In today’s rapidly evolving industrial landscape, innovation is the cornerstone of progress. With the advent of new technologies and material handling equipment, industrial operations are undergoing transformative changes that are redefining efficiency, precision, and scalability. Among the revolutionary solutions that are steering this transformation, lift decks and air bearings have emerged as key players.

The blend of creative engineering and modern technology has indeed sparked a transformative revolution that goes beyond the usual limits. This is leading to remarkable accomplishments in the industrial realm. Lift decks, designed cleverly to be versatile, are set to change how we move things up and down in industries. When combined with the effortless movement of air bearings, these innovations work together to solve longstanding challenges and push progress forward.

This comprehensive guide will navigate through the intricacies of these innovative industrial solutions, shedding light on their functionalities, advantages, and, most importantly, profound impact on various industrial sectors.

The Evolution of Industrial Innovation

Industrial innovation has been an integral driver of economic growth and technological advancement. Throughout history, industries have witnessed remarkable shifts from manual labor to mechanization, automation, and now the digital age.

This journey of innovation and creativity begins with the advent of mechanization during the late 18th century. This was when the Industrial Revolution marked a pivotal turning point as manual labor was gradually replaced by machinery powered by steam engines. Factories emerged, drastically increasing production capacity and altering the socioeconomic landscape.

Then the early 20th century witnessed the rise of mass production and the assembly line, a concept popularized by Henry Ford. This innovation led to the development of standardized processes and increased productivity, enabling the production of goods on an unprecedented scale.

The latter half of the 20th century saw the emergence of lean manufacturing principles and total quality management. These methodologies are aimed at minimizing waste, optimizing resource utilization, and ensuring consistently high product quality.

As environmental concerns gained prominence in the 21st century, industries shifted towards sustainable practices and long-lasting ergonomic equipment. Innovations in renewable energy, waste reduction, and eco-friendly materials emerged, reflecting a growing commitment to environmental responsibility.

In recent years, biotechnology and nanotechnology have taken center stage. These fields hold the promise of developing innovative materials, processes, and products with unprecedented precision and capabilities. The ongoing evolution witnesses the rise of customization through additive manufacturing (3D printing). This technology allows for rapid prototyping, reduced material waste, and the creation of intricate designs previously unattainable through traditional manufacturing methods.

Enter Lift Decks: Revolutionizing Vertical Movement

Lift decks have played a significant role in the ongoing industrial revolution, transforming the way materials are moved, stored, and accessed within various industrial settings. This unique and efficient material handling equipment has seamlessly integrated cutting-edge technology into traditional material handling processes, ushering in a new era of efficiency and adaptability.

Design and Functionality

Lift decks, also known as lift platforms or vertical conveyors, are mechanical systems designed to elevate heavy loads between different levels of a facility. They consist of a sturdy platform equipped with advanced hydraulic, pneumatic, or mechanical mechanisms. The design of a lift deck varies based on the specific requirements of the industry it serves. Some lift decks are built to handle massive loads in industrial warehouses, while others are designed for precision applications in cleanroom environments.

Operational Mechanism

The operational principle of a lift deck is relatively straightforward yet highly effective. This modern material handling equipment features a platform attached to a lifting mechanism that raises or lowers the load vertically. This can be achieved through hydraulic cylinders, scissor mechanisms, or cable-driven systems. Additionally, modern lift decks often incorporate sophisticated control systems, enabling operators to precisely position the platform and its cargo.

Advantages of Lift Decks

- Space Optimization: Lift decks make efficient use of available vertical space. They allow industries to maximize their floor area by utilizing unused overhead space for storage or material movement.

- Enhanced Efficiency: Lift decksstreamline material handling processes by reducing the need for manual labor and multiple handling steps. This leads to faster and smoother workflows, ultimately increasing overall productivity.

- Improved Safety: By minimizing the need for manual lifting and carrying of heavy items, lift decks contribute to a safer work environment. Workers are less prone to strain-related injuries, promoting employee well-being.

- Flexibility and Adaptability: Lift decksare highly adaptable and can be integrated into existing infrastructure with ease. They can be customized to accommodate various load sizes, shapes, and weight capacities, making them suitable for a wide range of industries.

- Precise Positioning: Lift decks enable precise control over the vertical movement of materials. This is especially advantageous in industries that require accurate positioning, such as manufacturing and assembly processes.

- Cost Savings: While the initial investment in lift decksmay be substantial, the long-term cost savings can be significant. Reduced labor requirements, increased throughput, and optimized space utilization contribute to a favorable return on investment.

- Versatility: Lift decks find applications across diverse industries, including manufacturing, logistics, automotive, construction, and more. Their versatility makes them an indispensable asset in various industrial contexts.

In simple words, lift decks have been an integral part of the industrial revolution by modernizing material handling practices and contributing to increased efficiency, safety, and adaptability. Their ability to optimize space utilization, enhance operational workflows, and provide precise positioning capabilities has made them essential material handling equipment for all industries. As industries continue to evolve and adapt to new challenges, lift decks remain a vital tool in their pursuit of progress and success.

Air Bearings: Effortless Mobility Redefined

Air bearings have emerged as yet another pivotal component in the ongoing industrial revolution, revolutionizing the way industrial processes operate today. These remarkable devices have seamlessly integrated advanced principles of fluid dynamics into industrial applications, reshaping the boundaries of what is achievable.

Manufacturing and Functionality

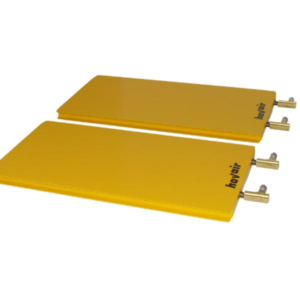

Air bearings, often referred to as aerostatic or air cushion bearings, operate on the principle of a thin air film created by a controlled flow of pressurized air. This film of air eliminates physical contact between the bearing and the surface it supports, resulting in near-frictionless movement. The core components of an air-bearing system include a porous bearing surface and a sophisticated control mechanism that regulates air pressure and distribution.

Operational Mechanism

When pressurized air is introduced between the bearing and the surface, it forms a cushion that lifts the load off the ground, allowing it to glide with minimal resistance. This characteristic makes air bearings highly suitable for applications that demand extremely precise and smooth movement, such as high-precision manufacturing, semiconductor production, and coordinate measuring machines (CMMs).

Advantages of Air Bearings

- Frictionless Movement: The absence of physical contact between the bearing and the surface results in virtually frictionless movement. This minimizes wear and tear, leading to extended equipment lifespan and reduced maintenance requirements.

- Precision and Accuracy: Air bearingsprovide exceptional precision and accuracy in positioning and motion control. This is crucial for applications that demand microscopic levels of precision, where even the slightest deviation can lead to compromised product quality.

- Vibration Isolation: Air bearings offer effective vibration isolation, preventing external vibrations from affecting the supported load. This is especially valuable in industries where stability and precision are paramount, such as optics and metrology.

- High Load Capacity: Despite their seemingly delicate nature, air bearingscan support substantial loads. This capacity, combined with their frictionless movement, enables the handling of heavy loads with minimal effort.

- Clean and Contaminant-Free: The air cushion created by air bearings prevents particles and contaminants from coming into contact with the bearing surface. This is advantageous in cleanroom environments where maintaining a sterile atmosphere is critical.

- Speed and Acceleration: Air bearingsallow for rapid accelerations and decelerations due to their low friction characteristics. This enhances operational efficiency and reduces cycle times.

- Reduced Energy Consumption: The absence of friction reduces energy consumption, making air bearingsan energy-efficient solution for various industrial applications.

In summary, air bearings have significantly contributed to the industrial revolution by redefining precision, efficiency, and versatility in various sectors. Their unique ability to provide frictionless movement, exceptional precision, and vibration isolation has led to transformative advancements in manufacturing, measurement, and other critical industrial processes. As industries continue to push the boundaries of innovation, air bearings stand as a testament to the remarkable potential of fluid dynamics and their role in shaping the future of industrialization.

The Symbiotic Impact on Industrial Operations

Air bearings and lift decks are two remarkable innovations in the realm of industrial technology and ergonomic equipment. Over time they have converged to create a symbiotic partnership that amplifies their individual capabilities, revolutionizing the way materials are moved and positioned within industrial operations.

Complementary Mechanisms

At first glance, air bearings and lift decks may seem distinct, but their synergy lies in their complementary mechanisms. Air bearings, with their ability to create a near-frictionless interface between surfaces, facilitate smooth and precise horizontal movement. On the other hand, lift decks excel in vertical movement, effortlessly raising or lowering heavy loads between different levels.

Vertical Movement Enhanced

When integrated, air bearings can enhance the vertical movement capabilities of lift decks. Traditionally, lift decks employ mechanical or hydraulic systems to control vertical motion, which may result in friction and vibration. By incorporating air bearings into the lift deck’s design, the vertical movement becomes even more seamless and controlled. The air cushion created by the air bearings reduces friction during elevation and descent, resulting in a smoother and quieter vertical motion.

Reduced Energy Consumption

The combination of air bearings and lift decks can lead to reduced energy consumption. The efficiency of air bearings in minimizing friction translates to lower power requirements during both horizontal and vertical movement. As a result, the overall energy expenditure for transporting heavy loads is significantly reduced, contributing to operational cost savings and environmental sustainability.

Enhanced Precision and Safety

Precision is a cornerstone of industrial operations, and the integration of air bearings with lift decks delivers an unprecedented level of accuracy. The frictionless movement provided by air bearings, coupled with the controlled vertical motion of lift decks, ensures the precise positioning of materials or equipment. This precision is crucial in industries that demand meticulous alignments, such as semiconductor manufacturing or aerospace assembly.

Moreover, the synergy between air bearings and lift decks enhances workplace safety. The reduced friction and controlled motion minimize the risk of sudden jolts or jerks during material handling. This, in turn, reduces the likelihood of accidents and injuries, promoting a safer working environment for employees.

Optimized Material Handling

Industries with intricate or delicate products benefit immensely from the integration of air bearings and lift decks. These combined technologies allow for the gentle and precise movement of sensitive materials, minimizing the risk of damage or contamination. From delicate electronics to fragile glassware, the partnership between air bearings and lift decks ensures meticulous handling throughout the entire vertical and horizontal transportation process.

The Future of Industrial Innovation

The future of industrial innovation holds a promise of unprecedented transformation and advancement, propelled by fast-paced technological progress. As we stand at the brink of a new era, we can expect to witness a blend of cutting-edge technologies that will reshape industries in ways we can scarcely imagine. Automation and artificial intelligence will intertwine to create smart factories and production systems that operate with unparalleled efficiency and autonomy.

Advanced robotics will revolutionize manufacturing processes, enhancing precision, speed, and adaptability. Nanotechnology will unlock new fields in materials science, enabling the creation of novel, lightweight, and high-performance materials that go beyond our wildest imaginations. Moreover, sustainable practices and green innovations will take center stage, guiding industries towards eco-friendly production methods.

Lift Decks and Air Bearings – Final Thoughts

Indeed, the collaboration between air bearings and lift decks represents a union of precision, efficiency, and safety in industrial operations. Their interaction not only optimizes material handling processes but also sets new standards for accuracy, energy efficiency, and workplace well-being.

Any industry that intends to survive and thrive in this fast-paced digital revolution needs to remain fully aware of the advanced technologies being introduced every now and then. If your company is on the hunt for reliable and durable material handling equipment, feel free to reach us at Hovair Systems. Our brand utilizes the power of compressed air to develop machine handling systems known to elevate efficiency and productivity. Introduce your company to ease and efficiency by contacting us today.