The origins of cargo hoisting can be traced back to the Egyptian Pyramids, when employees manually carried huge burdens. Countless people died and were injured throughout that period. Nevertheless, there are a huge proportion of occupational fatalities caused by conventional load handling in today’s technological age. The usage of pneumatic hoisting gear is a cost-effective way for businesses to minimize workplace injuries and increase output.

A lot of reasons have contributed to the swift and global spread of industrialization over the last decades. Air compressors are one major element and innovation that has succeeded in changing various sectors. Air compressors have allowed commercial firms to create things at speeds that might normally be difficult to achieve with human hands.

As per the Markets & Markets, the worldwide air compressor industry is forecasted to increase at over 30%. According to Costowl, depending on the size and the manufacturer, an average air compressor can cost anywhere from $1,000-70,000. This post will review some of the elements that have contributed to the ubiquitous expansion and adoption of air compressors over the last year.

Take a look at this guide to understand the concept and working of compressed air tools along with their benefits

Understanding The Concept And Working Of Air Compressed Tools

Air compressors are the motors that drive mechanical equipment, which are the same items that make residential tasks simple. Putting up these compressors is typically easy, requiring only the connection of a pipe and a power cable. Maintaining the air pressure, regulating it with various appliances, and releasing the drain faucet after completing the task are all vital concerns.

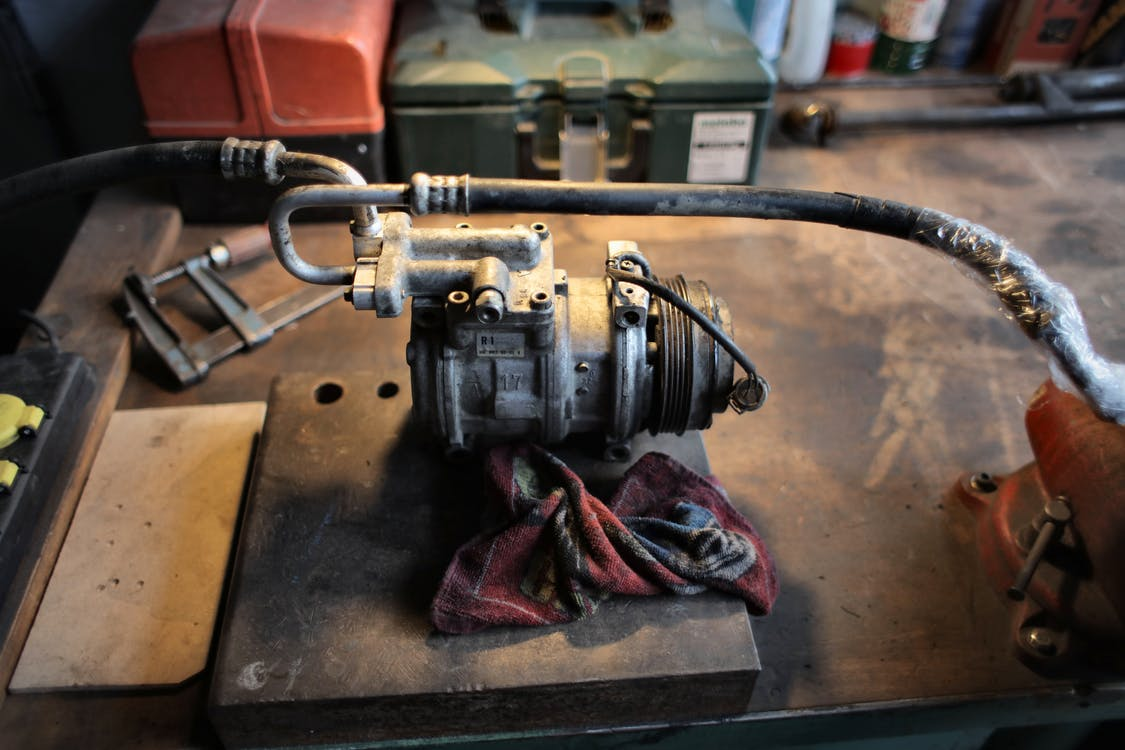

Air compressed tools operate on a simple notion: when the volume is reduced, the quantity of air pressure increases. The piston mechanism, which consists of a chamber, piston, throttle opening, crankshaft, and linking rod, is used to create this pressure. Based on the tools model, the air compressor is driven by either a mechatronic or a fuel engine.

Air compressed tools operate on a simple notion: when the volume is reduced, the quantity of air pressure increases. The piston mechanism, which consists of a chamber, piston, throttle opening, crankshaft, and linking rod, is used to create this pressure. Based on the tools model, the air compressor is driven by either a mechatronic or a fuel engine.

The input and output outlets are two holes at the apex of the cylinder, located on opposing sides. The input valve draws air in, forcing the piston downwards, while the output valve lets the pressurized air out. The piston motion generates vacuums within the chamber, resulting in a pressure gradient. This divergence pushes air into the piston through the input valve, where it’s compressed and deposited in the reservoir, allowing the process to continue and raise the compressed air within the piston once more.

What’s Driving The Change?

The emergence of air compressed tools is mostly due to two things. The first is the expansion of manufacturers around the world, particularly in emerging economies like the Middle East. The other motivation is the immense possibilities of this innovation, which is being recognized every year thanks to advances in air compressors.

Other elements that influence market patterns are divided into the following classifications:

Other elements that influence market patterns are divided into the following classifications:

1. Industrialization

The market growth for linear and motor-driven air compressed tools has been attributed to industrialization, particularly in emerging countries. Companies are increasingly dependent on air compressors in urban areas across Asia, South America, and Africa. China, South Africa, and India are currently some of the strongest marketplaces for air compressed tools. In the upcoming years, compressed air instruments are expected to drive mechanization in these nations.

2. Technological Innovation

2. Technological Innovation

Modern editions that give more output while using less power are the main factors pushing the air compressor industry forward. Suppliers are replacing outdated models with updated versions that are more efficient, save money, and are easier to use due to technological advancements.

3. Investments

The need for air compressed tools is increasing as smaller countries make investments in the construction of production units. Companies understand the advantages of compressed air over power transformers, which is driving up their need in nations like India and China.

Types of Lubrication in Air Compressors

Lubrication is extremely important in compressed air tools upkeep. Valves are divided into two groups when it comes to the usage of oil as an emulsifier: oil-lubricated compressors and oil-free compressors. The cylinder assists in spraying oil onto the joints and sidewalls within the chamber; that’s why it’s often called “oil-flooded” lubrication. Oil-free compressors are already lubricated for a long time. While they are handier and demand less upkeep, they put more strain on the engine and generate a lot of rackets when in use.

How To Optimize Air Compressed Tools

The following are some ways to optimize your air compressed tools:

1. Inspect Regularly For Leaks

Leakage in the compressed air tools wastes20 to 30 percent of the energy it produces. Major breaches have a significant effect on the air compressor’s performance; the compressors need more pressure to work efficiently as a result of the leak. The requirement for additional pressure raises the expense of operating.

Defects also increase the expense of upkeep. Pipes, connectors, cylinders, pipe joints, fixtures, and swift disconnects are all common place to find them. When you have your air compressor maintained on a constant schedule, the professionals will look for defects and fix them before the problem escalates.

2. Avoid Overloading

Over-pressurizing your compressed air tools can compromise their performance. Maintain the suggested operating level to prevent over-burdening your device. Take note of your pressure transducers and choose high-quality compressor gear. Installing controllers to check pressure is beneficial. In this manner, you can reduce your loan while minimizing stress and strain.

3. Preventing Unexpected Pressure Changes

When compressed air goes straight from the pump output to the terminal destination, pressure decreases suddenly. To compensate for the rapid depressurization, operators typically increase the regulator or increase output pressure. As a result, the device uses more power.

4. Utilize Varied Renewable Resources and Air Supply Networks When Suitable

Rather than compressed air, you might need to use other air distribution technologies for advanced systems. Employing a filtration system can work better in some situations. An air blower can be used to help eliminate steam or debris.

5. Choose the Correct Lubricant

Employ a lubricant that suits the mechanical properties of the tool to get the most out of them. These lubricants must be kept safely and applied in the precise ratios to work at their optimum.

Advantages Of Air Compressed Tools

The following are some advantages of air compressed tools:

1. Ease of Use

Compressed air is used in air-powered machines for hauling and material handling. Heavy-duty mechanical engines are no longer required. These devices are smaller and sleeker. They have better aerodynamics than standard load-lifting devices.

The apparatus can be used for lengthy periods without exhausting the user. Their small size enables them to move hefty items in tight spaces. In limited places, manual labor is no longer required. You only need to connect it to the ventilation system, and you’re ready to go!

2. Durability

2. Durability

The integrity of pneumatic devices is streamlined. In comparison to electromechanical or hydroelectric gear, the device has a reduced quantity of materials. This lowers the frequency of upkeep. If electrical devices fail, there is a substantial chance of electrostatic discharge.

These dangers are reduced with air-powered machines. Air-powered gear is preferred in manufacturing units that cope with flammable gases and porous structures because it removes the risk of electrification.

3. Cost-Effective Option

They use less energy. Refurbished components are easily available and significantly more economical than those for traditional equipment. Repeatedly operating mechanical components wear rapidly and demand periodic upkeep. As pneumatic technology contains static components, it does not require frequent maintenance.

4. Productivity Improvements

4. Productivity Improvements

Their simplicity, effectiveness, and flexibility allow difficult procedures to be executed quickly. This is due to their simple operation. They’re beneficial for manufacturing sectors looking to increase manufacturing capacity while reducing costs.

5. Exceptional Operational Capability

When compared to electromagnetic machines, pneumatic hoisting gear provides more functional efficiency. Their strong torque allows them to work more quickly. They can regulate the intensity. The user can change the pace to suit the needs of the operation.

6. A Flexible Alternative For Any Situation

Air devices can automatically adjust to any surroundings if there’s no energy to charge the device. The flexibility of pressurized gas as a source of energy is overshadowed by other forms of energy such as DC power, fossil fuel, and highly-flammable petroleum. In areas like an oilfield or underground, compressed air can be kept in canisters and employed as a propulsion system for air equipment.

While air-lines can be a concern in specific cases, compressed air’s dependability as a propulsion system makes pressurized air equipment the right candidate for a diverse array of projects, whether employing a solid electrical hookup to operate a compressor or employing compressed air reservoirs.

7. Prevention Of Mishaps

Since air tools can be used in situations containing dampness, semiconductor polymers, and even hazardous and combustible compounds, they are safer than electromagnetic devices. Working with electrical instruments in these kinds of settings can be dangerous. While air tools don’t utilize electricity to work, there’s less chance of combustion or electrocution if cables are compromised or subjected. This offers protection for the user.

Pneumatic instruments can tolerate more contaminants than electrical equipment, including dirt, radiation, and moisture. These components can affect electromagnetic devices, making them degrade over time, leading to premature machine breakdowns. Moreover, unlike conventional equipment, air tools have a low danger of underperforming due to the high temperature, short-circuiting, or electrical hazards.

Select a Noise-Limiting Tool

Make certain you select a silent compressed air tool. Consider putting it on a rubber pad to lessen loudness and reduce disturbances. If you utilize oil-flooded pumps, always remember to monitor their fluid levels periodically to ensure that they are not drying out. Furthermore, polish the joints you’re utilizing and make it well-lubricated to guarantee that it lasts a long time and doesn’t make a lot of whirring beeping.

Get In Touch With One Of The Most Trustworthy Compressed Air Tools Service Providers In Seattle

Regardless of your industry, you can use air-compressed tools to improve your industrial performance. If you want to get air-compressed tools for your specific industrial needs, you should consult an experienced and reputable firm before investing in air-compressed tools.

If you’re in search of a team that can help you in manufacturing high-quality air-compressed tools to tackle construction projects for your business, then Hovair Systems is the one for you. It’s important to choose the right person for the job if you want to save your time, money, and efforts.

Hovair Systems has established itself as a prominent warehouse equipment provider, providing air casters, air bearings, and other rigging equipment to well-reputed firms. Primarily based on pneumatics, the company’s range of handling products is designed to streamline the load transportation process. The company’s extensive experience of over 50 years has helped to develop a sound understanding of the warehousing needs of modern industries.

Hovair Systems design, build, and manufacture a wide range of industrial tools and material handling equipment, such as industrial turntables, heavy load handling systems, moving heavy loads, air beams, vehicle turntables, automated guided vehicles, heavy movers, air bearing modules, automated equipment for handling of heavy loads, air bearing kits, moving heavy machinery, and air compressor tools.

From vehicle turntables, lifting & rigging equipment, and industrial turntables to heavy load moving machines or other industrial materials handling equipment, they have solutions for all your material handling needs. The company is committed to helping clients automate their industrial processes. The company provides air-bearing services as well to the clients.

Hovair Systems is one of the best platforms among large and small industries for industrial turntable Systems, rigging equipment, lifting & rigging equipment, and durable air bearings. Hovair System’s products are renowned for reliability and effectiveness. Its clients include Lockheed Martin, Hewlett Packard, Boeing, Goodrich Aerospace, Siemens, Pilkington, and other well-known companies.

The company pays specific attention to the Process Hazard Analysis (PHA) requirements and strictly complies with the safety standards to ensure that the team and customers are safe and secure. You can get in touch with the company to learn about products that can help you in your construction projects.

2. Technological Innovation

2. Technological Innovation 2. Durability

2. Durability 4. Productivity Improvements

4. Productivity Improvements