The debate surrounding pneumatic and electrical tools has been raging for since some time, and while each tool has its advantages, one is clearly superior to the other. Personal preferences aside, pneumatic tools are the preferred choice in many industries such as construction, shipping, heavy-repair, material handling, and even aeronautics.

In this blog, we take a look at the functionality of both pneumatic and electrical tools to determine which ones are superior.

Maintenance

Pneumatic tools don’t have a large number of intricate parts inside of them and are thus more durable. Electric tools rely on a motor to operate which contains many moving parts including rotors, bearings, and brushers that demand frequent inspection. Since air-powered tools lack such features, they are more durable and easier to maintain.

Power Source

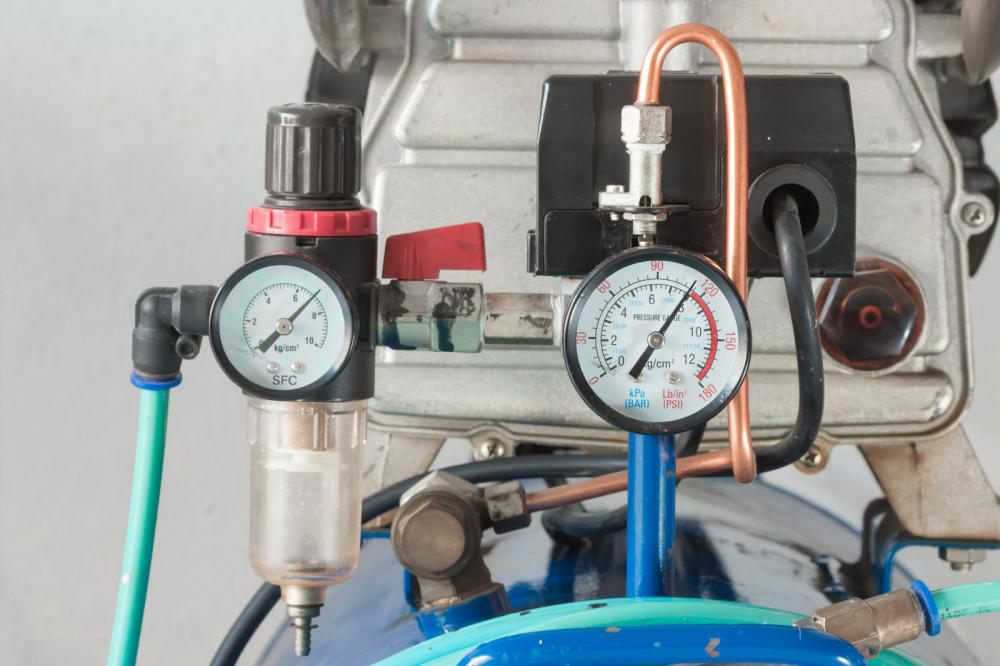

Unlike electrical tools, air-powered tools rely on a steady supply of compressed air to function whereas electrical tools rely on a constant supply of electricity. Such tools need to be kept near plug points to operate; otherwise they must be powered by rechargeable batteries. Pneumatic tools aren’t bound by such limitations and rely on less power to function leading to reduced energy costs.

Portability

Although air-powered tools are easier, lighter, and more comfortable to use, they too have their limitations including the need to carry around a heavy air compressor. However, unlike electrical tools that are limited by the length of the power cords, small air compressors can be carried by hand whereas the heavy ones are usually wheeled making them mobile and easy to move around.

Safety

Air tools are much safer to use since they don’t have electricity passing through them (It’s restricted within the air compressor’s motor).

Electrical tools, on the other hand, are dangerous to operate in wet conditions and pose a serious health hazard during malfunctioning. Also, electrical cords can be broken or exposed which increases the risk of electrocution.

Costs

The costs are difficult to compare because they vary according to the brand, quality, and features of each respective tool. However, pneumatic tools are less expensive than electrical ones if you already have an air compressor.

Even if the cost of pneumatic tools exceeds that of their electrical counterparts, the expenses are covered up in the long run due to increased output, lower operating costs, and the ability to use multiple air-powered tools on a single compressor.

Keeping all of these factors in mind, it can be concluded that the benefits of using pneumatic tools far outweigh those of electric-powered ones.

Hovair provides a wide range of quality pneumatic tools that includes machine rigging equipment, machine moving skates, and other tools used for moving heavy machinery. Contact us today for more information.