Assuming you have read the What Is An Air Bearing Article, we can now take a look at how an air bearing actually works. We can see from the blow-up illustration below how an air bearing is assembled. But what happens next; how does the air bearing work.

Generally an air bearing load module is grouped with three or more other air bearings modules, and connected together to form what is knows as an load moving (or machine moving) system. Below is a typical load moving system footprint all ready to have a load placed on to it.

Once the air bearing modules are formed into a footprint roughly the same size as the load they are going to move, it is time to introduce air to the system. This is done by connecting a compressed air supply pipe from the company’s compressor to the system’s entry point at the on/off ball valve. Making sure that all air flow control valves located on the side of each load module are fully shut, it is safe to turn on the air supply at the system entry ball valve. By doing this compressed air is allowed to flow to each individual load module. For this article’s purpose, we’ll take just one load module as an example, but the procedure needs to be done to all load modules in the system.

Choose a load module and open its air flow control valve about half a turn or so. See image to your right. You should hear the air starting to enter the load module. At this stage the compressed air will travel through a series of internal channels until it reaches the air bearing’s diaphragm – the black element of the module. When the diaphragm is reached the compressed air is forced to enter the diaphragm. Remember, there is a constant supply of compressed air forcing its way into the diaphragm at this time. This is why we need to be able to control and manage the air that enters each load module.

The amount of air allowed into the load module will depend on the weight capacity of the air bearings being used and the load going to be moved. This is why we have these air flow control valves to help manage the amount of air we’ll be using. When initially turning on the flow control valve we should do it incrementally with the other modules in the system – do each valve in turn the same amount. Eventually the correct amount of air will be reached and the load modules will start to raise and float the load off the floor.

When the incoming air reaches the (black) diaphragm this causes the air bearing to inflate – because of the incoming air trying to blow it up like a balloon. When the air bearing has inflated to its maximum for the weight being carried, the remaining air has nowhere else to go because of the pressure of the following compressed air. The air (like water) will search for an exit and it should quickly find the exhaust holes of the air bearing. You can clearly see the exhaust holes in the image to the right.

The load you are going to be moving should already be placed on the air modules before the air to the system is turned on. The load will be pressing down on the load modules. The modules cannot move at all because of the load’s weight. So when the air bearing starts to inflate, the black diaphragm expands downwards and forms a tight seal with the floor surface.

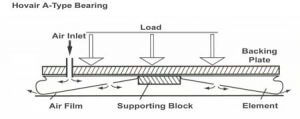

Below is a perfect example that illustrates how the air bearings work.

The air inlet simulated the position of the air flow control valve at the entry to the load module.

The load is already placed upon the load modules.

The air enters the air bearing at the inlet point and finds its way to an exit point inside the diaphragm.

As it enters the main diaphragm area it cause the air bearing to form a seal with the floor.

The seal is formed at the extreme edge of the load module – as shown.

The compressed air is eventually repelled away from the floor surface thus causing the air bearings to raise and take the load up with it.

When the air has raised to its limit, the excess air will escape from the sides of the air bearing.

The air bearing will retain sufficient air to keep the load floating.