Warehouse managers have a lot they need to monitor, including directing equipment and inventory around the facility every day. The bulky furniture and inventory traveling from storage to shipment need to be handled properly. Even the workstations and storage cabinets may need frequent or occasional relocation to maintain the efficiency of your bustling warehouse.

Moving bulky loads is a challenging task. If you’re seeking information on improving efficiency in your facility when moving heavy loads, Hovair Systems is here to help. This guide will help you find all the answers. If you’ve got further questions, feel free to get in touch with the experts via a quick call. The key to efficiently moving bulky items is identifying the challenges you might face.

Challenges of Moving Heavy Loads

#1- Property Damage

#1- Property Damage

Moving heavy loads manually leaves the risk of extensive floor damage. A sudden drop can break the object and dent or crack the concrete, tile, or hardwood floor. Dragging bulky furniture can ruin the floor’s finish and cause scratches. Lifting by hand makes it harder to keep the furniture steady and off the ground, making floor damage more likely.

However, using the wrong material handling equipment is equally risky, with floors requiring special care. The added weight of the moving equipment is another challenge, as it can put a significant strain on the floor.

Trying to move heavy loads without considering the floor’s capabilities can damage the structural integrity. Therefore, when moving bulky items or heavy furniture, warehouse managers must know the correct way to alleviate strain and protect the workers.

#2- Safety Hazards and Ergonomic Injuries

Many bulky items are not just uncomfortable but also too heavy for manual handling. Anything heavier than an average adult’s weight isn’t practically a one-person moving job. If you think you can employ a team to get around this, rethink safety concerns. Straining is one of the leading causes of workplace injuries across many industries.

Muscle fatigue, shoulder pains, back strains, and musculoskeletal injuries are also possible when lifting lightweight objects incorrectly. The stress on discs, vertebrae, and muscles grows as the weight increases, creating higher injury chances and increasing absenteeism.

Besides straining, workers can also incur crushing injuries that lower employee morale and productivity. Additionally, you’ll need to deal with injury-related costs and workers’ compensation claims.

#3- Maneuvering Tight Spaces

Bulky furniture and heavy machinery sometimes need to be moved in jam-packed spaces. You must steer clear of permanent racks, equipment, furniture, and other fixed objects. Consider the object’s dimensions when planning to move bulky furniture. Plan the best route to reach point B from point A. account for lifted heights, doorways, and dimensions of the furniture you’re planning to move.

Best Material Handling Equipment to Move Heavy Loads

Hovair Systems offers many unique solutions to help your facility handle bulky inventory, industrial furniture, heavy machinery, and shipping containers. Moving heavy loads of all stripes becomes easier with specialized material handling equipment.

Hovair Systems offers many unique solutions to help your facility handle bulky inventory, industrial furniture, heavy machinery, and shipping containers. Moving heavy loads of all stripes becomes easier with specialized material handling equipment.

Air Skates

These are versatile furniture and heavy machinery movers comprising a flat surface with steel rollers. Using a lifting jack or forklift, operators can slowly set the furniture on the skates and wheel them to wherever they need to be.

Air skids are also helpful as they have a few additional features that make them more versatile as load-moving equipment. They can be moved 360 degrees, making it easier to steer the loads safely in multiple directions.

Lifting Jacks

These prove to be an ideal solution for bulky items that need to be operated at a certain level. Whether the loads need constant level checking or scaffolding, Hovair Systems’ air-lifting jacks are helpful in several applications. They make leveling, adjusting, and lifting easier and can be securely mounted onto air bearings for greater distance coverage and flexibility. The tool is easy to use and allows direct moving of the load from the air-lift units.

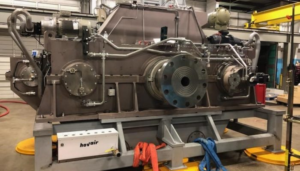

Automated Guided Vehicle Systems

Automated Guided Vehicle Systems

Automated guided vehicle systems are generally made from several units rather than a single piece of equipment. Automated conveyor systems, robotic delivery systems, and automated guided vehicles are common in warehouses across several industries. These systems are especially helpful as they eliminate the human element, making the entire process exceptionally efficient.

Air Bearings

Air bearings are ideal for lifting heavy loads with uneven weight distribution. They’re an easier and safer alternative and utilize compressed air to generate continuous airflow to inflate the components.

The heavy load floats across the surface when friction is created between both surfaces without requiring much manual effort. The adaptable positioning helps lift loads effortlessly over the thin cushion of air.

Air bearings allow the easy moving of bulky loads while preventing any potential problems. They’re perfect for areas with limited space or spaces that require spark-free operations.

What Makes Manual Handling Hazardous?

Heavy Loads

Heavy Loads

Bulky furniture or other items in a facility can weigh from a few pounds to several hundred kilograms. On average, the maximum weight limit for a one-person move is less than 30 kgs, especially if it involves lifting and holding the object for longer durations. It can induce stress on the workers, leading to them suffering from back pains, muscle pulls, and crushing injuries.

Large Loads

One of the fundamental rules for lifting loads manually is keeping them close to the body. The workers will need to spread their arms widely for loads that are too broad. When this happens, they might not be able to exert as much force as they could’ve if their arms were held close. It can cause extensive muscle straining and reduced productivity in the warehouse.

Slippery Loads

Some loads are difficult to grasp, leading to sudden jerks and chances of slips. Even when workers use gloves to reduce the friction against slippery loads, it doesn’t provide full protection from crushing injuries, floor damage, and the item being lifted breaking upon falling. Air skids are a better way to minimize the applied effort and collision possibilities.

Unbalanced Loads

Handling unbalanced loads gets tricky, as holding their gravity center close to the body can be tough. Uneven loading can wear out muscles, inducing fatigue. Sudden jerks can cause the worker to stumble and fall, damaging the load and injuring himself.

What Makes Pneumatic Moving Equipment Better?

Manual heavy load moving is not feasible for industrial settings for several reasons. Even for residential furniture moving tasks, anyone who has experienced the hassles of rearranging or moving heavy furniture around their home would know how beneficial air-powered heavy load movers can be.

Manual heavy load moving is not feasible for industrial settings for several reasons. Even for residential furniture moving tasks, anyone who has experienced the hassles of rearranging or moving heavy furniture around their home would know how beneficial air-powered heavy load movers can be.

Even in warehouse settings, pneumatic ergonomic moving equipment can help transport heavy objects conveniently and safely to ensure your facility runs flawlessly while reducing labor costs and workplace injuries. There is a host of benefits to investing in heavy load handling systems. Let’s learn about a few of them below.

Benefit #1- Labor Efficiency

Replacing manual heavy load handling with ergonomic equipment is an excellent way to improve efficiency across your facility. Electric or hydraulic tools can be complicated to operate and maintain, requiring frequent repairs or replacements.

Lifting heavy furniture manually requires a lot of strength and can strain the employees. Workers will require frequent breaks to move it across a safe system without damaging the floor or the object being moved.

Hovair’s pneumatic equipment doesn’t need too many hands on board, hence boosting labor efficiency. You can reduce the number of employees as your staff is free to perform other tasks when using air-powered tools.

Benefit #2- Ease of Use

Moving heavy loads or bulky furniture is a dreaded task without proper equipment. Air caster material handling solutions have various features to make heavy load moving effortless. They’re available in a range of sizes, from equipment that’s large enough to be driven to something small enough to be hand-operated.

From hauling heavy loads to moving bulky products, there are several uses for these pieces of equipment for your warehouse. The omnidirectional feature creates a high degree of maneuverability, making it easier to glide heavy loads through aisles and doorways.

Benefit #3- Load Leveling

One common challenge that comes with moving heavy objects like furniture manually is that it’s difficult to keep the load level. Human error can lead to the floor or the door nicking. Maneuvering around obstacles in tight spaces is difficult when moving furniture by hand.

Since load leveling airbags lift the furniture from all ends, the object can maintain the required clearance level even when moving around obstacles or turning corners. This is beneficial in preventing parts from being damaged or falling off. When moving machinery or drums around the facility, pneumatic material handling equipment also helps prevent fluids from leaking.

Benefit #4- Versatility

Benefit #4- Versatility

Pneumatic load moving systems come in various sizes to accommodate many dimensions and applications. They can help move extra-long and extra-wide objects worth 1000s of pounds without physical strains or accidents.

You can move around objects with irregular shapes and sizes efficiently. Corrugated boxes, crates, containers, appliances, industrial cabinets, furniture, and specialty equipment can also be moved quickly and safely using Hovair’s heavy load moving tools.

Benefit #5- Lifting Capacity

Pneumatic tools are air powered and don’t rely on human strength. That’s why they can efficiently lift some of the bulkiest items in the facility quickly. You can use the lifting jack to lower or raise the heavy load or furniture into place.

Since the air bearings can be permanently mounted on the lifting jack, they’re ideal for scaffold settings with multiple levels. You can easily level the road according to the surface to transport it safely to another area in a single operation.

Hovair’s lifting jacks have the manual capacity to lower or heighten and lift loads with the help of a cranking handle. In addition, the valve allows airflow control, making the device easier to operate. You don’t need to invest in a separate jack or can use the existing forklifts for other tasks throughout the facility.

Benefit #6- Safe and Ergonomic Design

All the facility’s workers will appreciate that the pneumatic heavy load moving tools lower the chance of strains and injuries. Unless it’s in a gym, heavy lifting isn’t anyone’s favorite task. The ergonomic design of all equipment at Hovair Systems prevents overexertion or repetitive motion injuries.

The chances of your workers accidentally lifting from awkward positions or lifting more than they can handle are mitigated when you use ergonomic equipment. They will also not drop bulky furniture during transportation, increasing the overall safety of the floors, other objects, and workers

Shop Lifting & Rigging Equipment from Hovair Systems

If you think pneumatic load moving systems are what you need, browse Hovair’s material handling equipment solutions to find the type that best suits your facility. We proudly offer a range of heavy load handling systems at competitive pricing.

With a deep understanding of how heavy lifts work, our experts can assist you with many heavy load management solutions. These include lifting & rigging equipment, durable air bearings, industrial turntable systems, air casters, air skates, air beams, load leveling airbags, automobile turntables, commercial turntables, and many other heavy load carrier devices.

Regardless of the industry you operate in, we can provide you with practicable material handling solutions to increase your industrial productivity. As a highly reputable heavy load equipment designing company based in the US, we’re proud to admit that we have satisfied hundreds of customers for the past five decades in the industry.

Regardless of the industry you operate in, we can provide you with practicable material handling solutions to increase your industrial productivity. As a highly reputable heavy load equipment designing company based in the US, we’re proud to admit that we have satisfied hundreds of customers for the past five decades in the industry.

We’re dedicated to offering all our clients unmatched customer support, durable machinery and products, and consultancy based on their specific needs. We don’t compromise on quality which is why our portfolio of clients includes the likes of Pilkington, Hewlett-Packard, Lockheed Martin, Siemens, NASA, Goodrich Aerospace, and Boeing, among others. All our pneumatic solutions meet industry regulations and keep both the loads and workers safe and secure.

Schedule a consultation with us to speak to our qualified experts. We can work together to understand your facility’s unique needs as we walk you through the process of streamlining cutting-edge moving systems for heavy loads.

#1- Property Damage

#1- Property Damage Automated Guided Vehicle Systems

Automated Guided Vehicle Systems Heavy Loads

Heavy Loads Benefit #4- Versatility

Benefit #4- Versatility