In the traditional past – back in the day, machine moving tools included castors, wheels, skids and sleds all of which had to be pulled along by a forklift truck or similar. And as they traveled across floor surfaces, these tools caused no end of damage to the floors. Those days should be in the past as modern machine companies move to Air Skates Load Moving Equipment..

The modern way of moving machines is by using air skates load moving equipment. These air skates fit snugly underneath the machines or the heavy loads that are to be moved.

Air skates load moving equipment is a series of components that fir together to form a air skate module. The main component of the air skate is the air bearing which is fitted to the bottom of the module. See images below:

The black diaphragm fitted to the bottom of each module is the powerhouse of the whole exercise. It is what defines the weight capacity of the air bearings and the size of the machines it can lift and move.

When a set of air skates are fitted underneath a heavy machine in order to move it, the skate modules are taking the weight of the machine. The air skates are designed to operate pneumatically with compressed air. When air is powered into each air skate it causes the air skate to inflate. When the skate is fully inflated the excess compressed air is then repelled back by the floor surface and this causes the air skate to rise and float on the floor surface. When in flotation state, the machine will be lifted and can then be moved off to a different destination.

The image above shows a heavy Caterpillar machine being moved with Hovair Systems air skates.

When it comes to lifting and moving heavy objects and machines, there is little to compete with modern air skates load moving equipment.

Air skates lifting equipment is available in sets of four or six air skate load modules. The only power source needed is compressed air which most industrial locations have in-house to power other tools. Using only compressed air (pneumatic), air skates load moving equipment can produce tremendous lifting power to handle the largest and most awkward heavy objects and machines.

Air skates – also known as air casters, air cushions and air sleds – are the usual tools of choice for moving heavy objects and machines. They can easily out-perform any forklift or overhead crane in most indoor locations. With weight capacities starting at 1000 pounds, they can range right up to 100 tons and all points in between.

There are not many machines that an air skates load moving equipment cannot handle.

The versatility of air skate lifting equipment allows them to be placed in strategic positions beneath the machines or heavy loads they are moving. This helps to take care of any uneven load distribution properties of the machine.

Air skate load moving equipment is very versatile in as much as its air skate are not required to have a fixed position underneath the machines they are moving. The great benefit to this is that you can move a machine that has differing weight proportions. For instance, one side may weight several tons more than the other side, and with the versatility of the air casters, they can be placed at the correct places beneath a machine to allow support under the machine in the correct places. You can use any number of air skates beneath many locations of the machine you are going to move.

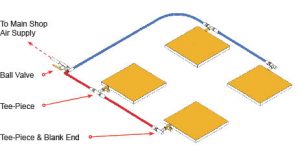

Below right, is a diagram of a typical four-station air skate machine moving layout. These air skate positions can be altered to suit the weight of the machine they are going to use. Using as many air skate modules as you need, you can place them in different locations beneath the machine to suit the properties of that machine. There is very little that is beyond these tremendous load moving tools.

Air skate are used in series of four or six and assembled into complete air skate machine and lifting equipment via air line hoses, valves, tee-pieces and other hardware. See below, right.

This form of load moving is known as air film technology.