Last Saturday marked the 50th anniversary of the Apollo 11 moon landing. To commemorate this achievement in human events, we wanted to revisit our own contributions to space exploration. In this article we will see how our air handling dolly aided NASA in the Space Shuttle program.

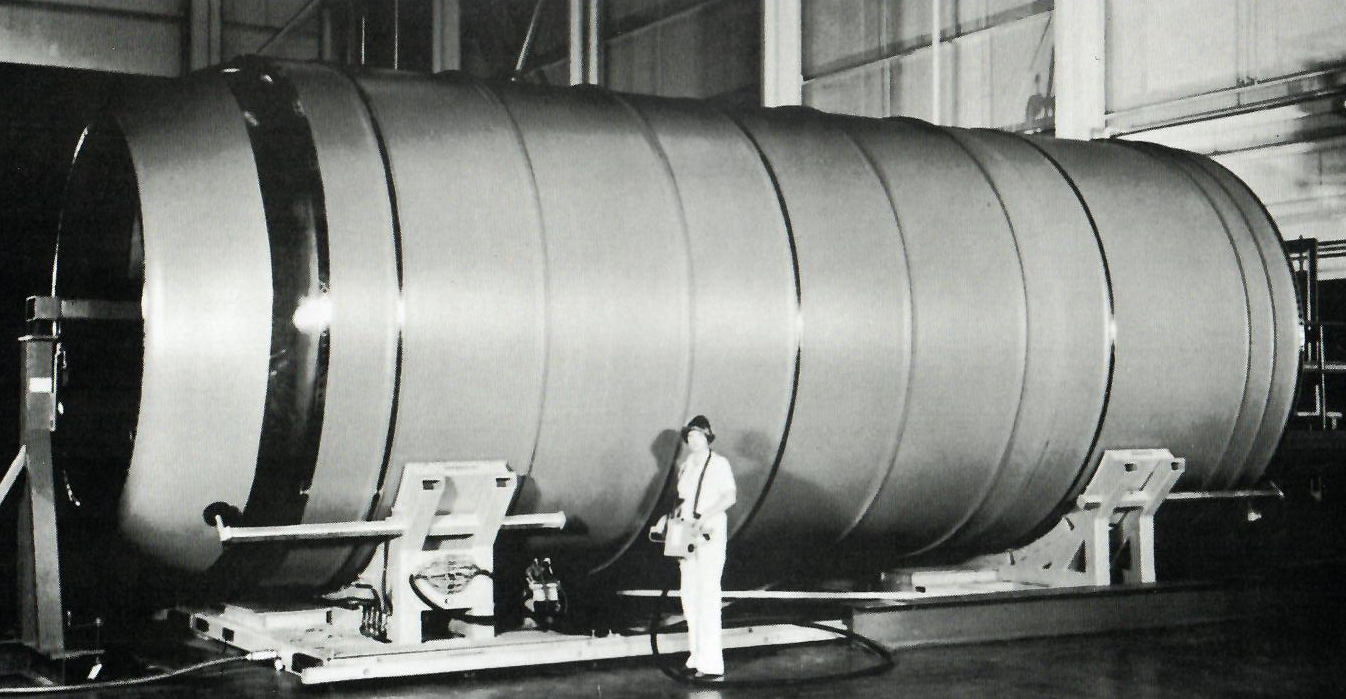

Hovair Systems prides itself on providing heavy load moving solutions, and what better challenge to test that ability than with rocket assembly? In 1978 we designed a Rocket Motor Case Handling Dolly, which was used in the assembly of solid rocket motors.

This dolly had a 12 ft diameter, and a weight capacity of 70,000 lbs. Despite the mass of the fuel containment vessel, it is nearly weightless when cradled in the dolly. This effect is due to our air bearing systems, which use compressed air to lift a heavy object away from a surface. Underneath the vessel are a series of rubber pads that allow free movement of the rocket. The dolly itself rests on a set of air bearings, which allowed engineers to float the entire rig across the factory floor.

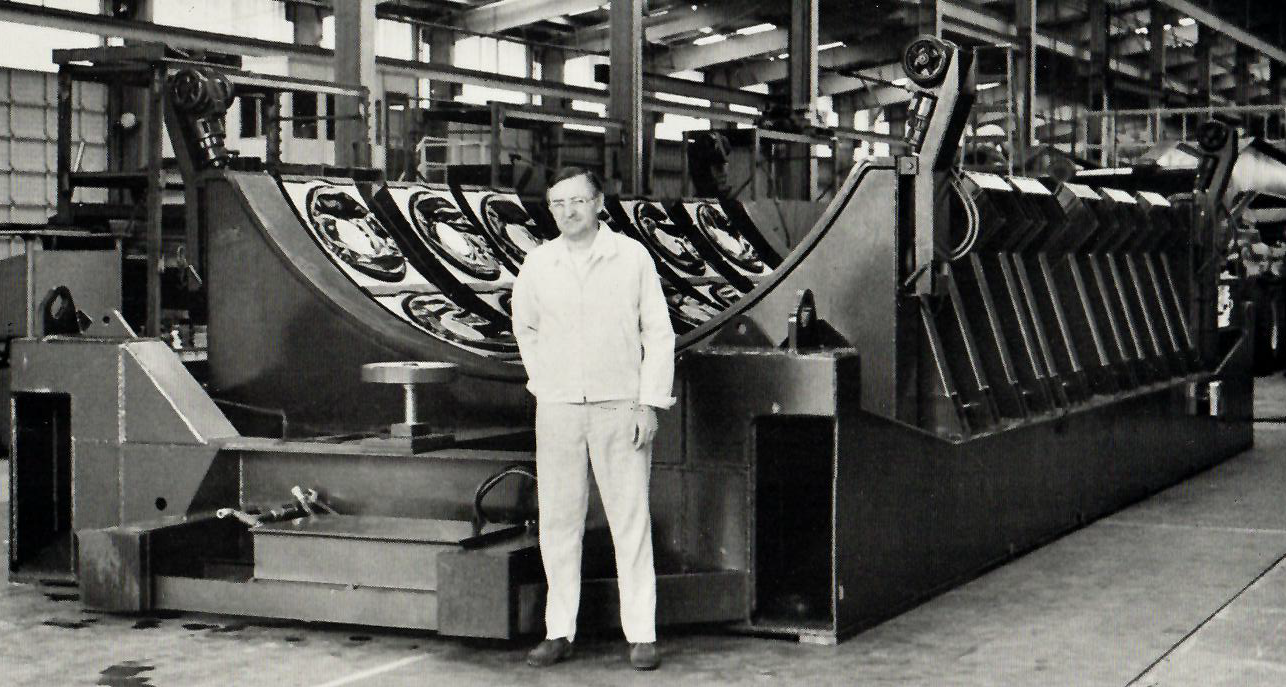

In this photograph you can see the record-shaped rubber pads on the air bearings. This is where compressed air escapes and creates an air-film seal between an object and a surface. The same technique is also applied beneath this dolly so it can move to other locations. This transporter was 13×36 feet, and could move Rocket Motor Case Segments weighing 360,000lbs.

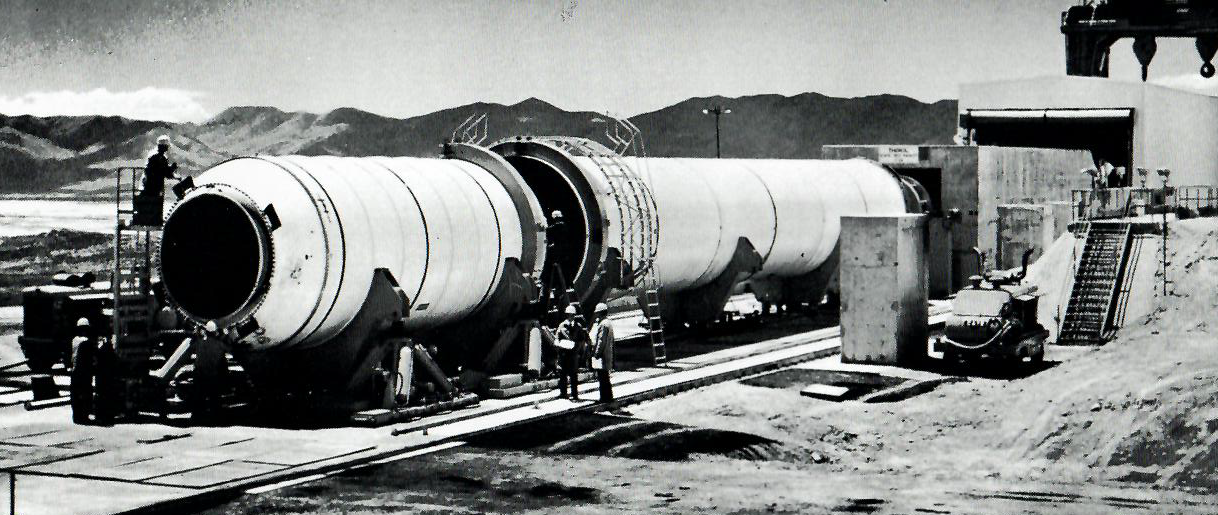

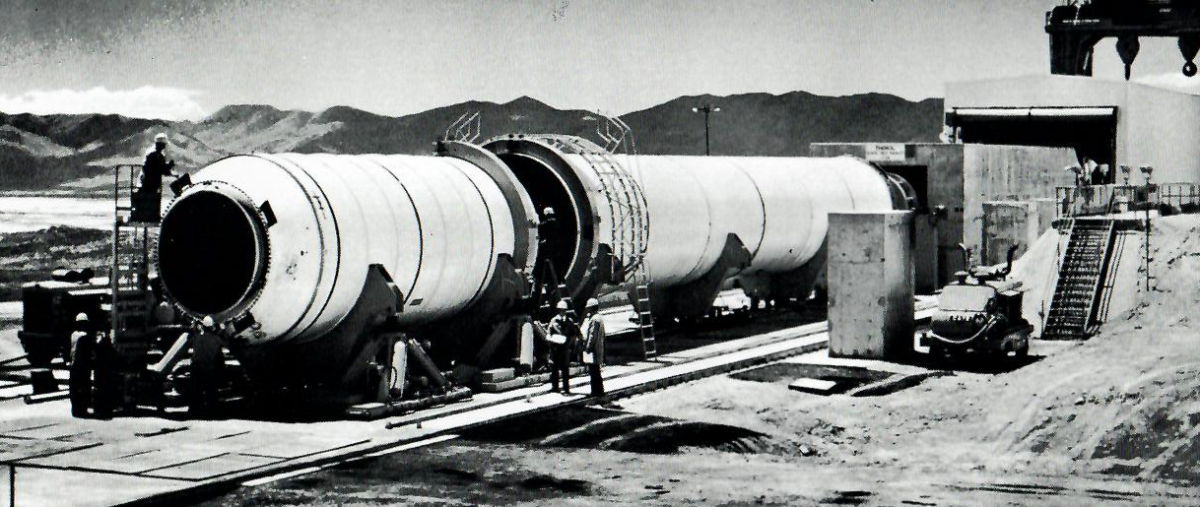

Here we see multiple units coming together in the assembly process. With machines this big there is no room for error. Hovair assembly equipment allowed for six degrees of freedom and provided movement within a few thousandths of an inch. This is just one example of the many industries we have helped throughout history. If you enjoyed this article, please leave a comment or share it with a friend. Remember to stay in touch for more news from Hovair Systems.

![Your Guide To Simplifying Heavy Machinery Transportation [Infographic]](https://www.hovair.com/wp-content/uploads/2018/11/Capture.jpg)