While casters may be a small part of the grand design of material handling equipment, they play an integral role in the cart’s safety and efficiency. While the caster technology may have experienced evolutionary changes in the last few decades, wheel casters still come with many complex challenges that can impact the company’s bottom line.

When casters fail, the entire design stops working. This means impaired ROI, unplanned downtime, workplace injuries, and loss of productivity. That’s why Hovair Systems has introduced air-based alternatives for moving heavy loads to prevent the risks of manual wheel caster operations while reducing frequent repair and maintenance or replacement costs. Let’s look at why wheel casters fail before looking for ways to avoid the hassle altogether.

Why Do Wheel Casters Fail?

Caster failure is often not the result of a manufacturing or design defect in the caster itself. Typically, the reason for wheel caster failure is that certain key considerations weren’t taken into account before going ahead with the investment. Here are the top four reasons wheel casters fail.

Reason #1- Capacity Overload

The primary reason for failure in the field is that the load capacity applied often exceeds the rated capacity of wheel casters. The pitfall can be avoided by evaluating the heaviest loads that may be moved at your facility.

Sometimes, bumpy or uneven floors can also lead to situations where three-wheeled carts cannot absorb the load like their four-wheeled counterparts. All castors come with a capacity rating, so overloading can cause them to fail.

You must calculate each wheel’s load capacity and divide the combined weight and maximum load by the number of wheel castors used. It’s recommended that you choose castors with a higher capacity than the calculation to allow for rocking, shocks, or poor flooring.

Reason #2- Impact Loading

The situation involves casters hitting a large bump or obstacle and experiencing the result of g-forces. It means that when a caster with a 100-pound load capacity hits a bump and experiences 6g, the impact would be as if the wheels are carrying 600-pounds at that moment.

Impact load, therefore, can cause a catastrophic caster failure because of g-forces that cause the cart to bear much higher loads than the capacity rating. In this scenario, shock-absorbing or spring-loaded casters can be helpful.

Reason #3- Wrong Bearings

Reason #3- Wrong Bearings

The same type of bearing won’t suit all. For instance, choosing bearings that aren’t suited to an application that experiences extreme humidity, temperatures, chemicals, or impact will increase the risk of premature caster failure.

Casters that aren’t well-suited for your facility’s environment can lead to corrosion, eventually increasing the risk of caster failure due to weakened components.

You must consider the bearing shape, material, and accessibility for maintenance to choose an appropriate caster cart for your application. However, in such situations, air casters prove the best choice because they’re made to thrive in diverse environmental conditions.

Reason #4- Brinelling

Brinelling refers to the wear or dent that’s pressed into a hard surface. When it comes to casters, brinelling occurs when the ball bearings in the swivel begin developing grooves in the hard cap.

Since the ball bearings play a critical role in the swiveling action, it leads to excess vibration, difficulty in cart direction, chattering, and improper operation, all leading to frustration and lowered productivity. This is because the swivel’s performance is impacted by brinelling when the swivel force is increased.

Observing the load capacity of the cart often helps avoid this type of wear by preventing the ball bearings from being pushed against the swivel head.

Reduce Changeover and Operational Costs by Choosing the Right Material Handling Solutions

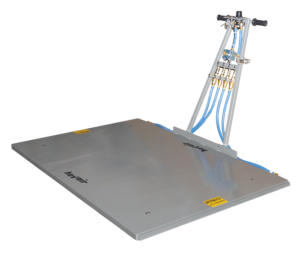

Material handling equipment changeovers can be costly and may impact your business operations. If you’re looking for ways to cut costs, introduce energy efficiency, and keep downtime to a minimum, browse Hovair’s pneumatic material handling equipment solutions.

Hovair is recognized as one of the leading platforms that manufacture durable air bearings, air caster, lifting & rigging equipment, air bearing kits, automated vehicle guiding systems, industrial turntables, automotive turntables, commercial turntables, and many other weight management solutions and heavy load management devices. All of their specialty ergonomic equipment offers a safe alternative to the manual moving of heavy loads.

Contact us for guidance on choosing the right heavy-load moving systems for your facility. Our specialists understand how different industry applications require unique moving systems for heavy loads.

Reason #3- Wrong Bearings

Reason #3- Wrong Bearings