Industrial turntables have become indispensable assets in modern manufacturing, providing a dynamic solution to various production challenges. Their ability to enhance efficiency, improve ergonomics, and contribute to quality control has positioned them as valuable tools across diverse industries.

Applications in Manufacturing

Assembly Processes

Industrial turntables are widely employed in assembly lines, facilitating the efficient assembly of products. Workers can rotate the turntable to access different components easily, reducing the need for unnecessary movements and improving overall ergonomics.

Material Handling

These turntables are utilized for material handling tasks, aiding in the easy and precise positioning of raw materials, work-in-progress components, or finished products. This is particularly beneficial in industries such as automotive manufacturing, where components need to be rotated and positioned accurately during the assembly process.

Painting and Coating

Industrial turntables are instrumental in painting and coating applications. They allow for controlled rotation of items, ensuring an even application of paint or coating substances. This is critical for achieving high-quality finishes in furniture manufacturing or automotive painting industries.

Quality Inspection

Turntables provide an efficient means for quality inspection processes. Products can be rotated for thorough examination, allowing inspectors to identify defects or imperfections from various angles. This contributes to maintaining high-quality standards in manufacturing.

Packaging

In the packaging industry, turntables are employed for the precise positioning of products during the packaging process. This aids in efficiently wrapping, sealing, and labeling items before they are ready for distribution.

Conveyor Systems Integration

Industrial turntables seamlessly integrate with conveyor systems, enhancing the flow of materials through a production facility. Items can be transferred between conveyors or production stations with a turntable’s assistance, optimizing the manufacturing process’s overall efficiency.

Benefits of Industrial Turntables in Manufacturing

Increased Efficiency

The ability to rotate products or materials with precision significantly improves efficiency in manufacturing processes. This is particularly evident in assembly lines, where workers can access different sides of a product without unnecessary movement.

Enhanced Ergonomics

Industrial turntables contribute to improved ergonomics by reducing the need for manual handling and awkward positioning. Workers can perform tasks more comfortably and with less strain on their bodies, leading to a safer and healthier work environment.

Quality Improvement

The ability to inspect products from multiple angles enhances the quality control process. Defects or irregularities that might be overlooked in a static position can be easily identified when the product is rotated on a turntable.

Space Optimization

In facilities with limited space, industrial turntables provide a space-efficient solution. They can be integrated into compact layouts, contributing to better space utilization and streamlined workflows.

Cost Savings

While the initial investment in industrial turntables is a consideration, the long-term benefits, including increased productivity and reduced manual labor requirements, often result in overall cost savings for manufacturing operations.

Flexibility and Adaptability

The versatility of industrial turntables allows manufacturers to adapt to varying production needs. With engineering expertise that stems from dominating the heavy load moving systems market for over five decades, Hovair Systems can help you streamline turntables with features tailored to your operations.

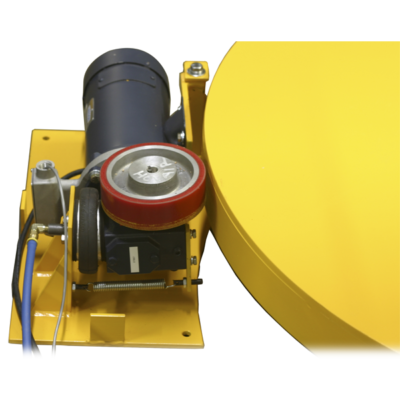

Order turntables with adjustable speed and rotation directions and motorized systems that facilitates continuous or intermittent rotation. The rotation can be adjusted to different speeds and directions, providing manufacturers with the flexibility needed for various production requirements.

Features like anti-slip materials, precision bearings, and varying load-carrying capacitiesmake turntables by Hovair Systems a valuable tool in dynamic manufacturing environments.

Order now to benefit from streamlined processes, increased productivity, and a competitive edge in an ever-evolving industrial landscape. Call now to request more information.