In the realm of material handling, efficiency, precision, and safety are paramount. Whether it’s a heavy load on a factory floor or a vehicle in need of repositioning, the choice of turntable can significantly impact operational success.

Today, we delve into the considerations between spring-operated and pneumatic turntables, crucial for industries relying on seamless movement.

At Hovair Systems, we understand the complexities of material handling, offering solutions that redefine efficiency and reliability. Read on to learn more.

Load Capacity:

Spring-Operated:

These turntables are engineered to efficiently handle moderate loads. The spring mechanism provides the necessary force to rotate the platform, ensuring smooth operation without compromising on safety. For industries dealing with relatively lighter materials or products, spring-operated turntables offer a cost-effective solution without sacrificing performance.

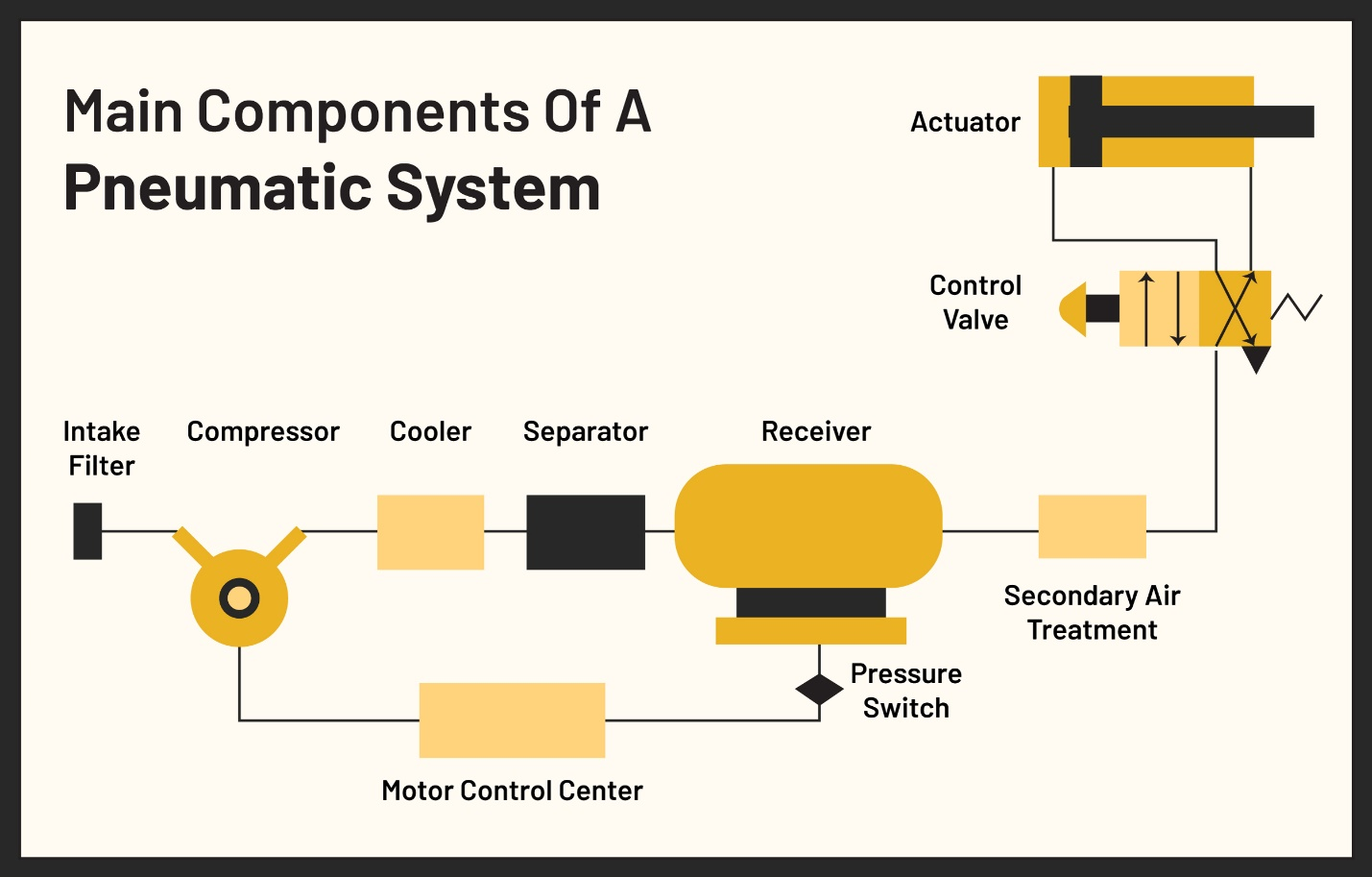

Pneumatic:

In contrast, pneumatic turntables boast higher load capacities, making them suitable for handling heavier materials or vehicles. By harnessing the power of compressed air, these turntables can effortlessly rotate substantial loads with precision and ease. This makes them ideal for industries where heavy-duty material handling is a primary concern, such as automotive manufacturing or logistics operations dealing with large and bulky items.

2. Precision Requirements:

Spring-Operated:

When it comes to precision, spring-operated turntables excel in providing consistent rotation within predefined parameters. The mechanical nature of the spring mechanism ensures reliable performance, allowing for predictable and repeatable movements. This makes them suitable for applications where consistent rotation is crucial, such as assembly lines or packaging operations.

Pneumatic:

Pneumatic turntables offer precise control over rotational speed and direction thanks to their advanced pneumatic systems. By adjusting the air pressure, operators can finely tune the movement of the turntable, making it ideal for delicate maneuvers or tasks requiring intricate positioning. This level of precision is especially valuable in industries where accuracy is paramount, such as electronics manufacturing or medical device assembly.

3. Maintenance:

Spring-Operated:

One of the significant advantages of spring-operated turntables is their minimal maintenance requirements. With fewer components susceptible to wear and tear, these turntables offer reliable performance with minimal upkeep. This translates to reduced downtime and lower maintenance costs, making them a practical choice for businesses looking to optimize their operational efficiency.

While pneumatic turntables offer advanced capabilities, they require regular upkeep of air compressors and pneumatic components. However, advancements in technology have led to more robust and reliable pneumatic systems, minimizing maintenance needs and increasing overall reliability. Despite the need for periodic maintenance, the long-term benefits of pneumatic turntables, such as increased efficiency and reduced downtime, outweigh the associated upkeep costs.

4. Cost Considerations:

Spring-Operated:

Spring-operated turntables are often more affordable upfront due to their simpler design and lower installation costs. This makes them an attractive option for businesses operating within budget constraints or seeking cost-effective material handling solutions. Additionally, their minimal maintenance requirements contribute to long-term cost savings, further enhancing their appeal from a financial standpoint.

Pneumatic:

Although the initial investment for pneumatic turntables may be higher, the long-term savings can be realized through increased efficiency and reduced downtime. The advanced capabilities of pneumatic systems, such as precise control and higher load capacities, contribute to improved productivity and operational performance. While the upfront cost may pose a consideration for some businesses, the potential for long-term cost savings and operational benefits make pneumatic turntables a worthwhile investment.

For seamless material handling solutions tailored to your needs, explore Hovair Systems’ industrial turntable offerings and experience the difference in efficiency and reliability. Order now or browse our range of air-bearing turntables to elevate your operations to new heights.

5. Environmental Impact:

Spring-Operated

Spring-operated turntables are generally considered more environmentally friendly due to their lower energy consumption. With no reliance on external power sources, these turntables operate efficiently without contributing to carbon emissions or energy waste. This makes them a sustainable choice for businesses looking to reduce their environmental footprint and adhere to eco-friendly practices.

Pneumatic

While pneumatic turntables require energy for air compression, advancements in technology have made them more energy-efficient over time. By implementing energy-saving measures and optimizing system design, manufacturers have been able to minimize the environmental impact of pneumatic systems. Additionally, the versatility and performance benefits of pneumatic turntables can contribute to overall operational efficiency, further reducing environmental impact in the long run.

6. Versatility:

Spring-Operated

Spring-operated turntables are well-suited for standard applications with consistent load sizes and weights. Their reliable performance and straightforward operation make them suitable for a wide range of material handling tasks, from palletizing to product assembly. While they may lack the advanced features of pneumatic turntables, they offer practical solutions for businesses with simpler material handling needs.

Pneumatic

Pneumatic turntables offer greater versatility and are capable of handling a wide range of loads and applications with adjustable pressure controls. This flexibility allows for seamless adaptation to changing operational requirements, making them ideal for dynamic environments where versatility is key. Whether it’s adjusting for different load sizes or accommodating unique material handling challenges, pneumatic turntables offer the versatility needed to optimize operational efficiency and productivity.

7. Noise Levels:

Spring-Operated

Spring-operated turntables operate quietly, making them suitable for environments where noise is a concern. Their mechanical operation generates minimal noise, providing a conducive work environment for operators and employees. This makes them an ideal choice for industries where noise levels need to be kept to a minimum, such as food processing facilities or cleanroom environments.

Pneumatic

While pneumatic turntables may produce noise during operation, advancements in design have minimized sound levels significantly. By implementing noise-reducing features and optimizing system components, manufacturers have been able to mitigate the impact of noise on the work environment. While some noise may still be present, it is often within acceptable limits and can be further reduced with proper installation and maintenance practices.

8. Installation Requirements:

Spring-Operated

Spring-operated turntables typically require less space and simpler installation procedures compared to pneumatic turntables. Their compact design and straightforward installation process make them suitable for a wide range of industrial settings, from warehouses to production facilities. Additionally, their minimal infrastructure requirements contribute to faster deployment and reduced installation costs.

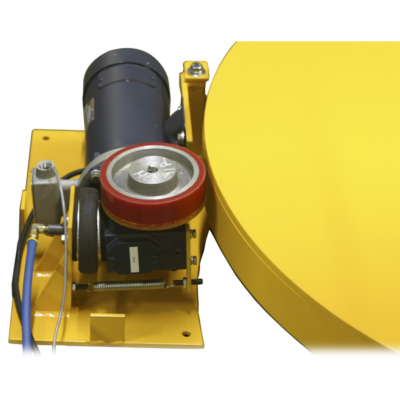

Pneumatic

Pneumatic turntables may require additional infrastructure for air compressors and distribution systems, depending on the specific application requirements. While this may increase installation complexity and upfront costs, it offers flexibility in placement and configuration. Pneumatic turntables can be integrated into existing pneumatic systems or standalone setups, providing adaptability to diverse operational environments.

In the dynamic landscape of material handling, the choice between spring-operated and pneumatic turntables hinges on various factors, including load capacity, precision requirements, maintenance, and cost considerations.

At Hovair Systems, we recognize the importance of selecting the right industrial turntable system for your specific needs. Our air-bearing turntables offer unparalleled efficiency, reliability, and precision, making them the ideal choice for industries seeking to optimize their material handling processes.

Explore our range of turntable solutions today and experience the difference in performance and productivity.