Industrial security plays a crucial role in the reputation of an industry. An industry that fails to comply with the health and safety standards doesn’t only risk the safety of its employees but also puts its reputation at stake. Installation of rigging equipment improves workplace ergonomics and reduces the risk of workplace incidents.

However, poor maintenance of rigging equipment can lead to unexpected downtime, costing you millions as you search for the spare parts! Regular maintenance prolongs the service span of your equipment and peaks their efficiency.

Here are some key tips to keep your rigging machinery humming along:

1. Create a Checklist

Create a checklist for monitoring. This would ease up the inspection process and allows you to maintain a record for each piece of machinery. You can keep an update on the working condition of your equipment, and identify any upcoming repairs.

2. Check for Lubrication

Workers often overlook this factor as they’re searching for major flaws in the machinery. Inspect your equipment for dry wires and ropes, and lubricate them on a regular basis. Avoid over-cleaning the wires, as this increases a chance of removing the lubricant.

3. Inspect For Loose Rivets and Bolts

Loose bolts are often overlooked and can cause a major workplace incident. They can cause the load to fall down, risking the lives of nearby workers. Any loose bolts should be immediately tightened to avoid such incidents.

4. Check for Signs of Wear

Industrial rigging equipment is exposed to wear due to continued usage. Although the machinery is known for its robustness, prolonged exposure to wear can cause it to break down. Check pad, rollers, and rubber tires for signs of wear and repair it to avoid downtime.

5. Avoid Overloading

Avoid exceeding the load limit of the equipment. Not only does it cause the machine to malfunction, but it can also impose a safety risk for the nearby workers.

6. Maintain a Balanced Load

Ensure that the load hook and upper suspension are properly aligned, forming a straight line. The load shouldn’t come in contact with the chain and hoist body. It’s important to know the swing range of the crane. The load should be placed in a balanced position without to avoid it from tipping over.

7. Hire Trained Personnel

Always hire a trained professional for operating industrial rigging equipment. They should have a prior experience in operating such machinery, conducting workshops for your employees, training them about troubleshooting, maintenance, and safety of the equipment.

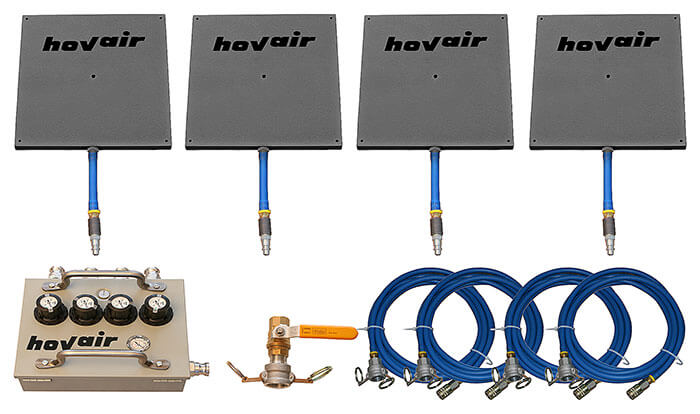

Hovair Systems provides a wide range of air powered products to handle  heavy machinery and loads. They can easily handle loads up to 100 tons and beyond.

heavy machinery and loads. They can easily handle loads up to 100 tons and beyond.

Get in touch with us today and add an extra dimension to your rigging capabilities!