Have you ever moved from one house to another? If yes, then you must be aware of all the work that comes along with it. It involves moving heavy furniture, making sure that everything is moved safely, double-checking the fragile stuff, and a lot more. Now imagine the same, but it’s your business that is moving. The tasks just go multiplied by 100.

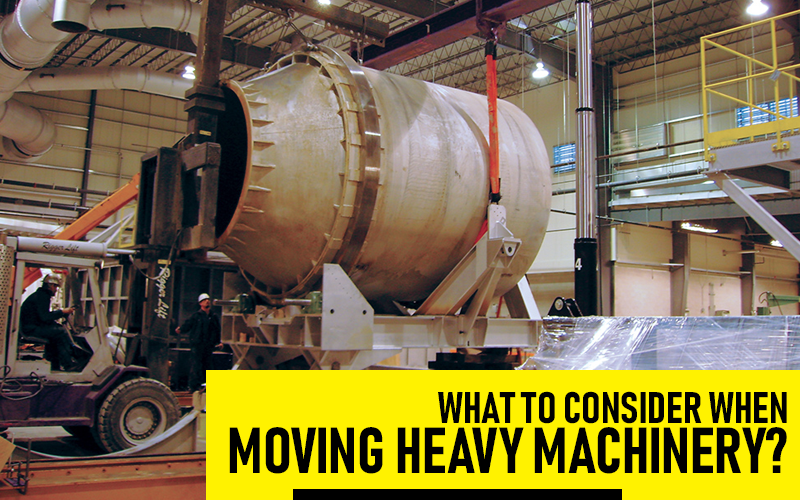

When you’re moving your business, is usually requires moving heavy machinery, and you can’t just throw all that stuff in a moving truck. You have to make sure that everything is moved carefully because these heavy machines could be your business’ most valuable and, at times, irreplaceable assets. Therefore, handling your heavy machinery adequately becomes a priority when moving your business.

If you’re moving your business for the first time, then you might consider the following things before moving your heavy machinery as you don’t want to take any chances.

Make a strategy

The first thing that you should do is make a strategy. You exactly need to know how things should be moving from one place to another. Make a plan a stick to it; what equipment goes in the first batch and goes in the later ones should already be decided by you. Make sure to transport the heaviest and most important machinery first, and what comes later will only make things easy.

Moving such heavy machinery will require heavy equipment movers, which you won’t find lying around. We advise that you contact moving companies as they will help you out with your transportation needs.

It is important to note that if you DIY everything, then there is a risk that you might end up mismanaging a lot of things. That’s why we advise you to contact a reputable moving company who are experts in moving heavy industrial machinery. Having people around who know what they’re doing is always a good idea, especially for first-time movers.

Time is money

Done with making a plan? Good, now let’s set some timelines for all the decided tasks. What you need to do is assign a time for every machine you move. The time should start the moment your machine is loaded in the truck until it is delivered to your location. Why are we emphasizing on time? Because most first-time movers make the mistake of allotting a single time slot for the entire transportation. This is where it all goes wrong; you could have many things that can up unexpectedly like a flat tire, traffic, or even setting up your machinery could take more time than you might’ve assumed. Therefore, assigning individual time slots for every machine movement gives you more flexibility.

Get to the details

If you think you’ve got it all figured out, then think again. After planning and allotting time for each transportation, you need to get into the details of how will you be moving your heavy machinery? The best way to do it by going through the manufacturer’s manual. It will guide you about everything that you should do so any and all accidents could be avoided while moving.

In the manual, you will find about how to safely remove the batteries, empty the engine fluids, secure loose parts, and other important things. Try to follow the manual as much as you can, as having an accident is the last thing you’d want.

Moving heavy machinery might also require special permits – this is where your transporter could help you. They are well aware of all the legal requirements and have the necessary Heavy Haul Equipment so your transportation could be without any trouble.

And lastly, you’ll need to cover all the sensitive parts of the machines. These parts are sensitive because there is a chance that they can be damaged by wind or rain. You need to remember that the heavy equipment will be transported in trucks, so the last you’d want is environmental damage.

We’re here for you

Transporting heavy machinery is a tough job, but with the right people, it becomes less troublesome. If you’re looking to get machines or services that could help you in moving heavy machinery, then you’ve come to the right place as Hovair Systems is in this business for more than 50 years. We have all the needed equipment like industrial and car turntables as they will ensure that you have a smooth machine moving experience.