Aluminum Transporters

Aluminum Transporters are air pallets that mobilize standard loads. They are easily maneuver in any direction, and prove to be a cost-effective means of transport.

Aluminum Vehicle Transporters are powered by Air Bearings, which can glide loads across a surface. Size and weight capacities for air bearings will vary. A standard set of four A-type bearings generally supports a capacity of 4,000 lbs at dimensions of 4ft x 3 ft.

Transporters can be designed to different needs and specifications. However, they are ideal when applied to standard sized load moving. They provide a swift and convenient means of moving objects across a factory or warehouse floor.

Aluminum Transporters

Watch this demonstration Video to see our products in use. Transporters can be fitted with A-Type or B-Type B-type air bearings. Air flow is controlled through a manifold at one end of the transporter, where an air hose attaches.

A-type air bearings are designed to move loads laterally across floor surfaces with “just enough” lift to cause the load to clear the floor and float smoothly.

.

B-type air bearings are designed to lift loads vertically off their base. They move laterally across surfaces, then are dropped into position. They function the same as A-type bearings, but lift two to three times as much when pressurized.

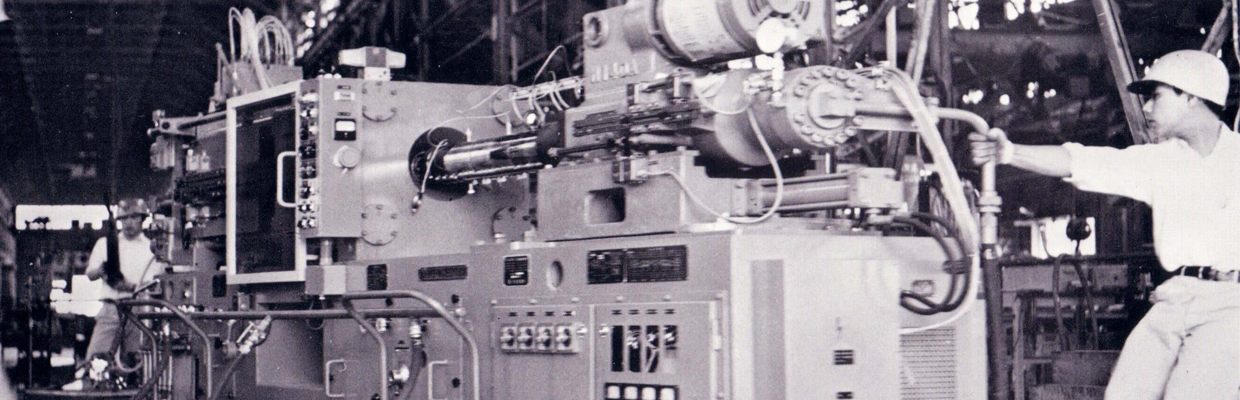

Shown here are pictures of a transporter being used in a safety crash testing facility. Transporters can quickly align vehicles into different positions, and offered more accuracy and time efficiency than forklifts.