Heavy load handling is an integral part of every industry that requires materials to be moved or stored between locations. Reliable material handling equipment ensures faster, safer, and more efficient movement of loads through a range of processes, from manufacturing to storage, distribution, and delivery.

Given the importance of ergonomic heavy load handling systems, the material handling equipment sector has evolved invariably over the decades. Currently, we offer a range of specialty equipment to address various material and load-handling needs across various industries.

However, this evolution of choices also presents a challenge in equipment selection. Investing in the wrong material handling equipment can be detrimental to the business as it lowers process efficiency, which can lead to significant losses. Luckily, you can rely on our team at Hovair Systems, who is equipped with over five decades of experience for guidance. Here are a few things to consider before moving ahead with the investment.

#1- Properties of Materials That Need to be Handled

Selecting the right equipment for moving heavy loads starts with analyzing the properties of the materials that are typically handled in your facility. List all the solid, gaseous, and liquid materials and highlight the dimensions, shapes, and weight of all the units.

Check whether any of the materials require special handling due to their fragile, sensitive, toxic, or corrosive nature. Considering factors like whether the material is environment-sensitive or perishable, for instance, helps shortlist possible equipment from the available range.

#2- The Space Where the Equipment Will be Operated

Some material handling solutions can create disruptions, especially if the space has low-ceiling floors that can prevent the use of certain equipment. Many more space-related factors can influence the choice of tools. These include additional regulatory norms or environmental protection and workers’ safety or whether the operations at your facility require manual, semi, or automated material handling systems.

#3- The Facility’s Structural Strength

When determining the most suitable material handling equipment for your facility, the structural strength is another important factor that needs special consideration. Assess the floor capacity and door and aisle size, and determine whether the structure can handle the operation and weight of the particular material handling equipment you’re thinking of investing in. If you’re considering ordering customized equipment, check whether the floor capacity and space allow for such modifications.

#4- Intended Operation

#4- Intended Operation

Identify all the operations your equipment will need to fulfill when handling loads. If the focus is on storing, then racks, pallets, shelving, and containers are ideal because frequent movement won’t be necessary. However, if the operation includes handling bulk materials, you’ll need equipment that’s easy to use, mobile, and efficient. If the operations at your facility require continuous material processing and movement, going for automated guided vehicle systems will be a better choice for saving efforts, time, and costs.

#5- Safety Compulsions

When workers have to constantly lift heavy materials, your business is vulnerable to workers’ compensation lawsuits or worse. Employers must legally comply with the duty of care standards, which means they must provide ergonomic equipment that meets compliance standards.

Training is also essential to ensure workers remain updated with the best practices to use the equipment safely and efficiently while getting the job done on time. It’s also a great way to prevent workplace injuries, equipment damage, maintenance and improve productivity.

#6- Material Handling Equipment Company

Material handling solutions that best fit your needs while maximizing employee productivity, operational efficiency, and safety require partnering with a reliable supplier that only deals with top-quality equipment. Hovair Systems not only possesses experience worth over five decades but also offers matchless after-sales service to support your growth and success.

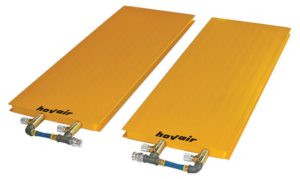

We’ve got a wide range of material handling equipment that can help complete even the most complex operations with safety and ease. These include durable air bearings, air caster, lifting & rigging equipment, air bearing kits, automated vehicle guiding systems, industrial turntables, automotive turntables, commercial turntables, and many other weight management solutions and heavy load management devices.

All of our specialty ergonomic equipment offers a safe alternative to the manual moving of heavy loads. Call or email us for more information about ergonomic equipment moving systems that will maximize worker safety with efficient tools that comply with safety regulations.

#4- Intended Operation

#4- Intended Operation