In the dynamic landscape of modern industry, the need for efficient heavy-load-handling systems has become paramount. From manufacturing plants to warehouses, logistics hubs to construction sites, the demand for seamless transportation and positioning of heavy loads has spurred innovation in tools, techniques, and equipment.

Among the diverse array of solutions available, one technology stands out for its versatility and effectiveness: air bearings. In this comprehensive blog, we’ll explore the tools, techniques, and advancements in heavy load handling, showcasing the products that are making a significant impact across various industries.

Advancements In Heavy Load Handling Systems

The world of heavy load handling systems is continually evolving, driven by the need for increased efficiency, precision, and safety in industrial operations. Let’s explore the latest advancements and innovations in heavy load handling technology, focusing on how these developments are bridging the gaps in modern industry.

1. Automation and Integration

One of the most significant advancements in heavy load handling systems is the integration of automation technology. Automation not only improves efficiency but also enhances safety by reducing the need for human intervention in potentially hazardous operations.

Automated heavy load handling systems are equipped with sensors, cameras, and advanced control algorithms that enable them to perform complex tasks with precision. For example, automated vehicle turntables and industrial turntables can seamlessly rotate heavy loads according to predefined patterns or in response to real-time feedback. This level of automation is especially valuable in industries where precision and repeatability are critical.

Furthermore, heavy-duty transporters have seen significant advancements in automation, allowing for the synchronized movement of multiple transporters to carry oversized loads with pinpoint accuracy. This capability is particularly beneficial in industries like shipbuilding, where moving massive ship components with precision is a complex challenge.

2. Remote Monitoring and Control

2. Remote Monitoring and Control

Remote monitoring and control have become integral to modern heavy load-handling systems. The integration of IoT (Internet of Things) technology and cloud-based platforms enables operators to monitor the status and performance of heavy load-handling equipment from anywhere in the world.

By accessing real-time data on load conditions, equipment health, and operational parameters, operators can make informed decisions, optimize workflows, and respond quickly to any issues or anomalies. This level of remote visibility and control enhances operational efficiency and minimizes downtime.

For example, an air pallet system equipped with remote monitoring capabilities can alert operators to potential issues such as low air pressure or system malfunctions, allowing for proactive maintenance and preventing costly breakdowns.

3. Improved Energy Efficiency

As industries increasingly focus on sustainability and energy conservation, heavy load-handling systems have seen advancements in energy-efficient design. This not only reduces operational costs but also lowers the environmental impact of heavy load-handling operations.

Energy-efficient air compressors with variable frequency drives (VFDs) have become the standard, allowing for precise control of air supply and reducing wasted energy. Additionally, heavy load handling systems are designed with energy-saving features such as regenerative braking and power regeneration, which harness energy during deceleration or load lowering and use it to power other system components.

4. Enhanced Safety Features

Safety remains a paramount concern in heavy load handling operations, and modern systems have introduced advanced safety features to mitigate risks. These features include collision avoidance systems, load monitoring sensors, and emergency stop mechanisms.

Collision avoidance systems utilize sensors and cameras to detect potential collisions and automatically adjust the equipment’s trajectory or trigger an emergency stop. Load monitoring sensors provide real-time data on load conditions, ensuring that the equipment operates within safe load limits.

Moreover, heavy-duty transporters have integrated advanced safety systems that incorporate redundancy and fail-safe mechanisms to prevent accidents during the transport of exceptionally heavy loads. These safety enhancements have significantly reduced the risk of accidents and injuries in heavy load-handling operations.

Air Bearings: A Revolutionary Approach To Heavy Load Handling

Air Bearings: A Revolutionary Approach To Heavy Load Handling

Air bearings have revolutionized heavy load handling by providing an innovative and efficient method for moving heavy objects with minimal friction. These systems use compressed air to create a thin air film between the load and the ground, allowing for smooth and precise movement. Let’s take a closer look at some of the equipment that utilizes air bearings:

1. Lift Decks

Lift decks are innovative solutions that take heavy load handling to new heights, quite literally. These systems consist of a platform with hydraulic or pneumatic lifting capabilities, allowing for precise elevation of heavy loads. Lift decks are widely used in industries such as manufacturing, construction, and logistics, where vertical movement of loads is crucial.

One of the primary advantages of lift decks is their ability to optimize space utilization. By efficiently stacking heavy loads vertically, they enable businesses to make the most of their available floor space. This is particularly valuable in warehouses and manufacturing facilities where space is often at a premium.

Lift decks are also known for their adaptability. They can be customized to accommodate various load sizes and shapes, making them versatile solutions for a wide range of applications. Additionally, their precise positioning capabilities enhance operational efficiency and reduce the risk of accidents associated with heavy load handling.

2. Air Bearings

Air bearings, in general, play a pivotal role in heavy load-handling systems. These ingenious devices utilize compressed air to create a thin air film between the load and the supporting surface, allowing for effortless movement in any direction. While air bearing tools mentioned earlier focus on point-to-point movement, air bearings offer a broader range of applications.

Air bearings are particularly valuable in industries where precision and delicate handling of heavy loads are paramount. The semiconductor manufacturing industry, for example, relies heavily on air bearings to move delicate silicon wafers without causing damage. Similarly, aerospace manufacturers use air bearings to transport large and fragile components with precision.

Another key benefit of air bearings is their ability to distribute the load evenly, minimizing stress on the load and reducing the risk of deformation or damage. This is especially important when handling sensitive materials or intricate machinery components.

3. Air Compressors

3. Air Compressors

Air compressors are the unsung heroes of heavy load handling systems. These machines are responsible for generating the pressurized air required to operate air-bearing tools, air-lifting bags, and other pneumatic devices essential for heavy load handling.

The choice of an appropriate air compressor is crucial, as it directly impacts the performance of the entire system. Factors such as air pressure, flow rate, and capacity must be carefully considered to ensure optimal operation. Industrial-grade air compressors are designed to meet the demanding needs of heavy load handling systems, providing reliable and consistent air supply.

Moreover, advances in air compressor technology have led to the development of energy-efficient models, reducing operational costs and environmental impact. Variable frequency drives (VFDs) and smart control systems enable precise control over air compressor operations, ensuring that compressed air is delivered efficiently and only when needed.

4. Air Lifting Bags

Air lifting bags are specialized devices designed to lift and position heavy loads with exceptional precision and safety. These bags, often made of durable and tear-resistant materials, are inflated with compressed air to create a lifting force that can be precisely controlled.

One of the key advantages of airlifting bags is their ability to lift loads in a controlled and gradual manner. This is particularly important when handling delicate or sensitive equipment that cannot withstand sudden jolts or impacts. Air lifting bags are widely used in applications such as rigging, machinery installation, and even underwater salvage operations.

These bags are available in various sizes and configurations to suit different load requirements, making them versatile tools for heavy load handling. Additionally, their compact and portable nature allows for easy deployment in tight or confined spaces where traditional lifting equipment may struggle to access.

5. Air Pallets

5. Air Pallets

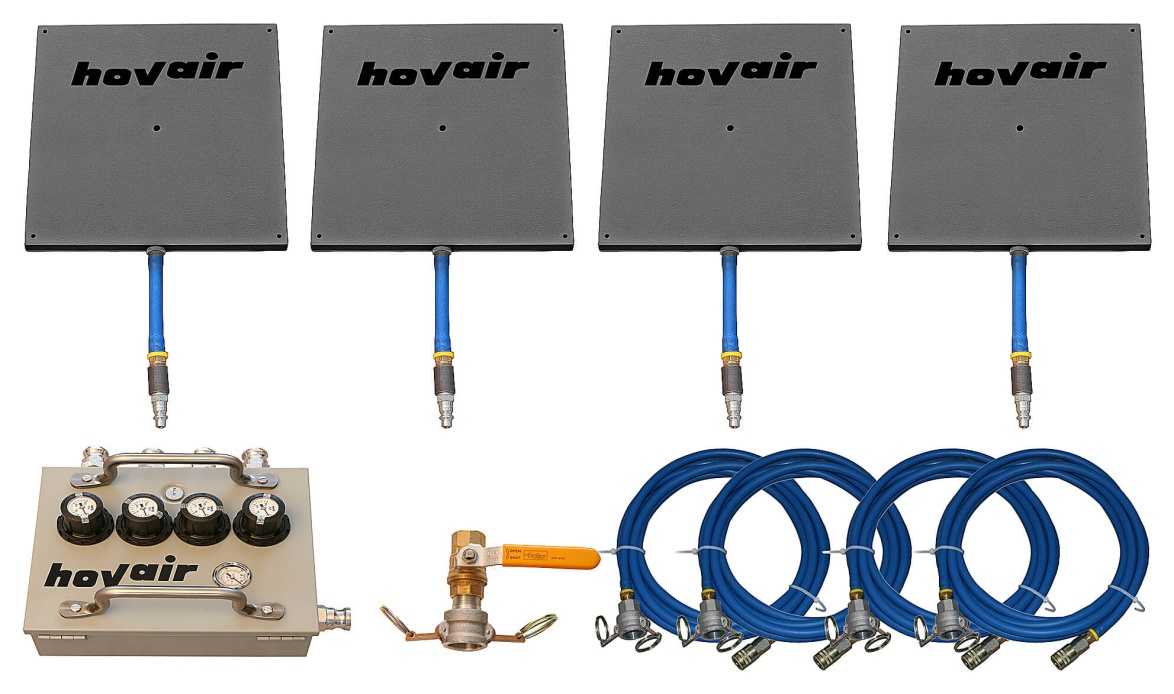

Air pallets are another ingenious solution in the realm of heavy load-handling systems. These pallets consist of a platform equipped with air bearings that provide frictionless movement. Air pallets are ideal for applications where precise positioning and mobility are essential, such as in cleanrooms, manufacturing lines, and assembly stations.

One of the standout features of air pallets is their ability to move heavy loads horizontally with ease. Operators can effortlessly slide heavy machinery or equipment into position without the need for manual labor or the risk of strain-related injuries. This not only enhances operational efficiency but also minimizes downtime during reconfiguration or setup processes.

Air pallets are available in various load capacities, ensuring that they can accommodate a wide range of heavy loads. Their versatility and ease of use make them a valuable addition to any modern industrial facility.

6. Aluminum Transporters

Aluminum transporters are heavy load handling systems that combine the strength required for handling heavy loads with the lightweight properties of aluminum. These transporters are designed to be durable yet easy to maneuver, making them a practical choice for industries where both load capacity and agility are essential.

One of the primary advantages of aluminum transporters is their excellent strength-to-weight ratio. This means they can handle substantial loads while remaining relatively lightweight, reducing the strain on operators and improving overall efficiency. Additionally, the corrosion-resistant properties of aluminum make these transporters suitable for use in challenging environments, including outdoor applications.

The modular design of aluminum transporters allows for customization to meet specific load requirements and operational needs. This flexibility ensures that they can adapt to the diverse demands of modern industry, whether in automotive manufacturing, aerospace, or logistics.

7. Vehicle Turntables and Industrial Turntables

7. Vehicle Turntables and Industrial Turntables

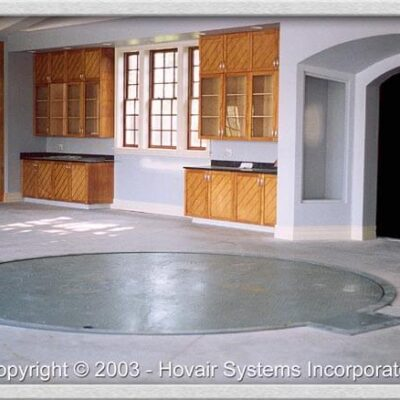

Vehicle turntables and industrial turntables are heavy load-handling systems designed to simplify the process of rotating heavy loads. These turntables come in various sizes and configurations, catering to both small-scale and large-scale applications.

Vehicle turntables are commonly used in automotive showrooms and service centers, allowing for easy positioning and display of vehicles. These turntables can accommodate various vehicle sizes and weights, making them an invaluable tool for showcasing cars and improving showroom efficiency.

Industrial turntables, on the other hand, are utilized in manufacturing and logistics to streamline the process of rotating heavy machinery, equipment, or materials. They enhance productivity by eliminating the need for manual repositioning, reducing labor costs, and minimizing the risk of workplace injuries.

Both vehicle and industrial turntables can be automated, allowing for precise control over the rotation process. This automation not only enhances operational efficiency but also improves safety by minimizing human involvement in potentially hazardous tasks.

8. Heavy Duty Transporters

8. Heavy Duty Transporters

Heavy-duty transporters represent the pinnacle of heavy load handling systems. These robust and rugged vehicles are designed to transport exceptionally heavy and oversized loads with ease. Heavy-duty transporters are equipped with multiple wheels or tracks and often feature hydraulic or electric propulsion systems.

One of the standout features of heavy-duty transporters is their immense load-carrying capacity. These machines can handle loads weighing hundreds of tons, making them indispensable in industries such as shipbuilding, mining, and construction. Their ability to transport large and unwieldy loads over rough terrain or within confined spaces ensures that even the most challenging projects can be accomplished efficiently.

Additionally, heavy-duty transporters can be equipped with advanced control systems, allowing for precise and synchronized movement of multiple units. This level of control is essential when transporting massive loads that require careful coordination.

As industries continue to evolve and demand even greater efficiency, precision, and sustainability, heavy load-handling equipment will undoubtedly keep pushing the boundaries of innovation, and who better than Hovair Systems to help you adopt that?

As industries continue to evolve and demand even greater efficiency, precision, and sustainability, heavy load-handling equipment will undoubtedly keep pushing the boundaries of innovation, and who better than Hovair Systems to help you adopt that?

We are one of the top-tier manufacturers and suppliers of material handling equipment and ergonomic solutions powered by air-bearing technology. Our wide range of material handling equipment includes lift decks, air beams, air compressors, air bearing kits, air bearings, and a lot more. Get in touch with us today and learn more about our solutions in detail.

2. Remote Monitoring and Control

2. Remote Monitoring and Control Air Bearings: A Revolutionary Approach To Heavy Load Handling

Air Bearings: A Revolutionary Approach To Heavy Load Handling 3. Air Compressors

3. Air Compressors 5. Air Pallets

5. Air Pallets 7. Vehicle Turntables and Industrial Turntables

7. Vehicle Turntables and Industrial Turntables 8. Heavy Duty Transporters

8. Heavy Duty Transporters