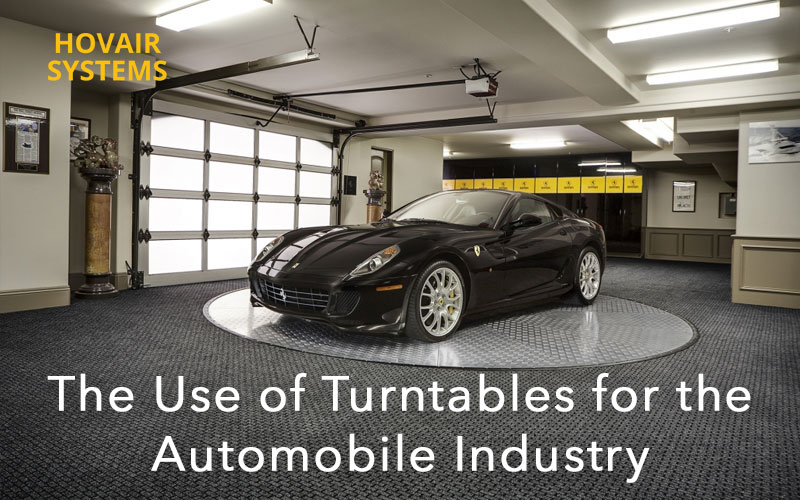

Within the automobile and exhibition industry, the value of vehicle turntables is unique. Being essentially a rotating platform, it is particularly useful within assembly units, showrooms, and exhibitions, as it enables the manual rotation of a vehicle. Offering a varied range of turntables for trucks, cars, the automobile industry, and specialty uses, Hovair produces state-of-the-art turntables.

These uniquely-built turntables that provide high capacity and stable rotating platforms are easily customizable. Rather than opting for a DIY car turntable, opting for a solid, durable, and reliable turntable is a better alternative. These turntables aren’t just appropriate for residential environments, but are also suitable for a commercial environment, making them the required apparatus for exhibiting or examining a vehicle. Built with a sturdy material, they are a cost-effective and lasting solution for car-enthusiasts and the automobile industry. With either the option of powering them through an electro-mechanical or air-bearing system, they are convenient to use.

- Easily installable into a driveway or garage using in-ground drive pits

- All components of pit ring construction are provided ahead of time for the contractor’s use

- The convenience and liberty of choosing between electro-mechanical powered installation or an air bearing system

- The liberty of choosing multiple-positions starts and stops

- Easy to use with high-safety, reliability and low maintenance

- Easily usable control panel for internal usage

- No need to turn into tight driveways or garage spaces

- Drawings supplied with each model for the contractor to use

Industrial & Specialty Turntables

The global demand for vehicles has risen exponentially in the past two decades. This has led the automobile industry to progress ahead and integrate technological advancements into their assembly units. Requiring various equipment for manufacturing a vehicle, the automobile industry specifically requires a turntable. Facilitating the material handling industry, Hovair Systems provides tailored turntables. With the requirement of each assembly unit varying according to what they manufacture, turntables are fine-tuned according to the differing requirements.

Through processes such as hot forming, lifting, and positioning, part identification, stamping, welding, work holding, thermo forming, and assembly, a manufacturer works towards completing a finished vehicle. By opting for a Hovair produced turntable, an automotive plant benefits and gains leverage of the following:

- Custom-built to the specifications and needs of the manufacturer

- Supplied for a permanent and fixed location or provided for convenient forklift truck moving

- Provided as either an electro-mechanically powered system or air-bearing powered

- Can easily be controlled through a foot pedal, hand pendant or pedestal panel

- Can easily rotate backward and forward with pre-set stopping points

- The availability of a variable control speed- up to 25 rpm

- Easily customizable into any size or shape- up to 24 feet in diameter

- Easily installable through using floor surface mounting bolts

- No need for excavation or digging for installation. It stands on the surface and bolt-mounts into position.

- Easily maintained with spares being easily available (however, rarely required)

- Highly-safe and easy to use – requires no specialized training for operating it

- The manufacturer incurs no additional costs for training or any safety hazards

Providing not just the equipment itself, Hovair Systems also offers installation service. Possessing the ability to adapt to a manufacturer’s requirements, Hovair works ingeniously in different industries. This is because, not just the automobile, but also the entertainment industry makes use of turntables, in instance for a carousel.

As a result of maneuverability being a big concern within restricted and cramped spaces, turntables play a critical role in making processes time-effective, cost-effective, and efficient. Varying in customized sizes and varying loading capacities, turntables are instrumental for optimized space utilization and decreased operating costs.