting solutions are pretty much the same. Whether you call them air-bearing modules, air casters, or lift decks, they all perform the same function. Continue reading “Air Bearing Modules Vs. Lift Decks: Which Is The Best Solution For Your Business?”

The Evolution of Material Handling Equipment: From Wheelbarrows to Air Casters

There have been great advancements in the manual material handling equipment area. The movement of material from one place to another has evolved to meet modern expectations and allow workers to work efficiently. Continue reading “The Evolution of Material Handling Equipment: From Wheelbarrows to Air Casters”

Understanding the Benefits of Ergonomic Equipment in the Workplace

Investing in ergonomics equipment is key to reducing workers’ health care and compensation costs while increasing productivity. Continue reading “Understanding the Benefits of Ergonomic Equipment in the Workplace”

Contact Hovair Systems for Heavy Load Handling

Contact Hovair Systems for Heavy Load Handling