Spacecraft

The aerospace industry has long enjoyed the benefits of our load moving systems for various applications. Air bearing systems provide convenient solutions across stages of testing and assembly of spacecraft.

Hovair In History

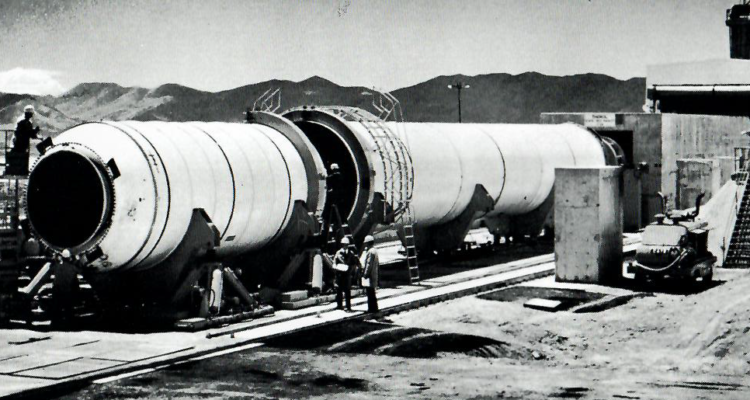

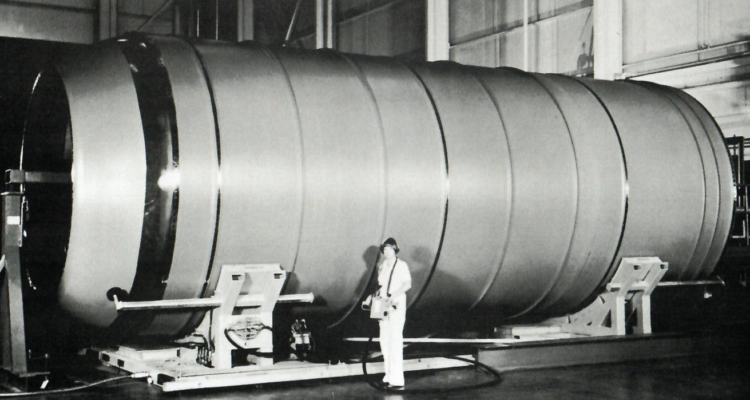

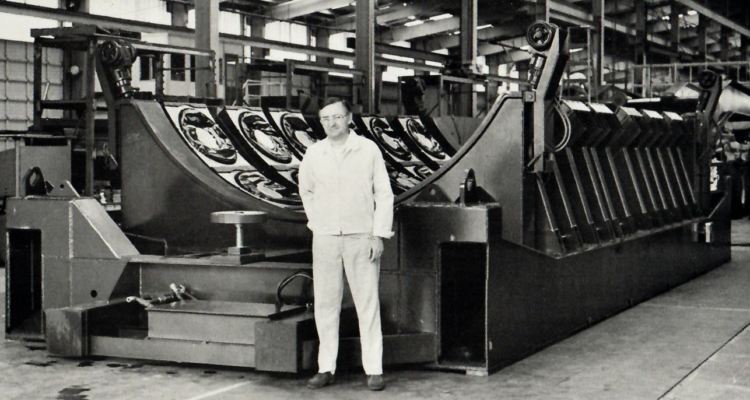

Rocket assembly made easy: During the space shuttle program, Hovair Systems created a custom rocket handling dolly. This device was able to transport heavy motor sections. The transporter, as well as the cradle, used air bearings to move and maneuver parts. This solution offered both rotation and precision movement during the assembly process.

Applications:

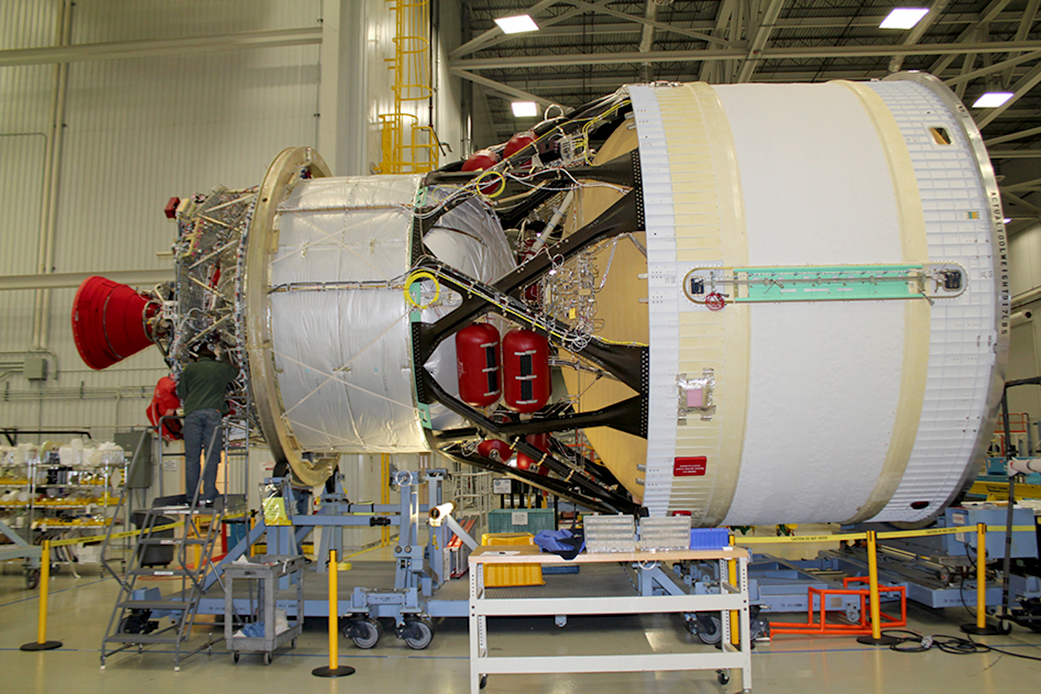

Engine Assembly – Transporters can be used to carry heavy engines down the assembly line. These devices can easily re-position components, allowing access to other areas.

Testing Stage – Our client’s have used turntables to set up multiple staged tests ahead of time. This meant less time was spent between tests to reset the scenario. Our client saved 40% of their usual cycle time, and required one less operator for the job.

Weight Reduction – Our products reduce the weight of heavy objects by floating on compressed air. This makes big moves quicker and easier, and will protect floor coating along the way.